In the current age of innovation and modern technology, there is a gradual replacement of artificial materials with natural ones. Thus, parts of the glass, concrete or metal trim are replaced with warm, natural materials that carry naturalness and a favorable microclimate into the living space. If for industrial and industrial enterprises artificial finishing materials remain relevant, then residential elements are made of wood. Wood trim technology originated a long time ago, but it remains relevant today.

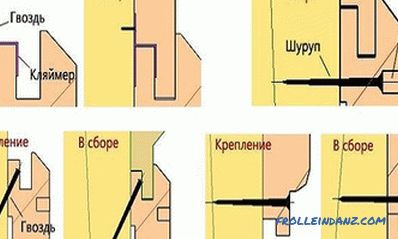

Mounting plans for wall paneling.

The material used for plating

Different wood species allow you to vary the interior of the room. Aspen panels, birch, lime, larch bars have a different structure, so for the owners there is a large choice of material. But in some cases, experienced builders recommend using plastic panels: in the bathroom, toilet or balcony it is possible to mount plastic. In addition to moisture resistance, it is worth noting the ease of maintenance and high speed installation. But low environmental friendliness does not allow to use it for installation in living rooms, and possible mechanical damage significantly reduces the service life. For these reasons, many prefer to finish their living rooms with wooden panels - clapboard.

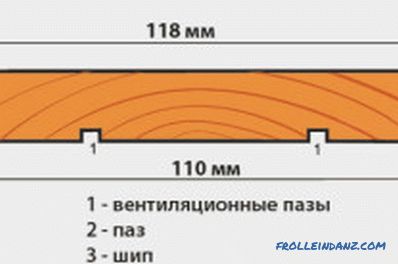

Types of lining.

When installing wooden lining, you need to study the following recommendations and adhere to them so that the efforts made are not in vain:

- Only low-temperature rooms are suitable for mounting pine wood, because when heated, they begin to release resins, which negatively affects the indoor microclimate of the room.

- Provide a ventilation gap between the bars and the wall to provide ventilation.

- If the base of the wall is susceptible to moisture, it should be treated with a moisture-proof composition, and wooden guides should be treated with a primer to prevent rotting and damage by small pests.

How to start installation?

Preparation of the material and base, construction of the frame

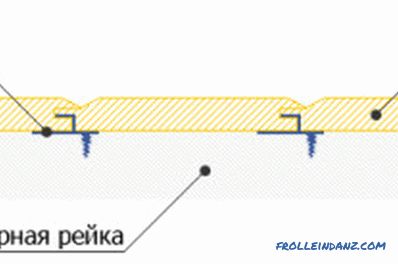

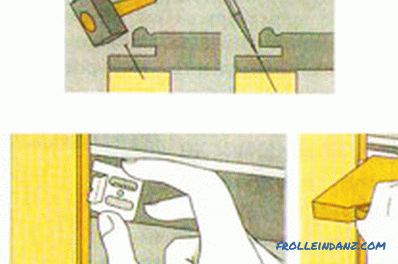

The scheme of fastening wooden lining on klyymery.

Installation of panels can be carried out on wooden or metal guides. Metal does not need preliminary preparation. And wooden elements are treated with moisture-bio-and fire-retardant impregnation. This is necessary to increase the life of not only the hidden part of the finish, but also the front.

Wood panels are also treated with special compositions and, after complete drying, are brought into the room where they will be installed a day before the work begins. This is necessary in order for the products to adapt to the temperature of the room and no further distortion of them occurs.

The method of installation causes the preparation of load-bearing walls. The panels can be placed horizontally, vertically, diagonally. Proceeding from the chosen method of fastening, the bearing bars are fixed. Regardless of the clapboard cladding, they should be perpendicular to the panels.

If the base is not processed, has irregularities, then it should be pre-leveled. In the case when the base is smooth and clean, then wall decoration with your own hands can occur without the construction of a frame. The fastener runs directly on this base.

