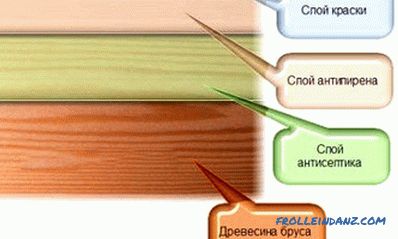

Wood processing is performed in order to increase the service life of this material. Impregnation with special oils, staining, waxing, varnishing prevent the processes of decay and deformation, as well as damage to wood by insects. Brushing shows the texture of wood, gives it the look of old wood. How to handle a tree - you decide, each of these methods has its advantages and disadvantages.

The optimal tree protection scheme.

Oil and waxing

You will need:

- linseed oil;

- beeswax;

- flautse ( wide flat brush);

- sandpaper with fine grain;

- rags.

Wood treatment methods are different, but they have one goal - to prevent rotting, mold, drying, insect damage, and also to give the surface a beautiful finished look. The use of special oils (drying oil) and beeswax allows you to preserve the structure of the material, gives it shine and strength, and increases the service life.

The depth of impregnation of flaxseed oil is 2 mm, which is enough to form a protective layer.

It is possible to process wood with minimal costs using linseed or hemp oil. Before starting work, it is necessary to clean the wood from dirt and dust, completely remove the previous coating, sand the surface with fine grain sandpaper. Experts recommend heating flaxseed oil in a water bath, but you can do without this procedure. Apply the oil either with the help of a flautz, or rub it into the wood with emery paper. It is important to follow the direction of the brush, apply oil only along the fibers. The work is left for a day, after which the oil is applied again, the procedure is repeated until the desired result is achieved. Small products immersed in oil for several days.

There are other ways of processing, for example, wood coating with a mixture of linseed oil and beeswax. All components are melted in a water bath, then applied to the surface with a brush or cloth. In order to give the wood a certain shade, add color to the composition of a suitable color. This method has a significant drawback - very slow drying. You can speed up the process if you add a desiccant (sold in art stores) or buy ready-made oil (drying oil), which contains polymerization accelerators and antifungal additives.

Solid wax color palette for wood.

Wood can only be treated with one wax. Modern industry offers color, colorless, matte, semi-matte, glossy compounds that not only strengthen, but also favorably emphasize the texture of wood. To process a large surface, it is necessary to heat the wax in a water bath (in this case it is applied with a wide brush). Cold wax is rubbed into the wood in a thin layer with a cloth, left for about a day, then the surface is waxed again. You can combine colorless and tinted wax, for example, to treat the edges with a dark composition, and the middle of the product - transparent. After the wax dries, it is necessary to polish the surface with a wool cloth (felt).

Wood Brushing

You will need:

- gas burner;

- metal brush;

- work gloves;

- flautz.

The brushing method makes it possible to emphasize the structure favorably, to give the tree a touch of antiquity, it consists in removing soft fibers (from the upper layer) with the help of a rigid metal brush. For this purpose, select a tree with clearly defined annual rings, the presence of knots, eyes and other flaws is welcome. Such types of wood as pine, spruce, oak, linden, walnut are best suited for brushing. The following are considered unsuitable: cherry, pear, alder, juniper, teak, beech.

Brushing is superficial and deep, performed with and without roasting. At home it is much easier to use the unburned method. The tree is cleaned of dust and dirt, wet the surface with water, after about 15 minutes they begin to comb the fibers with an iron brush.

It is necessary to move along the direction of the fibers, while it is desirable to repeat the pattern of annual rings (the furrows should not be perfectly smooth).

Patterns of hand movement for waxing wood.

This work is quite dangerous, so it is important to follow safety precautions. The remaining debris is cleaned with a flute (wide brush), moving against the fibers, otherwise the dust will stick to the surface. This is followed by treatment with stain or wax.

For firing, you will need a gas burner, with it using the charcoal surface of the wood. Sometimes in the tree there are so-called resin pockets that can catch fire during firing.In no case should you allow long-term burning of such places, the fire should be immediately extinguished. The degree of charring depends only on your idea; it can be light or completely blacken the surface layer. After that, the fibers are brushed with a metal brush. It is better to work outdoors, as a lot of black dust forms during brushing. At the final stage, the surface is polished using fine emery paper. In some cases, roasting treatment (followed by combing) is repeated several times, thus achieving the effect of an aged tree. If necessary, apply the stain or patina, but you can do without it. The result is fixed with the help of furniture wax.

