Polycarbonate is one of the new building materials that appeared on the market about twenty years ago. This polymer from the family of thermosetting plastics looks very decorative and has good strength. Different types of polycarbonate are used in all areas of construction, both industrial and private. A wealth of colors and variety of sizes allow you to embody any idea.

Types of polycarbonate by sheet device

To begin with, this material can be solid or cellular in its internal structure. Accordingly, the leaf arrangement of the two species will differ. Consider what it is.

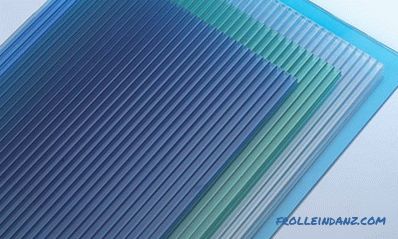

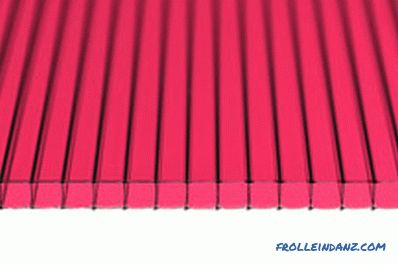

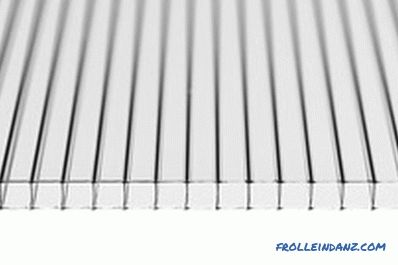

Polycarbonate of cellular type

Looking at the side of a cut sheet of cellular polycarbonate cut across, you can see a pattern resembling a honeycomb. It is formed by stiffeners mounted obliquely or straight. As a result, triangular or rectangular cells are obtained that contain air and that give special properties to this polycarbonate: sound insulating, thermal insulating, strength.

His sheets are issued with the following structure:

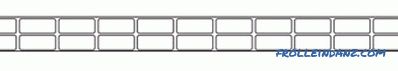

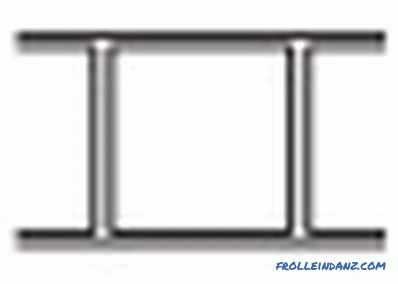

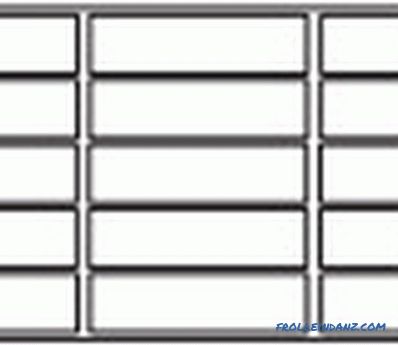

2H - double-layered panels with rectangular cells inside. With a thickness of 0.4 to 1 centimeter, stiffeners are regular partitions.

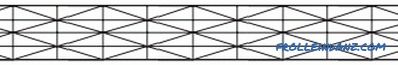

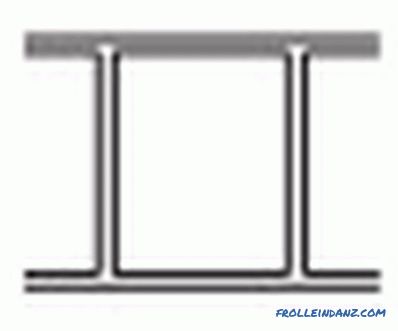

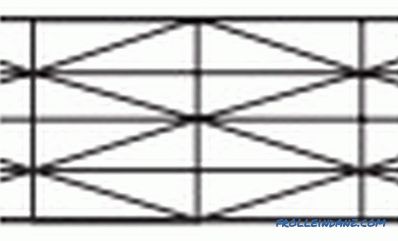

3X - three-layer sheets equipped with both straight and inclined (additional) stiffeners . The thickness of these ribs is set by the manufacturer.

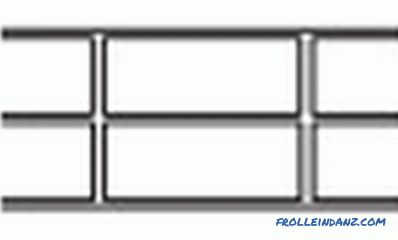

3H - three-layered sheets with a rectangular honeycomb structure, produced in a thickness of 6, 8, 10 mm.

5W - five-layer sheets with a rectangular honeycomb structure, as a rule, have a thickness of 16 - 20 mm.

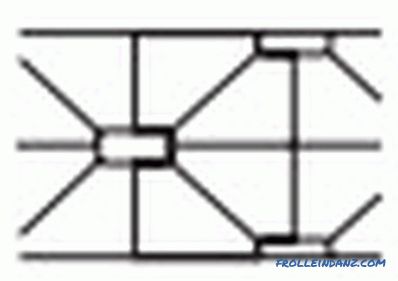

5X - five-layer sheets consisting of both straight and slanted ribs are 25 mm thick.

