The construction of a frame house with your own hands is a completely feasible task. It is only necessary to understand the sequence in which the installation of the main elements is carried out, and you will be able to self-pour the foundation, build the skeleton and complete the structure of all the other elements. First, the sequence of home construction with your own hands as a whole will be considered, and then each stage separately.

The layout of the frame house.

Step-by-step instructions for building a frame house with your own hands

First, prepare the tools and materials that will allow you to install the frame house. You will need the following:

Figure 1. Schematic of a frame house with an attic.

- a large hammer and a smaller tool;

- several chisels of a different size;

- electric planers;

- a large nail puller and a smaller tool;

- jigsaw;

- electric disc saw;

- electric drill and drill set;

- construction level;

- plumb bob;

- several brushes of different sizes;

- screwdriver set;

- scaffolding;

- ladder;

- marker;

- concrete for foundation construction (you can do it yourself or buy a ready-made solution);

- fittings of different sections;

- waterproofing material (ruberoid is usually used);

- board of bearing walls (to arrange this part of the structure, you will need a board of 400x15x5 mm);

- boards for internal partitions (400x10x5 mm products are enough);

- OSB plates (plates with a thickness of 2.2 cm are traditionally used);

- heat-insulating material (foam plastic can be used mineral wool);

- polyethylene film for waterproofing structures;

- drywall for walls inside at rooms;

- wall paneling for the exterior of the structure (siding is also suitable);

- roofing material (experts recommend using metal roofing for the roof of a frame house, but if you wish, you can choose your choice for other materials );

- pipes, wires and other elements for a communications device (think in advance about the layout of your future frame house and buy materials in accordance with it);

- leveling compounds;

- antiseptic agents ;

- paintwork compositions.

The frame house itself can be erected in one of two ways, namely:

- Installation can be made from ready-made factory elements.

- Installation is carried out directly at the construction site, and the assembly and fastening of all elements will also be carried out independently.

Figure 2. Drawing the wall of a frame house.

In order to fully build a frame house with your own hands, it is better to consider the second option. First, prepare the project documentation and drawings. All the nuances, the order of mounting and mounting of various elements, dimensions and other important points should be foreseen in advance, so that later there would be no problems with fitting materials, etc. There are many typical projects. For example, it is possible to take as a basis the scheme of a frame house (Fig. 1). There are the main attachment points and interfaces. If you wish, you can order an individual project in a specialized company. The project should contain the drawings of the base of the frame house, plans for each floor, floors and roofing systems, as well as facades and cuts.

Under the project the foundation is made. Installation of a frame house is most often performed on the basis of the column type. Above the individual pillars are connected by a grillage into a single structure of high rigidity. For the device of such a foundation is not necessary to invite professionals. You only need to find one or two assistants. At this stage, it is imperative to check the horizontal surface of the grillage with the help of the construction level.

The fastening of the bottom trim is performed in the sequence:

- Waterproofing is laid on the ready foundation in the form of roofing felt.

- After that, the installation of the lower trimming bar is performed. In the corners, fastening is done with anchors or nails.

Figure 3. The technology of building a frame house with your own hands.

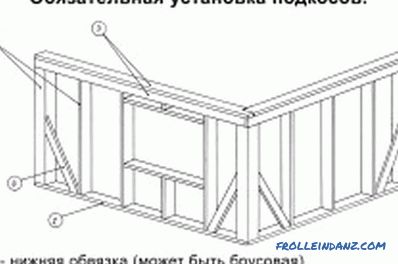

It is important to check the horizontal position of the timber. Its attachment must be strictly horizontal. Also checked the angles and diagonals. The fastening of the timber to the base of the frame house is carried out with anchor bolts. The distance between attachment points should be no more than 100 cm. The diagonals, angles and horizontal position of the beam are checked again.

