Lightweight, durable and relatively inexpensive profiled (otherwise, professional sheet) has received recognition from many developers. From this material in two accounts you can build a garage, kiosk or warehouse. Using various types of sheeting, you can revet the walls, build a roof, fence or partition.

The types of sheeting by profile are their characteristics and characteristics

It is worth noting at once that one common detail is inherent in all types of sheeting. This refers to the coating, which can be either more simple (galvanized) or more decorative and durable - polymer. Otherwise, each type of profile has its own shape, depth, width. Due to this, stiffness and durability of corrugated board are changing, which allows it to be widely used in modern construction. Next we look at each type of profile and its technical characteristics.

* Attention! The given sizes of the general and working width of a leaf can differ depending on the producer of a professional flooring.

Profile C8

This is a sheet with a wavy surface. It has a slightly lower strength than the profiles discussed below. It can be simply galvanized or coated with polymer coatings. Most often available in brown (chocolate), blue, white, cherry and dark green colors. With a sufficiently large angle of inclination of the roof material is used for the roof. It is also used as a facing material for walls and in the construction of fences.

Spheres of use of the C8 profile in construction:

- Roof installation in the presence of a continuous batten;

- Construction element during the construction of temporary and other quickly under construction constructions;

- Steel roof - a painted galvanized corrugated board is used;

- Frame constructions - a corrugated sheeting is used;

- Panel and enclosing structures - a painted profiled sheet with a galvanized coating is used;

- External walls and wall constructions in the construction of small structures (garages, household appliances pavilions);

- Steel fences - a galvanized sheet coated with polymer is used;

- Sheeting of walls with a decorative effect - a painted galvanized steel sheet is used;

- Wall covering material and wall construction constructions;

- As an element of prefabricated sandwich panels;

- As an element of composite sandwich structures of floors, walls, partitions (fire-fighting, internal);

- Fences and enclosing structures - a corrugated profiled sheet with a decorative protective coating is used.

Characteristics of profiled C8:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.5; 0.55; 0.65; 0.7 mm. |

| Sheet length | 0.5 to 12 m. |

| Sheet width total | 1200 mm |

| Working sheet width | 1150 mm. |

| Profile height | 8 mm. |

| Profile pitch | 115 mm. |

| Weight per square meter: | - |

| 0.5 mm. | 4.5 kg. |

| 0.7 mm. | 6.17 kg. |

|

Example of designation: Profiled C8-1150-0.5

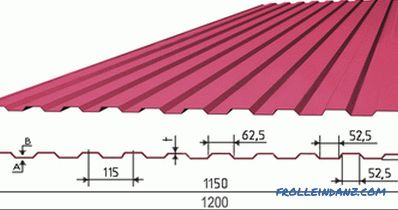

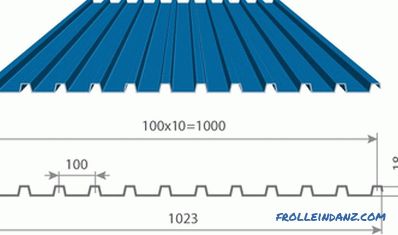

Profile C10

This is a trapezoid sheet. This material also has a reduced strength. Coverage and colors are the same as in C8. This type of corrugated board is used for the arrangement of the roof with a sufficiently large angle of inclination, the construction of prefabricated structures, fences, outbuildings and buildings. It is used for the manufacture of bearing parts, wall sandwich panels, as well as partitions that protect buildings from fire.

Spheres of use of the C10 profile in construction:

- Roof construction with a maximum pitch of 0.8 meters;

- Construction element during the construction of temporary and other rapidly building steel structures;

- Steel roofing - galvanized corrugated flooring with paint and varnish coating is used;

- In frame structures;

- External walls and wall construction structures for the construction of small structures (garages, household premises, trade pavilions);

- Steel fences - galvanized sheet coated with polymer is used;

- Sheeting of walls with a decorative effect - painted or galvanized steel sheet is used;

- Facing material walls and wall construction structures;

- As an element of prefabricated sandwich panels;

- As an element of composite sandwich structures of floors, walls, partitions (fireproof, internal);

- Fences and fencing structures - corrugated profiled sheet with decorative protective coating is used.

