Drainage of sewage is one of the problems that every owner of a country house will face. Septic tanks are one of the most popular solutions to this problem - their design is adapted for cleaning and phased removal of liquid sewage, leaving only solid particles to be pumped out. It is possible to determine which septic tank is better to give, based on the type of soil at the installation site, the frequency of residence and the financial possibilities of the owners.

Material of cumulative containers

The design of any septic tank involves the use of one or more containers located underground. They can be made independently or purchased ready-made, the main requirement is that a sufficient level of tightness is observed, and the surface is resistant to aggressive chemical elements.

Capacity of reinforced concrete rings

It is one of the most durable and resistant to various influences of materials. After the installation of such a container, it is possible not to fear that within a few years the structure will be eroded by groundwater and it will collapse. The truth must be borne in mind that in addition to the purchase and delivery, you will most likely also have to pay for mounting the rings in the pit. Also, besides the rings themselves, it will be necessary to purchase reinforced concrete circles for the bottom of the tank and the top, into which the ventilation hatch is mounted.

Plastic storage tanks

One of the most reliable materials in terms of tightness and resistance to acids, alkalis, and other aggressive components of groundwater and sewage. Of all the materials suitable for creating septic tanks, plastic is the lightest and allows manual installation, with the involvement of a minimum number of assistants. With care, it should be used only in areas with moving loose soils.

Monolithic reinforced concrete structure

It is made according to the principle of foundation: it is poured directly on the installation site using removable formwork, in which the cement-sand mixture hardens. For greater strength, reinforcement is mandatory applied, and for resistance to groundwater, a waterproofing layer is applied to the outer walls after removing the formwork.

Metal tanks

Metal containers for septic tanks are also being manufactured at present. The strength of these septic tanks can be called their strength. The most pronounced disadvantage is corrosion, which in aggressive environments leads to the rapid destruction of such containers. The first to be destroyed are the joints. Before use, all metal containers are treated with anti-corrosion agents, but you need to understand that all these agents will protect the container for only a while, after which active metal corrosion will begin.

Types of septic tanks and their structural differences

Each of the types of septic tanks consists of several stages of wastewater treatment. In the original designs, only mechanical cleaning was used, the quality of which did not exceed 70%, and with the addition of biological filters, the purity of the output water rose to 98%, which allows its use for technical purposes.

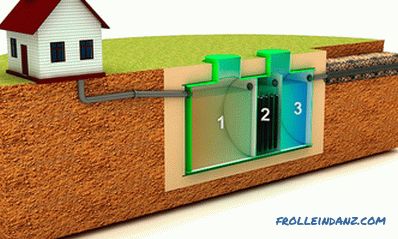

A septic tank with a filtration well

This is the easiest way to arrange sewage treatment on the principle of a septic tank, but compared to a standard cesspool, it requires certain financial investments for the purchase of ready storage tanks. You can also build them yourself from reinforced concrete rings. In fact, the whole structure consists of several sealed containers underground, interconnected by means of overflow pipes. The last tank is a filtration well with a sandy bottom strewn with rubble.

The principle of operation of such a septic tank is to sequentially filter out heavy elements and fats from drains. First, the entire contents of the sewage system enters the first tank, at the bottom of which the largest and heaviest fractions settle, and water with lighter particles flows into the second tank when the first tank is filled, where the process repeats. As a result, the most purified liquid enters the last well and goes into the ground through a cushion of rubble and sand.

Septic tank with a filtration field

Improved system of the previous method. The use of this technology makes it possible to increase the efficiency of the treatment plant, as a result of which the water flowing to the earth has less impact on the ecosystem, and the septic tank will be cleaned less frequently.

Structurally, the whole system consists of three main elements:

1 Sump . Two or three tanks interconnected by overflow pipes, each subsequent of them must be at a level below the supply.

2 Distribution Well .It performs a double function: at the same time it is the next tank for settling small particles, plus it collects water for transfer to the next stage of cleaning.

3 Filter field . It consists of a cushion of sand and gravel (rubble) with perforated pipes laid on it, which are directly connected to the distribution well. Sand-gravel pad performs the role of the last stage of cleaning - its thickness is at least 1 meter.

The principle of operation is to sequentially filter out heavy particles. The initial rough cleaning is carried out in overflow accumulation tanks, in which the dirt is divided into particles heavier than water and fats floating above. As a result, clarified water enters the distribution well, in which there are light insoluble suspensions. They enter the filtration field and are held up by a sand-gravel pad.

The whole system can be further improved by making an additional well behind the filtration field, into which water is collected that has not gone into the filtration layer. From the well, it is pumped out into a separately equipped drainage channel

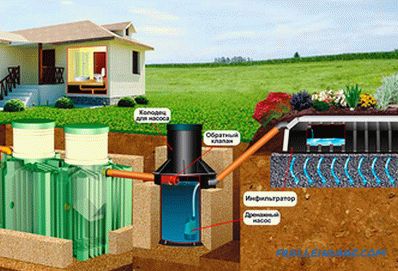

. Septic tank with infiltrator

By its principle of operation and efficiency, this system is equal to the filtration fields, but it significantly benefits in terms of the occupied area. The infiltrator itself is a long plastic container, shaped like an inverted trough with openings on the sides in the form of blinds. On the one hand, water is supplied to the infiltrator for cleaning, on the other hand there is a ventilation outlet. From above, a hatch is usually arranged through which the infiltrator is cleaned of accumulated debris. In terms of efficiency, one infiltration tank with a capacity of 400-500 liters replaces about 40 m² of filtration fields.

