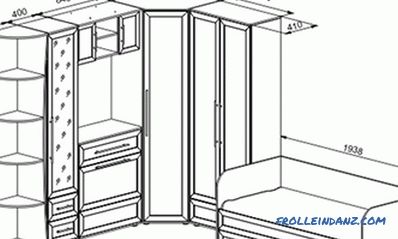

Many home craftsmen try to bring a piece of their soul into the house by means of their own making furniture. In order to make a corner cabinet with your own hands, it will take a lot of effort, although financially this event will not cost so much. Externally, such a cabinet has the shape of a square with a truncated angle.

Corner Cabinet Layout.

Preparatory work

At the very beginning, you need to decide on the material from which the entire structure will be made. Optimally fit only 2 options.

The furniture panel is quite simple and flexible in work, and it is also absolutely natural. When choosing, you can immediately get acquainted with the type of wood used and select the thickness. It is desirable to use the material without knots, since it is more reliable, and it is much easier to work. There are 2 minuses in the material: a very high cost and increased time at work. That high cost scares many people.

Laminated chipboard is much easier to work with, but making a complex pattern or forming a pattern based on partial cutting will not work by hand, because this requires additional equipment. The color spectrum is huge, but the material is always visible (there is no possibility to form a wood pattern, even with special desire). The ability to choose the density and thickness also give their advantages, although the framework is more rigid than that of a furniture board. It is from this material it will be more convenient to make a corner cabinet with your own hands.

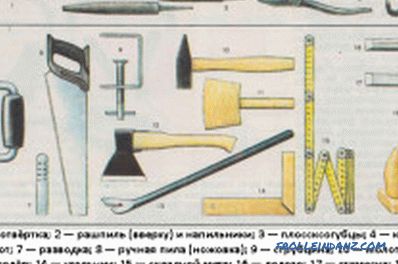

Tools for making a corner cabinet.

It is advisable to purchase all the internal fittings not only of high quality, but also from the same material and from the same manufacturer. Such a move will allow you to create a corner cabinet that is not at all distinguishable from a factory one in quality, and it will be almost impossible to point out its home production when considered.

Files for jigsaws are tearing from one side strongly or from two sides little by little. In this case, it is better to use those that are torn from 2 sides, since the top can still be closed with a piping.

Required tools and materials for work:

- jigsaw;

- screwdrivers;

- chipboard;

- furniture screws;

- aluminum screws;

- rubber pads (5 pcs.);

- piping for laminated chipboard;

- iron;

- fittings.

Main working activity

After the preparation of the drawing has been completely completed, you can proceed to its production.

The most convenient way is to make a corner cabinet with an equivalent spread, since there is not 1 chance to do something wrong. To start, the cut is made:

- 2 segments 900 * 2610 mm;

- 2 segments 500 * 2610 mm;

- 1 segment 540 * 2610 mm;

- 5 segments 380 * 450 mm;

- 1 segment 450 * 2200 mm;

- 3 segments with 5 corners so that they fit exactly inside the walls.

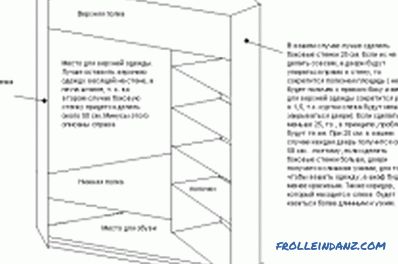

The corner wardrobe assembly scheme.

When cutting, it is impossible to make an error of even 2 mm, since this may break stability or give an uneven joint. And after all the cuts are formed, you need to start connecting the segments together.

To begin with, 2 corner walls are joined together. Furniture screws are used for this, for which holes are initially made with a drill in 40 cm increments, after which they are fixed. Or you can use the internal aluminum corners, which are grabbed with the same step. In the latter case, you need to carefully monitor the length of the screws, so that it does not exceed 3/4 of the thickness of the chipboard. The method is selected initially, after which it will not change.

Similarly, segments of 500 * 2610 mm are docked to them. At this stage, the outlines of the future corner cabinet are already visible, but right now one should be as careful as possible, since the frame at this stage is at maximum risk.

Now you need to mount the bottom part from below, and at a height of 2-4 mm above the base, in order to achieve maximum stability. Similarly, the top cover is mounted, only it is as close as possible to the top edge (1-2 mm can be left). Now the box already has good strength reserves, but still it is not worth it to once again expose to loads.

An indent of 380 mm is made from any of the front plates and a vertical bar of 450 * 2200 mm is fixed. It is fixed not only to the rear, but also to the bottom. There is a gap above, which it is immediately desirable to close with the remaining 5-coal slab, after which everything is fixed mutually. It is at this stage that the rigidity is brought to almost maximum, since the main protective elements are already mounted.

The simplest thing is to install the shelves and pipes. The pipe is mounted in a larger compartment with the greatest care. There should not be sorry for screws, because sometimes the load will be truly huge.But the shelves can be made in any interesting way, and most often for them only 2 guides are installed, and the plates themselves are not fixed by anything, which is very convenient if you need to quickly facilitate the cabinet or complete careful dismantling.

Only at the very last stage hinges are mounted and doors are mounted on them.

Additional aspects

After the work on making the cabinet is completed, you need to complete the image with the help of Kant. The piping is fixed to all open edges of the particle board with the help of an ordinary household iron (the polymers melt at its base, after which the wood is coupled).

After the corner cabinet is fully assembled, you can make side open shelves for it, hang a mirror on the door, and also modify the design as your soul desires.

The design is quite strong, which will withstand even very serious loads.

Didn't find the answer in the article? More information on the topic:

-

How to make floors in a wooden house

You can make wooden floors as well as other materials for this. If bricks were used to organize the foundation, the beams are placed immediately behind the basement floor.

-

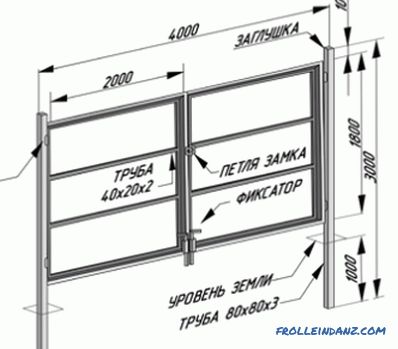

Making your own wooden door

Making a wooden gate with your own hands. Tools and materials necessary for the manufacture of wood gates. Sheathing and installation of wooden gates on a metal frame.