Characteristics of C10:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.4; 0.45; 0.5; 0.6; 0.7; 0.8 mm. |

| Sheet length | 0.5 to 12 m. |

| Sheet width total | 1150 mm |

| Working sheet width | 1100 mm. |

| Profile height | 10 mm. |

| Profile pitch | 115 mm. |

| Weight per square meter: | - |

| 0.5 mm. | 4.6 kg. |

| 0.6 mm. | 5.83 kg. |

| 0.7 mm. | 6.33 kg. |

| 0.8 mm. | 7.64 kg. |

| |

Example of Designation : Profiled C10-1100-0,7

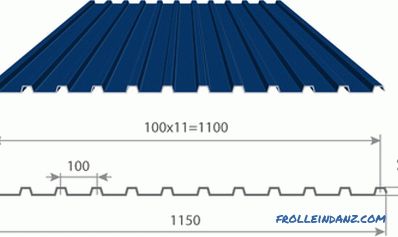

C18 Profile

This is a sheet with a ribbed or wavy surface. In the latter case, the material is designated as: C18 (wave). Due to its small thickness, it is easily processed, cut and drilled. Colors, types of polymer coatings are similar to the above profiles. Due to its decorativeness it is very good for making fences and fences. Suitable for roofs with a pitch of not more than 40 centimeters.

Spheres of use of a professional flooring C18 in construction:

- Material for facing walls, ceilings;

- Different partitions;

- Fences, panel structures, fences;

- Roofing, the roof slope must be with a slope not exceeding or equal to 25є,

- Roof covering with a maximum pitch of 0.4 meters.

Characteristics of the C18 Profile:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.4; 0.45; 0.5; 0.6; 0.7; 0.8 mm |

| Sheet length | 0.5 to 12 m. |

| Sheet width total | 1023 mm. |

| Working sheet width | 1000 mm. |

| Profile height | 18 mm. |

| Weight per square meter: | - |

| 0.5 mm. | 5.18 kg. |

| 0.6 mm. | 5.57 kg. |

| 0.7 mm. | 7.13 kg. |

| 0.8 mm. | 8.11 kg. |

|

Example of designation: C18-1000-0.5

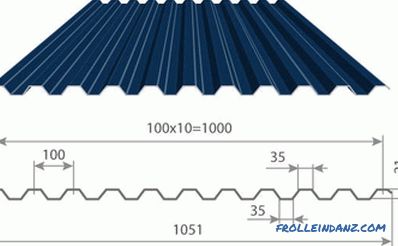

professional flooringProfile C21

This is a corrugated sheet, the surface of which is ribbed, trapezoidal in shape. The following polymers protect against corrosion: polyester, pural, polyurethane, prism. It is used for roofing with a crate with a step up to 80 centimeters. In addition, like the previous profiles, it is used for construction and cladding of buildings, structures, fences and outbuildings. It has greater strength and versatility compared to previous profiles.

Spheres of use of the C21 profile in construction:

- Roof construction, maximum sheathing step 0.8 meters;

- Construction element during the construction of temporary and other fast-building steel structures;

- Steel roofing — a painted corrugated flooring with galvanized coating is used; 24>

- External walls and wall constructions during the construction of small structures (garages, utility rooms, tons orgy pavilions);

- Steel fences - galvanized sheet coated with polymer is used;

- Sheeting of walls with a decorative effect - painted galvanized steel sheet is used;

- Material for wall and wall cladding construction structures;

- Element of prefabricated sandwich panels;

- Element of composite sandwich structures of floors, walls, partitions (fireproof, internal);

- Steel fences and other similar barriers - used professional sheet with a decorative protective coating.