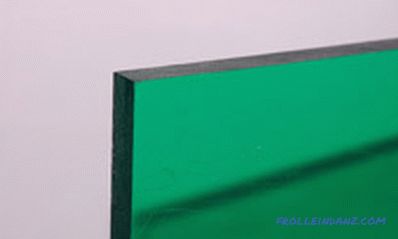

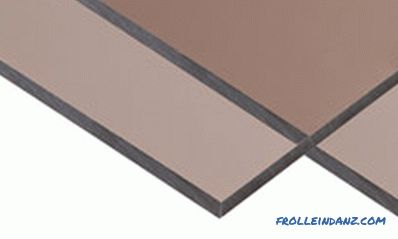

Polycarbonate of monolithic type

The material is in many ways similar to silicate glass. But it’s not so easy to break it (with a stone, for example), which is an undoubted advantage. Like the fact that scratching it is quite difficult. In the context of the sheets of such polycarbonate are solid array (usually transparent or translucent).

Monolithic polycarbonate is available in two versions:

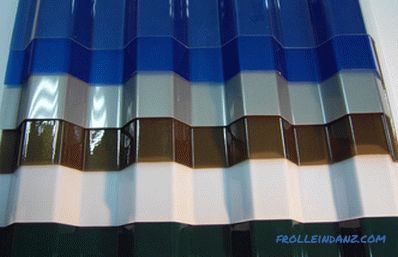

Straight panels (transparent or colored).

Profiled panels having the form of waves. They have increased strength and are well combined with roofing core materials (metal tile).

It should also be noted that polycarbonate of a monolithic type is produced by different grades - it is easier to choose the most suitable for a specific purpose.

Some of them:

- PC-5 is positioned as a material used for medical needs.

- PK-6 - a polymer with high transparency. Used in lighting and optics (for the manufacture of parts of devices).

- PK-M-1 - a material with minimal friction.

- PK-M-2 is the only material on the globe that is so good at resisting cracks and not afraid of fire.

- PC-LT-18th (previously called PC-4) is a black material with high thermal stability.

- PC-LST-30 (formerly called PC-NKS and PC-LSV-30) is a polymer whose filler is silicon or quartz glass.

- PK-TS-16-OD - this marking shows that polycarbonate is not afraid of flame and extremely high temperatures. Use it where fire safety is important.

- PC-010 (formerly PC-3 or PC-LT-12) is a plastic whose viscosity is very low.

- PC-003 and PC-005 (formerly PC-1) - on the contrary, materials with rather high viscosity.

- PC-007 (produced instead of PC-LT-10 and PC-2) is a material with an average viscosity value.

Dimensions of polycarbonate sheets

It is worth remembering that the standard size of a polycarbonate sheet, like the structure, depends on its type.

Dimensions of cellular polycarbonate

In cellular polycarbonate, the width of all sheets is the same - 210 centimeters, except for sheets having a thickness of more than 2 cm, they can be made 2.5 cm thick. And the length can be either 12 meters , or 6. A six-meter-thick sheet 0.4 cm thick weighs about 10 kilograms, with a density of polycarbonate about 800 grams per square meter. The thickness of the material can be from 0.5 to 2.5 centimeters.

| Specifications | Ed.measurements | Parameters | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Sheet thickness | mm | 4 | 6 | 8 | 10 | 16 | 16 | 20 | 25 |

| Number of layers ( walls) | 2H | 2H | 2H | 2H | 3X | 3H | 6H | 5X | |

| Cell structure |

|

|

|

|

|

|

|

| |

| Distance between stiffeners | mm | 6 | 6 | 10 5 | 10.5 | 25 | 16 | 20 | 20 |

| Sheet width | m | 2.1 | 1.2 | ||||||

| Minimum allowable bending radius | m | 0.7 | 0.9 | 1.2 | 1.5 | 2, 4 | 2.4 | 3.0 | Not recommended |

| Specific weight of the sheet | kg / m 2 | 0.8 | 1.3 | 1.5 | 1.7 | 2.5 | 2.8 | 3.1 | 3.4 |

| Panel Length | mm | 6000 and 12000 (deviation from the nominal size of 1.5 mm for transparent sheets and 3 mm for color are allowed) |

* Depending on the manufacturer, these parameters may vary in one direction or another.

Dimensions of monolithic polycarbonate

The length of one standard sheet of monolithic polycarbonate is 305 cm and width is 205 cm. The thickness of the products is usually from 0.2 to 0.6 cm. Under the order it is possible to purchase thicker sheets (from 0.8 to 1.2 centimeters).

Types of polycarbonate by color

And again we will separately consider cellular and solid materials. Note that in both cases, dyeing is performed throughout the volume, therefore, over time, colored products do not lose their saturation of shades. For color sheets will have to pay - five percent, not more.

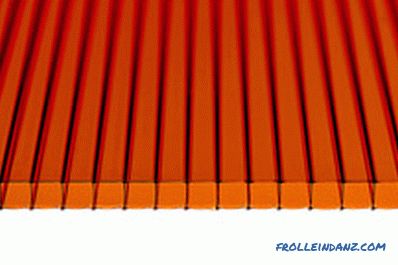

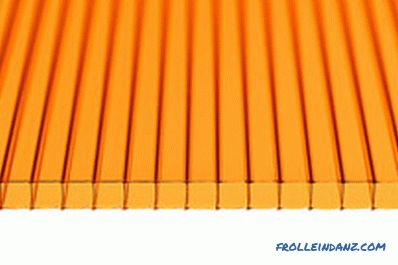

Cellular polycarbonate

There are the following color variations:

Bronze

Orange

Garnet

Transparent

Milky

Monolithic sheets

As in the previous version, completely transparent, bronze and milky sheets are produced (the latter are matte). There is a pure white (opal) variation. In the color present:

Transparent

Bronze

Black

Red

Milky

Green