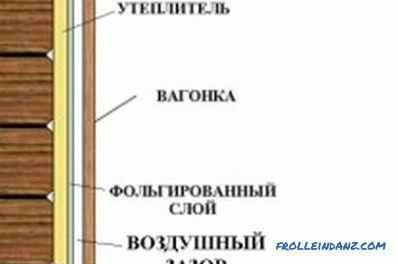

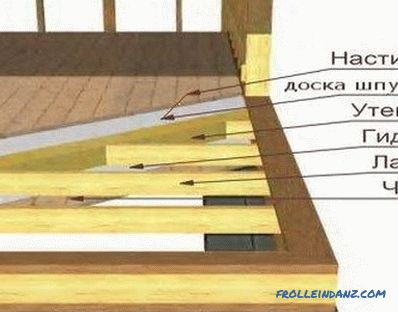

Lining device.

The sequence of the frame construction is as follows:

- The supporting elements of the frame are selected depending on the quality of the walls, the use of sound or heat insulation materials. For its construction, products of at least 40 * 20 mm are used. This is necessary for sufficient ventilation clearance under the lining.

- The distance between the bars is taken at least 40-50 cm, the length is due to the height of the room. It will be better if you use one bar, thus the structure provides rigidity and strength.

- In the event that the room needs additional thermal insulation, the height of the beam is taken based on the thickness of the insulation. Without necessity, it is not necessary to select the useful area of the room.

- The construction is fastened to the wooden bases with self-tapping screws, to concrete and brick with dowels.

- Immediately near the windows and doors, additional bars are fixed, on which the wooden panel and decorative corner or platband will be fixed.

- All places where electrical appliances exit must be de-energized and dismantled. After fixing the panels, the holes for sockets and switches are cut out by a crown.

When placing the supporting beams, they should be fixed strictly vertically.

The construction level or plumb can help the master in this. If the need arises to grow the beam, then the next one is fixed at a distance of 2-3 cm. A small space provides the necessary ventilation.The frame is fixed with a constant pitch of 50-60 cm.

When laying the insulation material, the beams are positioned a few centimeters smaller so that the slab fits tightly between them. Also the framework can serve for laying of communication networks: water supply, sewerage or electricity. Electrical cable is recommended to lay in a corrugated pipe in order to avoid fire and damage to the cable. The laid insulation must be protected with a vapor barrier.

Fastening the cladding

Wooden clapboard wall trim.

Nails, screws, or clips are used to fix the wooden panels. Regardless of which fastening methods are chosen, they should all be hidden and not violate the front side of the coating:

- Nails are used with a reduced cap and are hammered into the groove into which the next bar will be inserted. It is hammered along an oblique line, a notch is used to deepen the cap in order not to damage the front side.

- The clamps are much more difficult to fasten, but they allow you to disassemble the panels without compromising their integrity and quality.

Wall decoration begins from the most important point - the fastening of the first panel. Since wall cladding can be done both horizontally and vertically, then you need to move from top to bottom or from left to right, respectively. The first panel is trimmed and fastened on the front side with nails as close as possible to a corner or ceiling. The next panel is inserted into it and fixed with a clip. The fastener is located at the level of the carrier profile.

If the length of one bar is not enough, then it can be grown from other segments. Spliced pieces must be placed at the level of the supporting profile and fasten each of the pieces at the junction. The structure assembled in this way acquires the necessary rigidity, and in the process of operation it will not be afraid of loads.

Mounting steps for lining.

The last strip is cut to the width and fastened on the front side with nails with a small hat.

The finish and starting strips are moved away from the walls and ceiling by at least 5 mm. This is necessary for the free movement of air under the structure. The nails on the starting and finishing strips, as well as on the window and door ends, are covered with a decorative baseboard or decorative slats.

Using the advice on installation, the work will be carried out efficiently and quickly, which will save on the involvement of the construction team. The decoration of the walls with wooden clapboard gives the room extraordinary natural comfort, warmth and uniqueness.

Finishing surface

After fixing all the decorative elements, the surface should be lacquered, which will increase the life of the new coating and preserve the wood structure. For preventive purposes, wanting to extend the life of a wooden coating, it is necessary to carry out surface treatment with moisture and bioprotective solutions once every few years. Such measures will allow to keep the living room in a beautiful and well-groomed form.

Didn't find the answer in the article? More information on the topic:

-

Features of the device for flooring on wooden beams

The device of a floor on wooden beams is 1 of 2 possible variants of its construction. Floor beams are important structural elements of the structure. To lay the floor on them need to special rules.

-

Wooden house: do-it-yourself process

How to build a wooden house with your own hands? Choose a suitable project, purchase materials and tools and, following the recommendations, start construction. Recommendations further.