There are two most common constructions of such a septic tank: standard and with an intermediate well. The first of them is completely non-volatile with the movement of water by gravity, consists of tanks of the settling tank, after which the infiltrator is mounted, which is installed on a pillow of sand and rubble.

The second scheme looks exactly the same, but between the septic tank and the infiltrator there is an additional well, inside which is installed a drainage pump controlled by a water level sensor. Water is supplied to the well through a pipe with a check valve. Due to the presence of the pump, this filtration system is volatile.

The principle of operation of the standard scheme. Drainage from sewage enters the septic tank for primary cleaning from particles heavier than water. After filling the last tank, the water is fed into the infiltrator, and after it enters the sand-gravel pad for final cleaning.

The scheme with an intermediate well, in fact, works in exactly the same way, but has an increased resistance to the so-called salvo discharges, when for any reason a large amount of water is discharged into the filter installation at a time and the infiltrator does not have time to bring it to filtering sand and crushed stone pillow.

Septic tank with biofilter

This filter installation is actually done independently, but for a number of reasons it is better to buy a ready-made one, in which all the necessary parameters are calculated, and all the components and filter elements are in one case.

This system has three main compartments separated from each other by walls, perforated in certain places for the overflow of liquid:

1 Septic tank primary cleaning . Consists of a settling chamber.

2 Anaerobic bioreactor of type . Depending on the model, it is a conventional container - hollow or with strips of synthetic fabrics placed on the walls that are not subject to rotting. This creates conditions for anaerobic bacteria.

3 Accumulation tank for purified water . In some cases, an additional mechanical filter is mounted here.

The principle of operation is based on the sequential flow of effluent from the chamber into the chamber by gravity. In the first compartment, consisting of two parts, sewage is separated into particles heavier than water, which settle to the bottom of the chamber, liquid and a film of fats, which are formed on the surface. Secondary (coarse) cleaning of the septic tank separates particles not dissolved in it from the water, for which cloth or similar filters are used.

Anaerobic bacteria that live in an oxygen-free environment are pinched inside the second tank and decompose the organic compounds remaining in the water during their life.

The third tank is used to collect purified water and then take it to the ground or use it for technical needs. When using additional mechanical cleaning water is driven through a layer of expanded clay or sandstone.

Station of deep biological treatment

In essence, this system completely repeats the entire path that the wastewater passes through when released into the environment. As a result of the station operation, all sewage effluents are decomposed into process water with a degree of purification of about 98% and sludge, which can be used as fertilizer or processed into biofuel. The difference with natural cleaning is that the whole process is completely controlled - the same sludge is not collected on the banks of water bodies, but is used for its intended purpose.

The design of a deep bio-cleaning station is not fundamentally complex and can be made independently if desired, although it is likely that the size of the home-made device will be manufactured in an industrial environment.

It consists of several compartments:

1 Reception chamber . Here are drains from the sewer.

2 Chamber of the secondary clarifier .

3 Aerotential . Capacity in which constant air injection is organized.

4 Bioreactor . A hollow tank with a special float loaded into it, where aerobic bacteria are populated.

5 Final clarifier .

This is the simplest scheme — in some cases, systems with two aerotanks and a large number of intermediate sedimentation tanks are used.

The principle of operation of a deep cleaning station becomes clear if we consider the operation of each chamber separately.

Drainage from sewage flows into the chamber of the first clarifier. Here, the bulk of the sediment is separated, which is subject to primary decomposition, due to the effects of anaerobic bacteria living on the bottom. Part of the mass will remain in the chamber in the form of sludge, and the other will eventually fall into the next compartment.

Oxygen can partially flow into the secondary chamber, so the aerobic and anaerobic bacteria simultaneously act on the effluent inside it.

After the secondary clarifier is filled, the drains enter the aeration tank - there they are actively saturated with air, which is specifically injected into the chamber with a compressor. As a result, a mixture is formed from the liquid of the sludge particles floating in it and air bubbles. In the next compartment of its most convenient to submit airlift - it starts when the tank is filled.

In the next chamber, plastic floats float on partially clarified drains, on which aerobic microorganisms live. They also process the bulk of organic matter, finally decomposing them into fertilizer sludge and clean process water.

The last compartment serves to store purified water, at the same time working as a final settling tank.

Choosing a septic tank depending on operating conditions and soil type

Installing a septic tank is not a cheap pleasure, therefore, before choosing a particular design, it is necessary to take into account their performance characteristics, seasonal demand and soil characteristics in which they will be installed.

Which septic tanks are best used for giving for year-round living

If the financial issue is not the main one, then for a house with permanent residence, the best option would be a deep biological treatment station. Despite the high initial price, it has a rather short payback period - it is better to have a septic tank for giving without waste pumping. Of course, the waste will be when using any cleaning system, but in this case you can remove it yourself and use it as fertilizer.

The main advantage of this system is its ability to use in any conditions, since the result of the work is clean water and environmentally friendly sludge. The disadvantages include the possibility of the death of bacteria, if you do not use the sewage system for about two weeks, and the intolerance of chlorine and similar active chemical compounds by microorganisms.

All other cleaning systems will be more expensive to operate, which over time will override the initial price, or harm the environment, as they cannot provide an adequate level of cleaning.

Which septic tank is better for giving with non-permanent residence

In this case, everything depends on the period of time during which sewage is not actively used at the dacha. If the owners come for the whole summer, then you can consider the option with a biological treatment system or with a biofilter, but before you arrive you will have to spend about 15 y. E. To purchase a new batch of bacteria.

In any other case, you can use other types of septic tanks, focusing more on the nature of the soil in which it will be installed. Also it should be taken into account that the construction of a septic tank with an infiltrator and an intermediate well allows it to withstand significant salvo discharges of wastewater.

Which septic tanks are better to use on sandy soils

The most affordable option is to use a septic tank with a filtration well. Its advantages include simplicity of design, complete non-volatility and slow occupancy of containers. If space is available, a septic tank can be used with a filtration box or an infiltration device. All of these septic tanks are designed for the removal of treated water directly into the ground and if it is sandy, then this is the best option for their operation.

Which septic tanks are suitable for use on clay soils

In addition to universal biological treatment systems, on soils with poor water absorption, an optimal solution would be to use a septic tank with an infiltrator and an intermediate well. This choice is due to the ability of the septic tank to prevent the reverse flow of water, if it did not have time to soak into the ground. When installing such a system, it is necessary to remember about its volatility - for the operation of the pump need electricity.

In case of extreme necessity, a septic tank with a filtration well can be used on clay soils, but at the same time it will have to be cleaned more often than the estimated time. The use of a septic tank with a filtration field is not recommended, as there is a possibility of a reverse outflow in the tanks of the sumps.

Which septic tanks should be used with high groundwater levels

High groundwater levels often lead to the same problems as low fluid absorbency soils - when the filtration elements are filled, the water will go back to septic tank sumps. This makes it impossible to use structures in which the drains pass from section to section by gravity.

There are only two options that are most suitable in this case:

- a septic tank with an infiltrator with an intermediate well, which has a non-return valve, and an electric pump supplies water to the infiltrator ;

- any of the systems of biological treatment - they all operate on electricity, and their containers are sealed, and do not allow ground water to enter the system.

Comparison of septic tanks on the basic parameters

In order to better understand which septic tank to give is better, in each specific case, compare them with each other on the basic characteristics.

The cost of a septic tank and its equipment

There is a simple rule - the simpler, the cheaper. The least money will have to be spent on an ordinary septic tank with a filtration well, and the arrangement of a system with a filtration field or an infiltrator will cost more. The highest price is from biological treatment systems, especially if you purchase a device made in an industrial environment, but if used correctly, the costs will quickly pay off.

Installation complexity

The purchase of biological treatment systems, which are often performed by manufacturers in the same package or several of equal size and connected in series, are clearly leading here. For them, you just need to dig a single hole and install the entire system into it.

It is a little harder to install a septic tank with a filtration well, for which you need to dig a few holes, and at the bottom of the latter you can also lay a pillow of sand and rubble.

Septic tanks with a filtration field or an infiltrator can be considered the most laborious to install. For each of them, it is necessary to remove the soil from a sufficiently large area, lay sand and gravel (crushed stone) into the resulting pit, install filtering elements and back up all of the earth.

Installation of the infiltrator.

Installation of a filtration field.

Frequency of maintenance

Any septic tank needs to be cleaned much less than a cesspool - the more perfect the design, the less reason to call a vacuum truck:

Septic tank with filtration Well . The overflow tanks of the septic tanks themselves are cleaned about once every six months, and rubble and sand at the bottom of the well should be changed every 5-7 years.

A septic tank with a filtration field or an infiltration device . Since the purified water is discharged over a large area, it is enough to replace the pillow once every 10 years. The time of silting of the septic tanks completely depends on their size and intensity of use of the sewage system.

Biological or deep cleaning stations . The accumulated sludge is sufficient to extract once every six months, while all operations can be carried out manually.

The degree of sewage treatment

According to the level of cleaning, all septic tanks are divided into devices for mechanical action on drains and combined - mechanical and biological. In the first case, the cleaning level will be about 70% - such water cannot be used even for irrigation, and only lawn grass can be planted over the filtration field or infiltration plant. In the second case, the degree of wastewater treatment reaches 95-98% - these are normal parameters for process water, which can be used for irrigation or other technical needs.

System Volatility

Of the systems presented, only two are volatile: a septic tank with an infiltrator with an intermediate well and a deep biological cleaning station. In the first case, an electric drainage pump is used, and in the second, compressors plus aerlift pumps. Depending on the power of the entire device, power consumption can range from 1.5 to 30 kW per day.