Linoleum is still the most popular floor covering. Types of linoleum on the market have many different colors and textures. This allows you to choose a coating for any interior. The drawing can imitate various materials (wood, tile, stone, etc.) or simply create an original ornament. It has many advantages: low price, environmental safety, durability and ease of installation.

Types of linoleum depending on the material of manufacture

Linoleum from natural materials

Mainly made from wood resin, lime, cork flour and flaxseed oil. Such linoleum is considered to be environmentally friendly, has excellent antistatic properties and is resistant to various bacteria. In addition, it is difficult to ignite and does not absorb greasy drops.

Polyvinyl chloride (PVC) linoleum

Available in several versions: on a fabric, foamed, heat-insulating non-woven bases.

It can be both single-layer and multi-layered. The main disadvantage of PVC linoleum is their large shrinkage, as well as the specific smell, which does not erode for a long time.

Relin or rubber linoleum

A two-layer coating with a base of crushed used rubber or bitumen. The upper part is made of synthetic rubber and a special filler with the addition of pigments. Relin is well resistant to moisture and quite plastic.

Kollokelinovy or nitrocellulose linoleum

It is made without a basis. This is a thin material based on nitrocellulose. The disadvantage of this type of coating is high flammability. The positive qualities include elasticity, moisture resistance and beautiful shine.

Hyphthalic or Alkyd Linoleum

This is a coating based on woven material, alkyd resins and pigments. Such linoleum is more fragile than the others, but it has better sound and heat insulation qualities.

PVC varieties of linoleum, depending on durability and scope of use

Linoleum for household purposes

Used in residential premises. Usually made of polyester or foam. It is quite thin (about 4 mm), has many variants of colors and patterns. Easy to install, soft, unpretentious in operation. But with increased loads and frequent use, it quickly loses its attractive appearance.

Semi-commercial linoleum

Used in hotel rooms, small offices. Often used in the residential sector. The structure of such linoleum is similar to household. However, it has a special protective coating with a thickness of up to 0.7 mm. This greatly increases the service life of the material.

Commercial linoleum

It is selected for rooms with high traffic. The most commonly used polyvinyl chloride coating. Thanks to a durable and reliable upper layer, it serves for a long time and retains its original appearance.

Types of linoleum depending on the structure

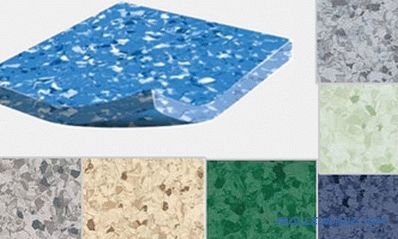

Homogeneous linoleum

Its structure is a homogeneous mixture of PVC granules and dyes. Drawing on such linoleum is not applied on the top layer of the coating, but penetrates it to the full thickness. It is good to use it in places with big passability as linoleum turns out very resistant to deleting.

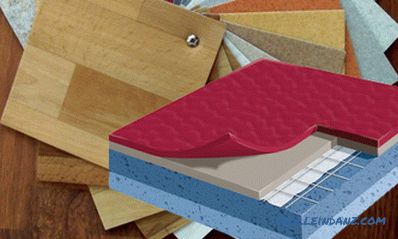

Heterogeneous linoleum

Consists of several layers (up to 6 pieces) of PVC. At the base has fiberglass. The substrate is fabric, non-woven fiber or foam structure.

Baseless linoleum

A relatively thin (from 1.5 to 3 mm) coating that requires a perfectly flat surface for installation. Linoleum is quite cheap and short-lived.

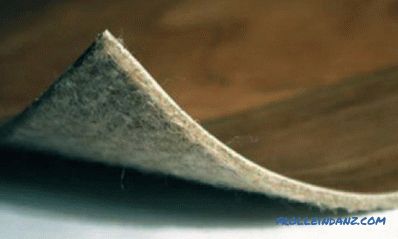

Basic

This is the name of linoleum, which has a heat insulating, woven or non-woven substrate. Such a material lies flat on any surface due to its elasticity.

Video: Popular types of linoleum produced in our time

Photos of various types of linoleum