Characteristics of the C21 profile:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.4; 0.45; 0.5; 0.55; 0.6; 0.65; 0.7; 0.8 mm |

| Sheet length | 0.5 to 12 m. |

| Sheet width total | 1051 mm. |

| Working sheet width | 1000 mm. |

| Profile height | 21 mm. |

| Profile pitch | 100 mm. |

| Weight per square meter: | - |

| 0.5 mm. | 5.14 kg. |

| 0.7 mm. | 7.13 kg. |

| 0.8 mm. | 8.11 kg. |

|

Example of designation: C21-1000-0.7 professional flooring

Profile C44

This is a very durable galvanized sheet with a fairly high trapezoid profile. It can be covered with a layer of one of the polymers. Due to the increased rigidity, this material is quite possible to use even for a roof with a rare crate - up to 2 meters. Since it can withstand very large loads, it is well suited for the manufacture of bearing elements.Hangars, fences, garages and cabins, sandwich panels from it are easy and durable.

Areas of use of corrugated C-44 in construction:

- Fencing structures, metal fences;

- Wall covering material, ventilated facades buildings;

- Roofing for flat and pitched roofs.

Characteristics of the C44 profile:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.5; 0.55; 0.6; 0.65; 0.7; 0.8; 0.9 mm. |

| Sheet length | 0.5 to 13.5 m. |

| Sheet width total | 1047 mm. |

| Working sheet width | 1000 mm. |

| Profile height | 44 mm |

| Trapezoid step | 20 cm. |

| Weight per square meter: | - |

| 0.5 mm. | 5.09 kg. |

| 0.7 mm. | 6.97 kg. |

| 0.8 mm. | 7.92 kg. |

| 0.9 mm. | 8.78 kg. |

|

Example of designation: C44-1000-0.8 professional flooring

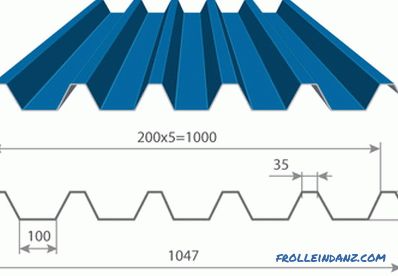

HC35 profile

This is a sheet with an additional ribbed surface. Like the previous types of materials, can have a polymer coating. The roof of this profile is extremely durable and airtight. In this case, the step of its crate up to 1.5 meters is allowed. For wall, bearing and panel structures, this material is also great.

Spheres of use of the HC35 profile in construction:

- Roof installation, maximum sheathing step 1.5 meters;

- Construction element during the construction of temporary and other rapidly building steel structures;

- Steel roofing - a galvanized corrugated sheet is applied with a paint and varnish coating;

- Frame constructions - a corrugated steel sheet is used; galvanized coating;

- Exterior walls and wall structures during construction are small constructions (garages, domestic premises, trade pavilions);

- Steel fences - galvanized sheet coated with polymer is used;

- Sheeting of walls with a decorative effect - painted galvanized steel sheet;

- Material for cladding walls and wall constructions;

- Element of prefabricated sandwich panels;

- Element of composite sandwich constructions of floors, walls, partitions (fireproof, internal);

- Steel fences and other similar fences - a professional sheet is applied with a decorative protective covering is

HC35 profile specifications:

| Parameters | Minimum values |

|---|---|

| Sheet thickness | 0.5; 0.55; 0.6; 0.65; 0.7; 0.8; 0.9 mm. |

| Sheet length | 0.5 to 12 m. |

| Sheet width total | 1060 |

| Working sheet width | 1000 |

| Profile height | 35 mm. |

| Trapezoid step | 200 mm |

| Weight per square meter: | - |

| 0.5 mm. | 5.09 kg. |

| 0.7 mm. | 6.98 kg. |

| 0.8 mm. | 7.93 kg. |

| 0.9 mm. | 8.77 kg. |

|

Example of designation: HC35-1000-0,7 professional flooring

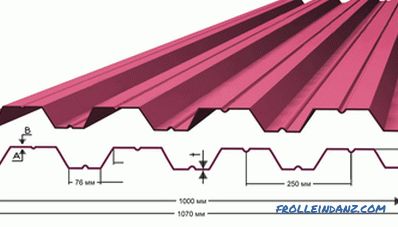

HC44 profile

Like the previous type, this sheet has additional stiffeners, which add strength to structures made from it. The profile has the shape of a trapezoid, can withstand solid loads, allows you to build a durable roof that will not leak. Permissible lathing pitch is 3 meters. Naturally, this professional sheet can be used for all other construction works described a little earlier.

Spheres of use of the NS44 profile in construction:

- Roofing or flooring, the maximum pitch of the batten is 3 meters;

- Sheet reinforcement of reinforced concrete floors with

- Interfloor composite floor slabs;

- Stiffening diaphragm in buildings with a metal frame (profiled material is taken into account);

- Sheet metal formwork (non-removable);

- The structural element in the construction of temporary and other rapidly constructed steel structures;

- Steel roofing - a galvanized corrugated sheet is applied with a paint and varnish coating;

- Frame constructions - steel sheets are used;

- Panel and enclosing structures - a painted professional sheet with a galvanized coating is used; 23> External walls and wall constructions during the construction of small structures (garages, utility rooms, trade pavilions);

- Steel fences and other similar barriers - galvanized steel sheet or galvanized with paint coating is used.

Characteristics of the HC44 profile:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.4; 0.5; 0.7; 0.8 |

| Sheet length | 0.5 to 12 m. |

| Sheet width total | 1070 mm. |

| Working sheet width | 1000 mm. |

| Profile height | 44 mm. |

| Profile pitch | 250 mm. |

| Weight per square meter: | |

| 0.4 mm. | 4.4 kg |

| 0.5 mm. | 5.4 kg. |

| 0.7 mm. | 7.4 kg |

| 0.8 mm. | 8.4 kg. |

|

Example of designation: HC44-1000-0.8 profiled flooring

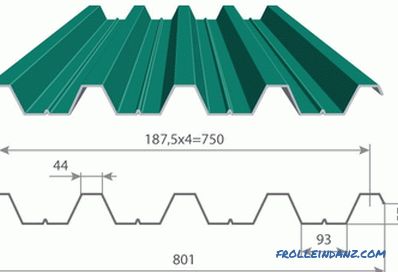

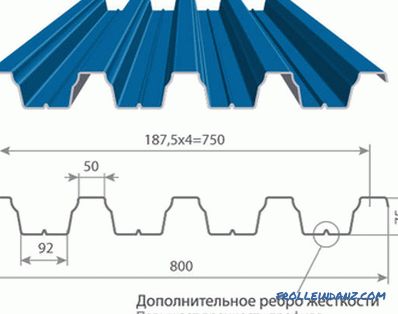

Profile H57

This is a corrugated trapezoid sheet with a high profile. A distinctive feature is the presence of additional gutters on the corrugation. Due to this, a wider layer of insulation can be placed under the profiled flooring, which increases the strength of the erected structures. This profile is used for roofs with a step of batten up to 3 meters, as well as for panel metal fences. Also, load-bearing elements, permanent formwork, sheet reinforcement for floors made of concrete and steel, composite slabs between floors, rigid partitions are made from it.

Spheres of use of the H57 profile in construction:

- Roofing or flooring, the maximum pitch of the batten is 3 meters;

- Sheet reinforcement of reinforced concrete floors with

- Interfloor composite floor slabs;

- Stiffening diaphragm in buildings with a metal frame (profiled material is taken into account);

- Sheet formwork (non-removable);

- The construction element in the construction of temporary and other fast-built metal structures;

- Steel new roof - galvanized corrugated sheet with a paint and varnish coating is used;

- Metal sheet formwork (non-removable);

- Frame constructions - steel sheet sheets are used;

- Panel boarding and enclosing structures - painted profiled is used sheet with galvanized coating;

- Exterior walls and wall construction structures for the construction of small structures (garages, utility rooms, trade pavilions);

- Steel fences and other similar barriers - galvanized steel sheet or galvanized steel nan seniem refinishing.

Characteristics of the H57 profile:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.6; 0.7; 0.8; 0.9 mm. |

| Sheet length | 0.5 to 14 m. |

| Sheet width total | 801 mm |

| Working sheet width | 750 mm. |

| Profile height | 57 mm. |

| Trapezoid step | 187.5 mm. |

| Weight per square meter: | - |

| 0.6 mm. | 7.04 kg. |

| 0.7 mm. | 8.14 kg. |

| 0.8 mm. | 9.19 kg. |

|

Example of notation : Profiled sheeting H57-750-0.8

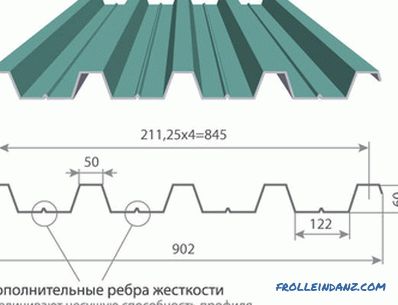

Profile H60

This trapezoidal profile sheet has almost the same characteristics as the previous one, differing from it in greater thickness and increased height of the corrugations. Accordingly, it has greater rigidity and strength.

Spheres of use of the H60 profile in construction:

- Roofing or flooring, the maximum pitch of the batten is 3 meters;

- Sheet reinforcement of reinforced concrete floors with

- Interfloor composite floor slabs;

- Stiffening diaphragm in buildings with a metal frame (profiled material is taken into account);

- Sheet formwork (non-removable);

- The construction element in the construction of temporary and other fast-built metal structures;

- Steel new roof - galvanized corrugated sheet with a paint and varnish coating is used;

- Metal sheet formwork (non-removable);

- Frame constructions - steel sheet sheets are used;

- Panel boarding and enclosing structures - painted profiled is used sheet with

- Galvanized coating;

- External walls and wall constructions in the construction of small structures (garages, utility rooms, trade pavilions);

- Steel fences and other similar barriers - used galvanized steel sheet or galvanized with paint coating.

Characteristics of the H60 profile:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.7; 0.8; 0.9; 1.0 mm. |

| Sheet length | 0.5 to 14.5 m. |

| Sheet width total | 902 mm. |

| Working sheet width | 845 mm. |

| Profile height | 60 mm. |

| Trapezoid step | 211.25 mm. |

| Weight per square meter: | - |

| 0.7 mm. | 8.10 kg. |

| 0.8 mm. | 9.21 kg. |

| 0.9 mm. | 10.21 kg. |

| 1.0 mm. | 11.32 kg. |

|

Example of designation: Profiled sheeting H60-845-0.8

Profile H75

One of the most powerful types of corrugated board. It has the highest strength characteristics. This is largely due to the presence of additional ribs. The leaf surface is trapezoidal, the profile height is maximum. Elements of the roof, walls or bearing parts of the building, which require special strength, are produced from this material. Specific areas of application are similar to the two previous types of profile. The step of crates for the roof of this material can reach 4.5 meters.

Spheres of use of the H75 profile in construction:

- Roofing or flooring, the maximum step of the batten is 4.5 meters;

- Sheet reinforcement of reinforced concrete

- Interfloor composite floor slabs;

- Stiffening diaphragm in buildings with a metal frame (profiled sheet material is taken into account;

- Sheet formwork (non-removable);

- The structural element in the construction of temporary and other fast-built metal structures;

- Steel Naya roof - galvanized corrugated sheet with a paint and varnish coating;

- Metal sheet formwork (non-removable);

- Frame constructions - steel sheets used;

- Panel boarding and enclosing structures - painted painted sheet with galvanized coating;

- Exterior walls and wall construction structures for the construction of small structures (garages, utility rooms, trade pavilions);

- Steel fences and other similar barriers - galvanized steel sheet or galvanized steel on Eseniya refinishing.

