No matter where the intended use of wood raw materials - in construction, in the manufacture of furniture or joinery blanks - its humidity will be the main indicator of the quality and durability of the finished product. Wood has a natural hygroscopic property, that is, the ability to absorb moisture well and just as quickly give it away with changes in temperature and humidity of the environment. As a result of these processes, there is a significant increase or decrease in the volumetric size of the material in different directions, leading to the complete failure of the structure or object. In order to understand how to dry wood, you need to know some rules that allow you to professionally carry out this process, and be able to determine the content of moisture in the tree.

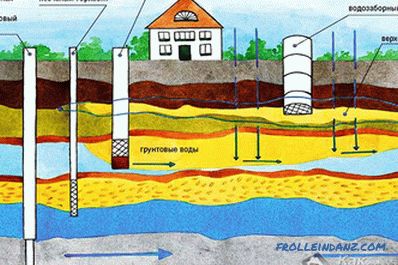

Scheme of wood drying in atmospheric conditions.

Determination of wood moisture

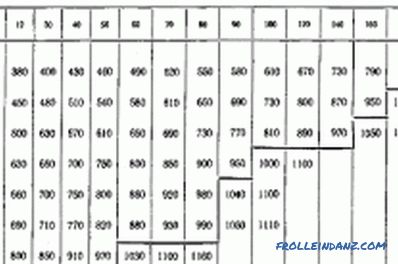

In the absence of a special device - an electro-moisture meter - the moisture content of wood is determined using a fairly simple method. A small piece is separated from the material and weighed. Then it is kept in a dryer at a temperature of about 100 ° C and weighed again. The difference between these indicators and is the percentage of water to the sample. When performing any technological operations in relation to wood, it must have a suitable moisture content.

Table for determining the moisture content of wood.

If this indicator is high, the probability of a quick failure of a future product is very high. Possible occurrence of fungal infections of the material, its rotting and deformation due to various climatic changes. Raw wood is poorly bonded, and due to subsequent drying, it can warp, crack, and form cracks. All these troubles can be avoided if we study how to dry wood, then competent drying of raw materials will be carried out in compliance with all the technologies of this process.

How to dry wood for different operating conditions

All wood species can be divided into three groups according to the properties to change the size during drying: slightly, moderately and strongly drying.

The larch and spruce practically do not change when dried, moderately lose pine, aspen, willow and poplar in volume. The wood of oak, elm, maple and beech belongs to the latter category, which also includes linden and alder. The most rapid evaporation of moisture occurs from the upper layers and the ends of the board. When drying raw wood, moisture at the same time leaves the pores from the surface, and its place is taken up by rising from the core through the capillaries tree sap.

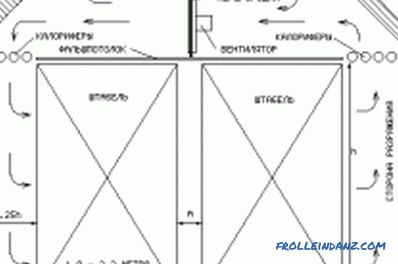

Scheme of drying wood in the chamber.

The humidity of wooden products, which will subsequently be used outdoors, should be in the range of 12–18%, and for indoor premises with a comfortable temperature, this figure drops to 8–10%. Therefore, it is necessary to dry wood, which will be operated in a heated room, in two stages: first in natural conditions, and then at room temperature. Drying wood under the influence of the atmosphere takes quite a long time. This period depends on the type of wood, its thickness and time of year. The use of this method can lead to the loss of material up to 75% of moisture, but coniferous and soft hardwood usually dries for about 2 years, and solid may require a longer period.

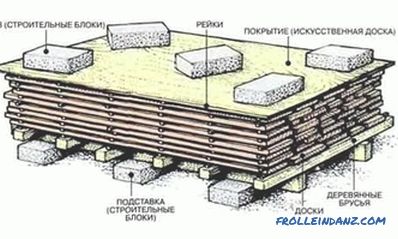

To dry wood in the open air, a pole is pre-laid, on which the workpieces are stacked with a small distance between them and the rows are fixed with hammered pegs. The upper layer is given a slight slope to ensure that rainwater rolls down, and is carefully covered with boards. Round logs before drying do not need to be removed from the bark so that they do not crack, for the same purpose, their ends can be treated with a solution of lime or table salt, which will additionally serve as protection from possible decay. Sawn timber is dried in the same way, but they must first be sorted and stacked according to the principle of uniformity, that is, the thickness of the boards and the tree species. The wood of valuable species in the process of drying is treated not only from the ends, but also on the sides, and for this purpose you can additionally use garden var or PVA glue.

Drying wood in a room

To dry wood in a room should be as far as possible from dirty and damp surfaces, which can be possessed by a dirt floor or concrete structures. It should be remembered that the tree will acquire the parameters of the environment, so the room should be dry and with an optimum air temperature of 15 ° C. In private homes, well ventilated attics are considered the best places for drying, and mezzanines can be used in apartments.If there is an urgent need, you can equip one of the rooms with air heaters, placing them along the walls, and constantly adjust the temperature for faster drying of the material. If you plan to manufacture furniture or joinery, you should not cut the workpiece before drying the wood - their size and shape can change significantly after shrinking.

Didn't find the answer in the article? More information on the topic:

-

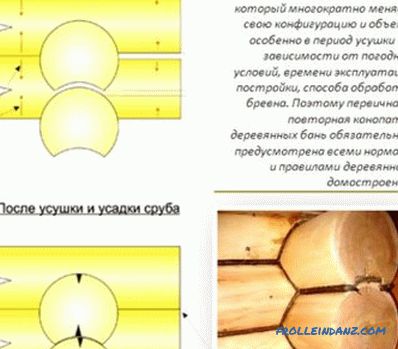

How should I properly caulk a bath?

Instructions on how to properly caulk a bath. A list of tools for the job, recommendations for choosing a compactor for a log house, as well as a description of two caulking methods.

-

The better to process the wood from moisture

How to treat wood from moisture. Useful tips and tricks, basic characteristics of impregnations and materials, design features, nuances. Advantages and disadvantages of impregnation.