A good well will provide water for the dacha, but its proper arrangement and warming is required. This becomes relevant in those areas where the comfort of everyday life depends on such structures.

It is easier to carry out a well-made well with your own hands at the stage where communications are laid. If the finished structure is insulated, it will have to be destroyed, which will require a lot of strength. Properly chosen material for insulation affects the quality of the functions performed by the well.

Natural materials

Use of natural materials

Use of natural materials

The use of scrap materials will significantly save you such as leaves, sawdust or straw. It is recommended to warm the well with these materials after the preparatory work. Do not forget that all natural materials are subject to decay, therefore they need protection.

Waterproofing materials

Glass wool

Glass wool

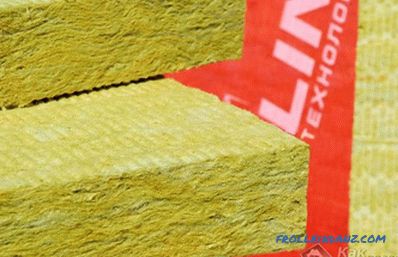

Glass wool and polystyrene are used to insulate the wells. . Basalt wool with penoizol is not without popularity. These materials are widely used in regions with cold winters.

The process of warming

We need to dig a deep trench around our well. The width of such a pit should be at least 1. 2-1. 4 meters, while its depth is about 2 meters or more. Now you need to make a formwork, which looks like a wooden box. Inside it lay the insulation in the form of leaves or expanded clay. It is recommended to paint the formwork itself with high-quality paint that will protect the wood from moisture.

For the box, you can take galvanized iron, which is wrapped with concrete rings. With this method of insulation you need to monitor the reliability of fixing the material. As in the previous version, the selected heater is poured into the formed voids. Warming the well must be done strictly following the advice of experts, otherwise the result will not meet the expectations:

- The integrity of the well will allow you to maintain the correct thickness of insulation, which must be at least 40 cm for any material.

- From the casing to the insulation layer, there should be a ventilation gap, which will play the role of a thermos, maintaining the temperature inside our structure at a certain level.

- The insulation layer must be at the level of soil freezing, but it must be prudent to lower it a few centimeters lower to provide some kind of reserve.

- It is recommended to fix them before casing warming.

Stages

Lid as a heater

Lid as a heater

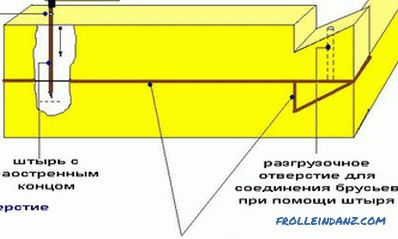

The casing is insulated first leaving the source. According to experts, it is best to initially wrap it with a mesh of plastic or metal, leaving a 5-6 cm gap. This will help create a kind of casing, which must be filled with leaves or sawdust. Only then can the pipe be wrapped with waterproofing material.

Even high-quality insulation will not allow to avoid the construction of a cover that will protect the structure from rain and snow. Its size should correspond to the diameter of the casing.

Heater

Heating cable

Heating cable

This method is more expensive but and its effectiveness is higher. Such heaters are mounted near or inside wells. The fiberglass insulation cable is tightly wound around the casing. All components of this design must be carefully insulated. Moreover, protection against precipitation must be of high quality.

If the cable is properly laid, the heater can also be installed inside the well. Equipment must have a certain capacity. For self-installation it will take a lot of knowledge and experience, so it is better to trust the professionals.

Alternative

Alternative design - caisson

Alternative design - caisson

An alternative option is installation of caisson design. In fact, this is a pipe inserted into the ground, the lower part being below the level of its freezing, and the upper part protruding to the surface.

The walls of this design are additionally insulated, and the upper part is covered with a lid, which will prevent rodents and other objects from getting inside. The main advantage of this method of insulation is reliable sealing.

The installation of the caisson structure must be carried out in compliance with the main requirement - a person must fit inside and carry out necessary troubleshooting procedures.

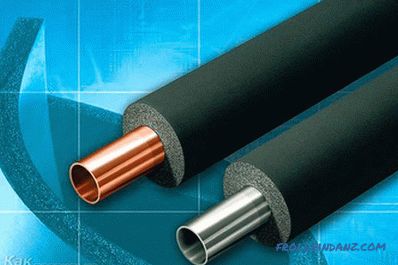

Insulation of pipes

Thermal insulation of pipes

Thermal insulation of pipes

The method of pipe insulation depends on from their styling. Under the ground, these products must be wrapped with mineral wool and top ruberoid. The pipes laid above the soil are insulated with mineral wool and construction foil.In regions with severe frosts, it is necessary to hide pipe products in special boxes, wrapping them with expanded polystyrene.

As you can see, it is easy to insulate a well and you can do it alone. Even in a harsh winter your building will have water, while your neighbors will not be able to get it from the well. Do not forget about the source shell, which will create an additional level of protection and block the path of garbage.

How did you solve the issue of warming a drinking well and pipes? What materials were used? Share your experience with our readers by leaving comments on the article.

Video

We recommend watching the video about the arrangement of the well and the work on weatherization of the water source.