Each owner of a private house or cottage can make a wooden gate with his own hands. Initially it is recommended to prepare a blueprint for a future design. Based on this, the amount of work to be done and the amount of materials needed are determined.

Before the construction of wooden gates, you need to determine their type and size.

Basic rules

Gates from a tree are presented in the form of a swing construction with 2 doors. Pine is used for their manufacture. This wood has a low weight and is resistant to environmental influences. You can make a wooden gate using the following materials:

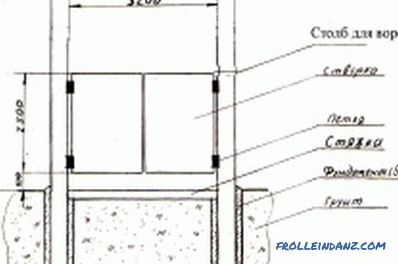

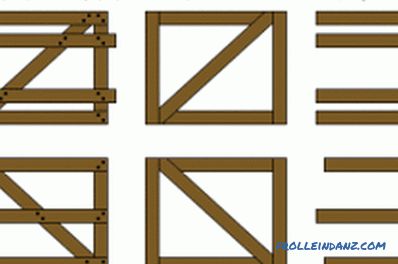

Wooden gate construction.

- bars;

- edged boards 25 mm thick and 100 mm wide;

- loops.

Of the tools you will need:

- a hammer;

- a hacksaw;

- a drill;

- a drill;

- paddle;

- tape measure;

- brush;

- self-tapping screws;

- sandpaper.

Doors with their own hands set on vertical supports. For the manufacture of the last elements used oak beams.

As for the size of the supports, their height corresponds to that of the gate, plus 1 m for penetration.

It should be noted that the deeper the support is installed, the more stable and stronger will be the wooden gates. This eliminates the possibility of skewing this design during its operation.

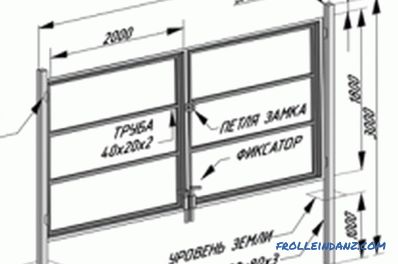

Gate scheme with basic dimensions.

The place where the support will be installed is cleared of debris. Then with a shovel digging pits, the diameter of which exceeds that of the supports by 10-20 cm. The bottom of each pit is tamped. Originally laid a cushion of rubble. Then the support is mounted. Verticality of such an installation will need to be checked using a plumb line. Before pouring the concrete, it will be necessary to process the corresponding part of the support with a special composition (liquid resin or bitumen mastic). This substance prevents rotting wood. The next step involves the preparation of concrete mix and fill holes. Subsequent work produced after complete drying of the composition.

Production technology

Double-leaf gates.

The gates are made of timber with their own hands. This raw material is cut into parts of appropriate sizes. For the production of the 1st sash gate will need 2 bars for the bottom, top, lintels and sides.

The surface of each piece of wood is made by hand with a plane and an antiseptic. It should be noted that the strength of the entire structure depends on the strength of the joints of the constituent elements. The frame is assembled by special fastenings - wooden dowels.

In the places of fixation, they make through holes into which the nogs are inserted. These fasteners are pre-treated with epoxy glue. To strengthen the mount, apply screws. In the central part of the frame there is a jumper made of timber. In the corners fix the stitches. These details are presented in the form of bars with a length of 300-400 mm. If the wooden gate has a height of 2 m, then the sides should not exceed 160-170 cm.

Cladding and installation

The next step involves the preparation of boards for covering. The wood is cut to size. Each side of the boards is processed by a plane. The wood is attached to the gate with self-tapping screws. The boards are placed close to each other or with a small step. The latest technology involves the use of a template, the length of which must coincide with the length of the material for plating. As for the thickness of the template, this parameter depends on the distance between the boards.

If the trim is installed, then you can trim the top of the boards. These places are cleaned with sandpaper. Similarly, make the 2nd gate leaf. The installation of this design provides for the fastening of the loop to the doors. Installation of wood screws-grouse is made after the manufacture of holes, the diameter of which is smaller than that of fasteners.

The wooden gate must be installed at a distance of 5 cm from the soil. In the closed state, the structure is fixed with latches, bolts and latches. Wooden gates should be painted in assembled form. The substance is applied to the tree in 2 layers.

Another method

Metal framework for the gate.

Wooden gates can be made from a metal frame. This technique is considered more practical, and it allows you to make a lightweight product. It should be noted that the metal frame significantly extends the operational process of the whole structure. High-quality plating will hide the frame, giving the gate an original appearance.

Wooden gates are installed on a metal frame with the following tools and materials:

- pipes;

- metal rods;

- bars;

- self-tapping screws;

- cement;

- sand.

Initially set up the supports. They can be made of metal pipes. From above the product is covered with a special primer. The height of the elements will be the height of the gate plus 1 m. Arrangement of holes and pillows is carried out in the same way as in the 1st case. The upper part of each support is closed with a cap. This will prevent moisture from entering. Wooden gates allow the use of steel caps as plugs.

Prepared parts are interconnected by welding. Diagonals of the resulting construction should have equal values. To wooden gates were presented in the form of a rigid product, apply rods. The wooden paneling is attached to the frame with the help of corners. They need to be welded at the top and bottom of the structure, while maintaining indent from the sides of 200-300 mm.

Holes are made in each corner. Bars fasten with bolts. Their length should coincide with the width of the leaf. On this timber attach boards for cladding screws. If this process is carried out without gaps, then you get a solid canvas. Otherwise, the pattern is applied. Before installation, the metal construction is covered with a special primer in 2 layers. Similarly, do with the 2nd flap. If necessary, you can make a wood gate.

Didn't find the answer in the article? More information on the topic: