In the life of every motorist garage is not the last place. As for a woman, cleanliness in the house is important, and for a man, order in his garage is just necessary. The permanent attributes of this place are various cabinets, shelves and, of course, a large table.

When assembling the workbench, you need to take into account that the table surface must be thick enough so that it may not break when striking.

The table, like the rest of the furniture itself, can be made independently. The simplest solution would be to make a table from wood into the garage with your own hands.

Required tools and materials

The following tools may be needed:

- any piece of writing on wood;

- wood saw;

- tape measure;

- screwdriver and drill;

- level;

- gloves, plastic glasses and other security features.

I must say that other tools may be needed.

You will need the following materials:

- wood glue;

- wood;

- nails, bolts, and screws on wood.

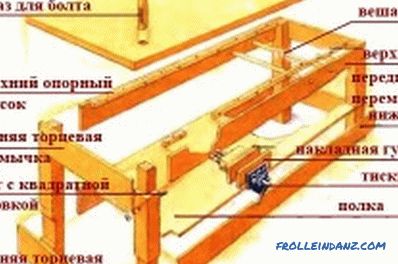

Workbench device.

As for wood, we can talk about such materials as:

- 2 boards with dimensions of 0.9 * 0.1 m and 2.5 cm thick ;

- 4 boards with dimensions of 1.7 * 0.1 m and 2.5 cm thick;

- 17 boards with dimensions of 1 * 0.1 m and 2.5 cm thick ;

- 2 boards with dimensions of 1.6 * 0.1 m and 2.5 cm thick;

- 4 beams with dimensions of 0.75 * 0.1 m and 5 cm thick .

It should be noted that if the table is going to be used as a storage place for any spare parts and tools, it is better to choose boards as thicker as the legs, for example, 75 * 10 * 10 cm

The same must be said about the length of the boards and, soo accordingly, the table itself.

Stages of self-assembly

The whole process can be divided into the following stages:

- Assembling the countertop frame.

- His gain.

- Fastening the boards to the frame.

- Installation of the legs.

Immediately you should decide what the table will be: collapsible or non-collapsible.

The only difference between them is that they are used as fasteners for individual elements.

If you plan to make the table collapsible, then you need to use bolts and nuts, if not folding, then screws and nails.

So, direct assembly begins with the fact that boards and bars of the required size are cut from the source material. Then they are all soaked with special antiseptic compounds. Since the table will be used in the garage, its elements need to be soaked with a fire retardant, a compound that protects the wood from open fire.

Only after this can the frame be assembled. First of all, boards of 1.7 * 0.1 m are placed on the edge at a distance of 90 cm between their outer edges.

Build a workbench.

After that, two more such boards are placed in the middle between the first two at regular intervals.

On the side, two boards of 0.9 * 0.1 m are nailed to them - these are the end strips. They serve for additional fastening of all bearing levels among themselves.

Then it is necessary to fasten to the extreme bearing boards one by one with dimensions of 1.6 * 0.1 m. These elements will serve as reinforcement of the rigidity of the whole structure.

After this step is done, 5 cm from the edge on each side will remain. This is enough to secure the legs. However, if a material with a greater thickness is chosen in their capacity, then the distance should be left larger.

After the frame has been manufactured and strengthened, the trimming should be started. Worktop boards are mounted across the load-bearing elements. A total of 17 such elements with a width of 10 cm are needed.

I must immediately say that the tabletop itself must be wider than the frame, so the boards are taken not 0.9 m, but exactly 1 cm. It is allowed to use and even longer. In addition, instead of 17 you can take 18 boards: this will help to hide the frame also from the ends.

At the end, the legs will remain attached. As already mentioned, this can be done with bolts or screws.

If bolts are used as fasteners, proceed as follows: first, drill holes of the desired diameter, and then tighten the bolts. It is necessary to use rubber gaskets on the side of the bolt and on the side of the nut. This is necessary so that there are no traces left on the attachment points.

Tips for making the table

As you can see, it’s not as difficult to assemble the simplest table for your garage as it seems at first glance. But to keep it clean is a bit more difficult task.

In order to prolong the life of the table and keep it in its original form, all its individual wooden elements are varnished. It is much easier to remove any dirt from the surface than from a pure tree.

Another important point is the question of the ease of use of such furniture.These are only approximate sizes. For the most part this concerns the height of the legs. They should be made to their height.

It should be noted that the legs themselves can be placed not inside the frame, but inside it. Fasten them in such a case, it is necessary to carry the outer boards and end slats.

In addition, no one forbids making the legs very high, which will allow to build a table not with one tabletop, but with two.

Didn't find the answer in the article? More information on the topic: