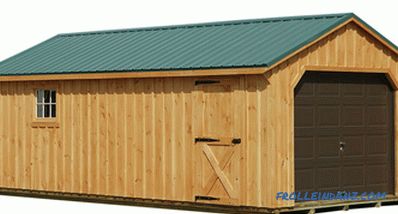

It is quite possible to build a wooden garage with your own hands, and in a fairly short time. It will harmoniously look at the site where all other buildings are made of wood. It remains only to choose how to build a garage out of wood.

The wooden garage will look good on a site where all other buildings are made of wood.

Preliminary preparation

The preparatory stage for the construction of a wooden garage includes designing, calculating materials, and marking the structure on site.

The project of a garage and the calculation of building materials will not only speed up the process of building a garage, but also eliminate the extra costs of purchasing wood. The project should take into account the number of cars that are planned to be placed in the garage, the presence or absence of a carport to store the car in the summer, and the construction of an attic that can be located above the garage.

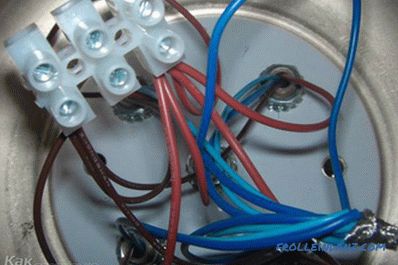

Wiring diagram of a wooden garage with dimensions.

The project can display lighting devices around the future garage, tracks and driveways, as well as the opening path of the gate to avoid inconvenience after construction or during its construction. The project reflects the type of building - whether it will be an independent building or a garage will be adjacent to one of the walls of an existing house. If the garage will be combined with the house, then you need to calculate building materials.

Of course, the calculation of the required amount of building materials and varieties is determined depending on the chosen construction technology of the wooden garage. If the garage is a frame, then it is a bar of different section, OSB sheets or plywood, insulation, screws, metal corners. If the log technology is taken as a basis, then it is cylindered logs, insulation. In this case, the necessary materials for the roof: boards for battens, roofing material (shingles, decking, metal).

After the calculations made, you need to perform markup on the spot. This can be done with the help of pegs and twine. In addition to build a garage, you will need:

- tape measure;

- screwdriver;

- ax;

- hammer;

- concrete mixer and others.

The Foundation and its nuances of construction

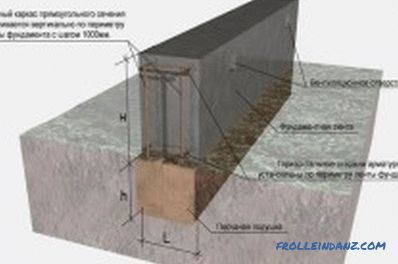

The strip footing under the garage.

The foundation is the basis for any building. Garage is no exception. The foundation for a wooden garage on the frame or log technology should not be very powerful, since the structure will be light enough. Monolithic construction of the foundation during the construction of the garage is necessary only if the groundwater occurs at a depth of less than 10 m.

In all other cases, a strip foundation will suffice. Its depth is 50 cm, width is 20 cm, height above the ground is not less than 20 cm. This is quite enough to withstand the upcoming load of the garage building for a long time. A drainage cushion of 5-7 cm in height will serve as a drainage.

For the construction of the foundation, a trench is dug by previously laid out markings on the specified dimensions. Next, formwork is installed. As it can be used boards, which are tightly interconnected by screw studs in order to avoid possible leaks.

After that, reinforcement rods with a diameter of 10 mm are placed, which are connected to each other with wire or plastic clamps. Concrete mortar, which is a mixture of cement, sand, crushed stone of fine fraction and water, pour the foundation. During pouring, the solution must be primed to prevent the formation of voids. After that, it is necessary to give the foundation to completely harden for 10-15 days.

Walls, floor, roof of the garage

The wooden floor in the garage is laid on the logs.

The floor for a log garage can be laid on the bottom trim. Previously on the foundation should put a waterproofing layer - roofing material. Mortgage timber fastened in the corners of the way in the paw or on the root (plug-in) spike. The choice of attachment depends on skill and skill. The main thing - the connection must be reliable.

Next, lags (bar 150x100) are slammed into the bottom trim, the distance between which does not exceed 50 cm. If the logs are quite long and to avoid bending the floor, props must be installed under them along their entire length. Props often serve as brick columns. The distance between such columns is not more than 60 cm. They are also covered with a layer of roofing material. It should be noted that the logs, bars of the lower strapping must be treated with antiseptics.

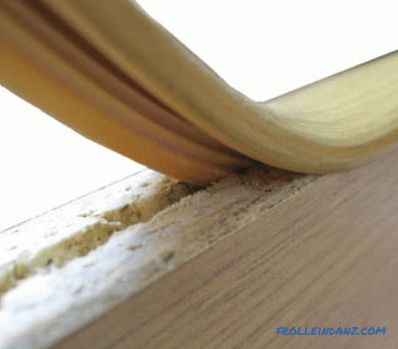

Further, in the construction of walls, the connection of the timber is used the same as in the lower piping. The rows are fastened with the help of dowels - wedges made of hard wood, which are driven into pre-drilled holes. Nagel embedded in the timber to avoid the formation of cracks during drying.

In the upper ring, cuts are made for the rafter bars.

On the wooden garage you can make a roof from a profiled sheet.

The shape of the roof depends on the design and dimensions of the garage. When adjoining a garage, it is wiser to make a lean-to roof, for a detached garage - a dual-slope. Next, perform the crate, a layer of roofing material across the crate, and then - the roofing material.

For the floors take a tongue-and-groove board, fix it on the logs with nails (self-tapping screws). After that, all the space inside the garage is covered with a special fire-fighting compound. For safety, floors can be covered with metal sheets, at least in the places of possible spilling of flammable liquids.

How to build a frame type garage: recommendations for construction

Foundation

For such a garage, it is preferable to perform a solid foundation. This is due to the fact that the floors are quite difficult to securely fix with a very light construction of the frame garage. Monolithic foundation will play the role of sex.

For a monolithic foundation, it is necessary to remove the soil by marking and build a formwork around the perimeter with a height of 30-40 cm. The bottom layer of the foundation will be sand and gravel, which will be poured with water and tamped when laid. The height of the layer - 20 cm. Next, there is a layer of waterproofing - waterproof membrane or roofing material.

After the reinforcement has been laid, its binding the foundation is poured with concrete. At the same time his ram. After solidification during the month, the construction of the garage can be continued.

Walls, roof of a frame garage

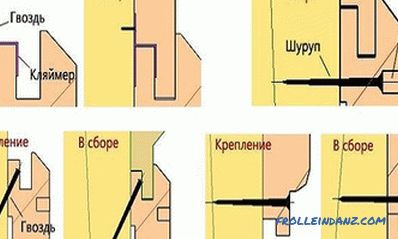

Corner posts are placed on the bottom trim, which is made of 150x100 mm timber. However, the strapping can and not perform, and mount the rack directly to the foundation with metal corners. Support beams must be vertically aligned on the building level. Guides, which are mounted perpendicular to the posts, can be boards with a section of 100x40 mm. The distance between them does not exceed 1 m. When fastening the guides, nothing should protrude beyond the rack.

Roof beams are fastened to the top trim in pre-sawn grooves. They are fastened with metal brackets, which ensures reliability. The distance between the rafters is no more than 1 m. A crate is laid on them, then a layer of waterproofing (roofing material), and then a roofing material.

Between racks the heater is insulated - heat insulating mats or foam. On the inside of the garage, a vapor barrier film is attached to the racks by a construction steepler. From the outside, on top of the insulation, a layer of vapor barrier is fixed, and then waterproofing. Further, the frame can be sheathed with OSB sheets or plywood from the inside, siding or clapboard for exterior work.

How the garage will end up is the choice of everyone. But the construction of a wooden garage with their own hands - quite a real event.

Didn't find the answer in the article? More information on the topic:

-

How to make a self-leveling floor on a wooden floor

Recommendations for how to pour the self-leveling floor onto the wooden floor with your own hands. Tools and materials needed for work. Preparation of the basis for filling by solution.

-

How wooden shelves are made with your own hands

Wooden shelves with their own hands are done in a short time. To do this, select the appropriate material, determine the size, choose a design. Then the assembly is carried out.

-

How to assemble a log house for a bath?

Recommendations on how to build a log house for a bath, choose lumber and prepare it. The nuances and technologies of installation of middle, lower and upper rims, as well as methods for their additional fastening.