Wood treatment with wood stain

You will need:

- stain;

- a wide brush;

- fine sandpaper;

- rags.

The stain is applied parallel to the wood fibers, preventing the layers from touching.

Wood treatment with wood stain is one of the most popular finishing methods. Stain is water based or alcohol based, the latter gives a more saturated tone. The alcohol-based composition is applied to a cleaned and sanded surface with a fleetz (wide brush), moving along the fibers in one direction. At the same time trying to put as much as possible stain. After which the product is allowed to dry, if necessary, the operation is repeated. Using the stain of various tones (layer-by-layer application), interesting color effects can be achieved. After the stain dries, the stage of washing begins. It is necessary to remove the excess funds, for this product set at an angle of 30 º, then dip the brush in acetone and pass over the surface (lightly up and down).

To give the tree an effect of antiquity, use the following method. First, the main background color of the stain is applied (water-based), after it is dried, it is passed over the surface with fine emery paper (strictly along the fibers, otherwise the transverse stripes will be visible after processing). The result should be a non-uniform toning with scuffs and bald spots. Then take a water stain of a different color, cover it with wood, allow to dry, and then clean it again with sandpaper. The operation is repeated until the desired tone is achieved. If you plan to make a monochromatic coating using water stain, then it is applied in several layers with a mandatory intermediate drying and treatment with fine emery paper. Wash the extra stain immediately after its application. The excess is simply washed with a damp cloth.

Composition for wood impregnation.

When applying a water stain, you cannot return to the stained place, otherwise dark spots that are difficult to remove will form.

At home, you can prepare a stain that will give the tree an aged look. Small nails or metal shavings are put in a glass jar, poured with vinegar (it is better to use wine), leave for a day, after which the liquid is filtered. If you want to get a darker color, then the exposure time is increased. The resulting solution is used for staining wood. Strong brewing of black tea, coffee, cinnamon and even manganese can be used as a stain. Fix the result with nitrolac. If the treatment used water stain, it is better to take an alkyd or acrylic lacquer.

Wood varnishing

After applying the stain, the surface is treated with a quick-drying nitrolac - this is done in order to lift the nap. The varnish is applied with a thin layer (fast movements). After drying, the tree becomes rough to the touch - this is due to the raised fibers. The surface is polished with fine sandpaper, moving along the wood fibers. The main task is to clean the wood from the rising fibers and make the surface smooth. After that, you can use another furniture lacquer. Continue processing with the same nitrolac is not recommended, as it will dissolve the previous layer.

Next, apply a base coat of varnish, allow it to dry, and then pass over the surface with emery paper. Then, with a damp cloth, remove the remaining dust, again apply a thin layer of varnish. The operation is repeated until the surface is perfectly smooth. In order to achieve a mirror finish, the surface is polished with a piece of felt moistened with oil and alcohol.

For treating wood with varnish it is very important to use a high-quality brush made of dense synthetic nap, which does not crumble when applied and leaves no traces in the form of stripes and bald spots. For aged things do not require careful processing of each layer, as the polished surface does not fit well with the old texture. In this case, it is enough to apply 2-3 layers of matte furniture varnish or wax.

Alcohol-based wood-based varnishes (shellac varnish) are applied with a cotton swab or brush. Cotton swab moistened with varnish, then hold them along the surface along the fibers (only 1 time), next make the next stroke in such a way as to capture the previous one. At the junctions of the strips, the varnish spreads quickly, therefore no stains are formed. Do not use too thick shellac varnish, otherwise dark stripes will form. Processing wood with shellac using a brush is performed in the same way as with a swab. The varnish is applied in 3 layers with the obligatory intermediate drying. Following these tips, you can easily process the wood without the help of experts.

Didn't find the answer in the article? More information on the topic:

-

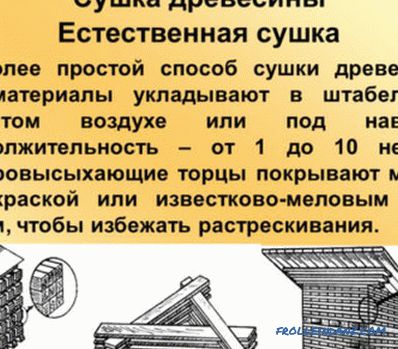

How to dry a tree qualitatively?

Recommendations on how to dry the tree yourself. Rules for proper drying of wood. Drying under atmospheric conditions. Advice of experts on drying wood.