Characteristics of the H75 profile:

| Parameters | Values |

|---|---|

| Sheet thickness | 0.65; 0.7; 0.8; 0.9; 1.0 mm. |

| Sheet length | 0.5 to 14.5 m. |

| Sheet width total | 800 mm. |

| Working sheet width | 750 mm. |

| Profile height | 75 mm. |

| Trapezoid step | 187.5 mm. |

| Weight per square meter: | |

| 0.7 mm. | 9.15 kg. |

| 0.8 mm. | 10.6 kg. |

| 0.9 mm. | 11.53 kg. |

| 1.0 mm. | 12.87 kg. |

|

Example of designation: Profiled flooring H75-750-0.8

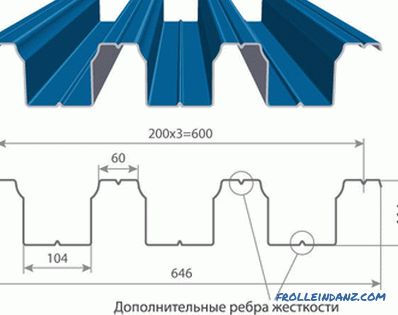

Profile H114- 600

This type of profile differs from the previous one by the presence of one more work piece of rigidity, which gives it even greater strength. This sheeting is able to withstand very high loads without deflection and can be installed both in horizontal and in vertical positions.

Areas of use of the H114 profile in construction:

- Roofing or flooring, the maximum step of the batten is 6 meters;

- Sheet reinforcement of reinforced concrete floors with

- Interfloor composite floor slabs;

- Stiffening diaphragm in buildings with a metal frame (profiled material is taken into account);

- As sheet formwork (non-removable);

- The structural element in the construction of temporary and other rapidly built metal structures d;

- Steel roofing - galvanized corrugated sheet with a paint and varnish coating is used;

- Metal sheet formwork (non-removable);

- Frame construction - steel profiled sheets are used;

- Panel and fencing structures - a painted profiled sheet with galvanized coating is used;

- Exterior walls and wall constructions in the construction of small structures (garages, utility rooms, trade pavilions);

- Steel fences and other similar barriers - a galvanized professional sheet or zinc is used bath with paint coating.

Characteristics of the H114-600 profile:

| Parameters | Minimum values |

|---|---|

| Sheet thickness | 0.8; 0.9; 1.0 mm. |

| Sheet length | 0.5 to 13 m |

| Sheet width total | 646 mm . |

| Working sheet width | 600 mm. |

| Profile height | 114 mm. |

| Trapezoid step | 200 mm. |

| Weight per square meter: | - |

| 0.8 mm | 12.4 kg . |

| 0.9 mm | 13.8 kg. |

| 1.0 mm | 15.3 kg. |

|

Example of designation: Sheet H114-600-0.8

Types of profiled sheets depending on the application

Roof decking

This type of material is used for the construction of light, airtight and durable roofs. Its main distinguishing feature is sufficient rigidity and ability to withstand heavy loads. Attractive design and beautiful colors make this professional sheet quite suitable for facing works, the construction of decorative (but at the same time reliable) fences and other fences that do not deteriorate due to the weather. As an example, you can call the following types of corrugated roofing: HC44, HC35.

Pros of a profiled sheet:

- low weight per square meter;

- low cost;

- large service life, high reliability;

- quick and easy installation;

- beautiful exterior design.

Apply this material when there is a need:

- Build a new roof that can withstand heavy loads;

- repair an old roof;

- to revet the facade of the house;

- to build a fence or fence;

- to build a decorative structure.

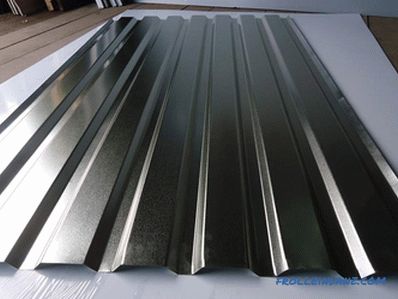

Carrier profiled

This material is used when elements of buildings and structures that are exposed to significant loads are mounted. Bearing external walls, strong roofs, sturdier floors - this is the area of use of this profiled sheet. It is easy to recognize the bearing profiled sheet - its profile is quite high, and there are special grooves on the corrugation. Examples of brands: H57, H60, H75 and H114.

The advantages of the base profiled sheet:

- It is possible to make sheets of any size on request;

- reasonable price;

- long service life (it can be from 40 to 60 years);

- installation is simple and convenient, takes place in a short time.

Apply this material when there is a need:

- Build the load-bearing elements of the house (for example, external walls);

- securely repair the roof, the load on which is large;

- mount the new roof, assuming that it will accumulate a lot of snow and wind and rain loads will also be noticeable;

- to trim the facade of the building, as well as its walls or ceilings;

- to build a solid fence.