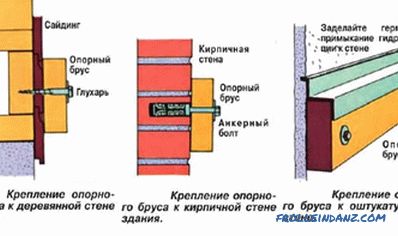

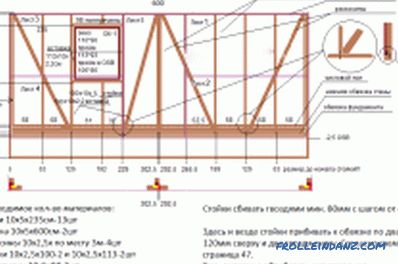

Next, the vertical uprights of the frame will be mounted. Work begins with corner elements. To make it easier, you can see how the mount looks (Fig. 2).Racks are fastened to the lower strapping bars. To do this, use reinforced corners of steel. See how the attachment points should be arranged (fig. 3).

It is necessary to make a temporary mount racks. So they will not stagger. Racks are fastened on one side diagonally using the board. Remember the door and window openings. In these places, the rack mount will be made at a distance different from other sections of the wall.

The installation of the top trim bar can be done using steel corners. Carefully check the horizontal and vertical mounting of all elements of this part of the frame house.

Next, each rack is fixed with fixed braces. Use a bar of relative small section. Look at the attachment points at this stage (Fig. 4). The installation and mounting of ceiling beams. Steel corners are also used. Created truss structure and obreshetka. The selected roofing is being laid. Outside the frame house is sheathed with plywood. You can use DSP or OSB. The vapor barrier is fastened. This is done with a construction stapler. In the future, the crate will be nailed and siding mounted on it.

Figure 4. Schematic design of the roof of a frame house.

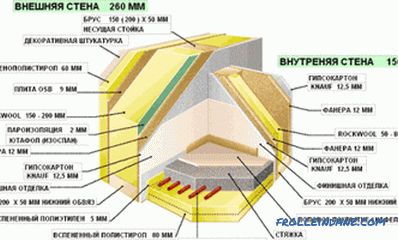

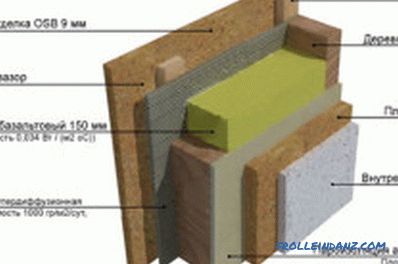

The space between the racks must be tightly filled with insulating material. It must be closed with a vapor barrier film. To attach it to the frame posts, use a stapler. Inside, the walls of the house are sheathed with plywood or OSB.

This is what the overall construction of a frame house looks like. However, this general information is not enough. Therefore, it is necessary to consider each stage separately.

Arrangement of the foundation for a frame house

As a rule, frame houses have 1-2 floors. Experts do not recommend to make a frame house above 2 floors. And the second floor is better to do mansard.

Most often, as already noted, a columnar foundation is erected for the construction of a frame house. You can use a tape base, as well as a prefabricated structure of concrete blocks. Belt systems require the use of durable reinforcement to create additional strength and rigidity. In the case of column systems, the required rigidity is ensured by a monolithic grillage. When erecting a precast base, a strong and reliable fastening is used to increase rigidity. It must be attached across the bottom trim.

Guide to the construction of the frame of the house

Floor plan of the frame house.

In the process of building a frame house, frame structures made of metal and wood are used. Metal frames increase the cost of a house by an average of 30-40 percent. Therefore, they are not as popular as wood frames. But at the construction of the metal is much less weight, which saves money on the foundation. In the case of wood, the most suitable material is oak. If there is no money for an oak, high quality timber from other species will do. Its cross section must be at least 150 mm². In the corners, the tongue and groove connection is used. It is necessary to adjust closely. Clearances are prohibited.

Professional builders categorically do not recommend the use of metal fasteners, as this material intensifies the processes of rotting wood. Therefore, whenever possible, screws and nails should be discarded. Rotting will make the connection weaker. In such conditions, the frame house will slowly but surely loosen. To ensure a reliable, durable and safe connection for the building, wooden dowels are suitable.