Wall sheeting

It is used not only for the construction of walls (external and internal). It is also good to make fences surrounding private houses from such a profiled sheet. It is inexpensive, it protects against corrosion thoroughly, therefore it is very popular with professional builders. It, as a rule, has a rectangular or trapezoidal profile, can be simply galvanized, or with a polymeric coating. Examples of brands: С8, С10, С18, С21, С44. It should be noted that the most popular types of sheeting for walls and fences are C8 and C21.

Advantages of wall profiled sheet:

- The walls of it are much easier than of reinforced concrete;

- it is easy to drill holes and cut this material so installation is simple;

- low cost.

Apply this material when there is a need:

- Cladding or facing works;

- carrying out facade works;

- mounting the bearing elements;

- performing work on the roof (building a new roof or repairing the old one);

- manufacturing decorative metal structures.

Types of sheeting, depending on the type of protective coating

All coatings used to protect sheeting can be divided into two large groups - this is zinc or aluzinc coating and coating with polymeric compounds.

Galvanization - the simplest basic protection

The professional sheet of any type is made of cold-rolled steel with a thickness of 0.5 to 1 millimeter. To protect the metal from corrosion, apply various coatings. The basis of the vast majority of these coatings is the familiar hot-dip galvanizing. This means that the steel sheet is dipped into molten zinc, seeking to create a protective layer with a thickness of 25 to 30 microns. It turns out galvanized profiled - finished material, which is the cheapest of all. It is used for repair, construction and restoration work.

The aluminum zinc coating protects against aggressive substances

Instead of galvanizing, steel can be coated with more resistant aluminum zinc, which is also called galvium. It consists of three components: zinc (43.4 percent), aluminum (55 percent) and silicon (1.6 percent). The last element is needed for a strong bond between the first two metals. Profiled with aluminum zinc protection will be good for the roof of a house on a busy highway, on the sea coast or in an industrial area.The aluminum which is a part of a covering will save a roof from various "chemistry" or the sea evaporations which are contained in air.

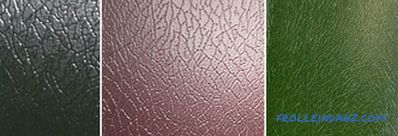

Plastisol - will save from mechanical damage

For greater strength, the galvanized sheet is primed and then coated with an organic polymer. The strongest of these polymers is a plastisol coating with a thickness of 175 to 200 microns. Such a solid layer will help you withstand blows with honor, as well as avoid scratches. Also, this plastic and durable material is not exposed to aggressive media. But he also has disadvantages: fading with time, instability to ultraviolet radiation and temperature changes.

The appearance of the plastisol coating.

Polyester - popular, decorative, reliable

According to statistics, about 85 percent of roofing materials are covered with polyester. After all, it is perfectly resistant to corrosion, and at the same time it is not afraid of frost and heat, and also does not lose its bright color for a long time. Very effectively looking, decorating buildings, a professional flooring with a matte polyester coating.

Decking coated with polymeric protective coating Polyester.

Pural - a beautiful and durable novelty

To be more precise, this material, developed recently by Ruukki®, is called PURAL® matt. Its main component is polyurethane. A professional leaf covered with pural need not be afraid of sunlight, chemical aggression or corrosion. From it you can build not only the roof of the building, but also beautifully revet its facade.

Texture of the polymer coating Pural.

PVDF coating - the best in color fastness

This material (otherwise, PVF2, or polydifluorionad) is particularly resistant to adverse weather events. Corrosion is not able to damage it, and juicy color has not changed at all for many years. Therefore, such a profiled most often revet the facades of houses. This is especially successful if the color scheme is important.

Whatever composition the polymer protection would have for different types of sheeting, it should be fixed. To do this, apply a thin glossy film of paintwork. It consists of several layers, reaching a thickness of 40 to 300 microns. This reduces the chance of corrosion to zero, and also has a decorative function. After a few years, this layer should be updated - it is quite easy.