Thermal insulation material is most conveniently mounted in wall gaps. But in order for the structure to not lose its rigidity, it is necessary to loosen the frame with braces. If this is not done, under the influence of external loads over time there will be distortions, which will lead to further destruction. In accordance with the construction technology of a frame house, everything must be done taking into account the creation of 3 braces. They are made of the same material as the frame racks.

From the outside, the frame is lined with boards. It is best that the skin is not horizontal, but inclined by 30-40 °. To do this, you can use 6 cm thick grooved boards or clapboard. It is important to take into account the fact that the wood that you use for the construction of a frame house during the first 12-18 months may decrease or increase in volume. Therefore, it is not necessary to completely nail the cladding boards. Otherwise, in a year and a half, the skin can be deformed.

Arrangement of the floor and walls of the frame house

Scheme of the assembly of the walls of the frame house.

Installation of the structure begins with the laying of high-quality timber around the perimeter of the walls.Use a timber section of 15x15 cm. Before mounting the bursa, lay the roofing felt. Wood itself must be treated with an antiseptic composition. Installation is carried out using anchor bolts. Try to set the angles as accurately as possible. Use the building level to test. The maximum allowable misalignment is 1 cm.

The same materials should be used to construct the supporting structures of the walls and the floor of the frame house. If the materials are different, then their expansion coefficients will also differ. This can lead to the fact that over time, the house simply skewed. For the device of a rough floor use not cut off board. This is the most budget and quite acceptable option. First, the installation of lags. Between them fit insulation material. Top floorboards are arranged. After completing the creation of the floor proceed to the construction of walls.

Before starting to build walls, find a flat and dry platform for their collection. Otherwise, the wall will warp. The frame is assembled from identical vertical boards. If possible, you need to choose boards of such length that would correspond to the height of the premises of your future frame house.

Diagram of the structure of the wall of a frame house with insulation.

High ceilings are expensive materials. However, it is better not to do them below 2.4 m either. Otherwise, pressure will be felt in the room causing psychological discomfort. During the construction phase of the walls, you can think about saving on building materials by installing slanting ceilings. Such ceilings will have the same bevel angle as the slope of the roof slope. Thanks to this, you can create a comfortable attic room, install the right windows there and provide a more interesting and cozy result.

Calculate wall sections based on the maximum allowable and expected loads on the floor of the house. Beams are installed at a distance of 300, 400 and 600 mm. Select the width of the boards in accordance with the selected covering material.

How to sheathe the walls?

Device for the floor of a frame house.

Cladding is most often performed with siding. If you choose it, you need to maintain a distance of 20-30 cm. If a chipboard, pseudo-log or block house is used, you can increase the distance to 40-50 cm.

Siding is the most practical durable and easy to use cladding material. You do not have to paint it, open varnish. Do not even have to wash it regularly. The only drawback, and even then subjective, is the unnaturalness of such a finish.

If the frame house is made in factory conditions, then, as a rule, sandwich panels are used. From an economic point of view, this is the most profitable option.

Panels of such a plan weigh little, which makes it possible to reduce the load on the foundation of the frame house and, on the whole, to make its construction easier. In addition, sandwich panels have low thermal conductivity. This moment allows you to optimally solve the issues of thermal insulation of the frame house.

Installation of windows and installation of the roof

Due attention must be paid to the installation of windows. According to technology, the area of windows should be equal to 18% of the total area of the wall with a window opening. So the number and size of openings are selected individually. As for the double-glazed windows, single glazing is enough for seasonal use. If the frame house will be used throughout the year, you need to buy double-glazed windows with 2 or even 3 glasses. Select the required number taking into account the climatic features of your region.

And the last stage of the construction of the frame house construction is the arrangement of the roof. The roof can be covered with a variety of materials. Experts recommend the use of natural tile. It is best combined with wood. You can give a choice in favor of any other material that you like by its appearance, appearance or price. Good luck!