It is very important to have communication with water on your personal plot. This may be a central water supply, as well as a well, built by his own hands. Previously, wells were everywhere, but with the advent of utilities have gone down in history. However, now consumers of water provided by housing companies are often dissatisfied with the quality of the supplied resource, for which they have to pay fabulous money. The solution may be the drilling of a private well or the installation of a wooden well-frame.

A well-built log cabin in the garden allows you to always have access to water and do not depend on public utilities.

How to make a log house for a well is a question that arises from the owners of its own site and causes some difficulties, because it is considered difficult. However, if you follow the exact instructions problems should arise. It is necessary to strictly adhere to these rules:

- The framework for the well is more difficult than for the bath, so the construction should be carried out by two people for safety reasons when working at depth. This should be observed, at least, until reaching the surface. The depth of the mine depends on how deep the groundwater is. If you work without a pair, there is a risk to finish the construction badly.

- The selection and preparation of wood that participates in a wooden house must be careful, because it is about the quality of drinking water. Logs or timber should be cleaned and free from rot, rot and egg laying of wood bugs. Decomposition of organic matter in drinking water will adversely affect health.

- It is necessary to have crushed stone and river sand in sufficient quantity. They line the bottom of the well, which serves as a natural natural filter for the purification of groundwater. Sand can be further disinfected by steaming or by treatment with a chlorine liquid solution. Naturally, before laying it washed.

What is required for work

-

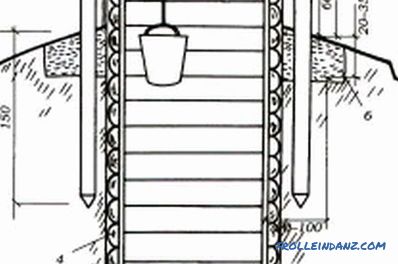

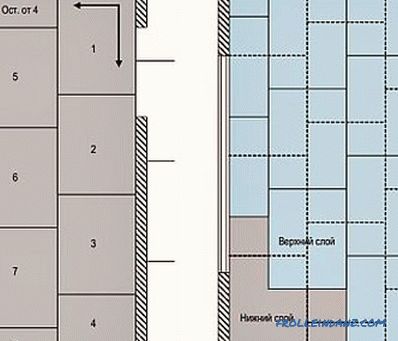

Construction of a wooden well (dimensions in cm): 1. Gate. 2. Piles on which the gate is mounted. 3. Drainage groove. 4. Wooden facing of the well (log). 5. Gravel at the bottom of the mine. 6. Clay castle around the tip.

Spades. Bayonet and soviet. The cutting should not be too long, since it is more convenient to work with a short tool in the limited space of the well.

- Buckets. To raise the removed ground and pumping water manually. In addition, you need a reliable rope.

- Material. Wooden beam or logs. Brackets for fasteners. Bulk material - crushed stone, river sand. Boards for temporary structures and formwork.

- Ax and sledgehammer. The first is used for cutting grooves and locks. The second - for the shrinkage of the timber in depth. Ways of cutting down locks in a wooden house, everyone chooses independently, there are no special instructions here. Usually there is cutting "in the paw."

- Overalls and rubber boots. Work is definitely not for the white coat.

You can use a submersible pump, then manual laborious pumping of water disappears.

Stages of self-installation of the well

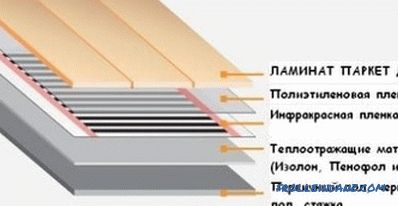

Construction of a wooden well with a pump.

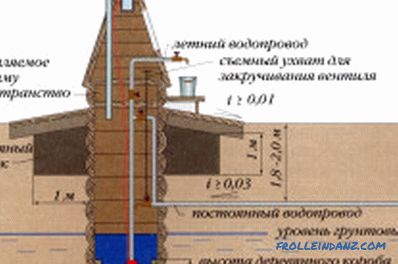

Choosing a place under the well. Besides the fact that the water itself must be found using echolocation or any other affordable method, it is worth considering that the well shaft should not be located near sources of dirt — landfills and compost heaps. But you can not place a well near the house - it is possible leaching of soil and flooding of the building.

Purchase of quality material in sufficient quantity. Bars or logs must be at least 180 mm in diameter. Most of the water species such as pine, cedar or larch stand up to the aquatic environment. Other breeds are good, but quickly rot if above water. You can combine - the bottom in the log house is made from beech or ash, and the top - from coniferous species. Masters should have available a certain number of fasteners. This is usually staples. In the wooden house they are hammered into the corners of the well. Builders need to take care of anti-corrosion coating fasteners - interaction with water will lead to rust. The boards are also useful in work, they are used to precisely fasten and maintain the right angles of the well. This is done temporarily, only on the lower crown.

Before you install the log house directly in the well, the material is cleaned, taking care not to damage the natural protective layer of wood. Then cut the necessary segments, collect log, carefully marking each log or timber. After that, the log house must be disassembled and put into running water for staining. The term of this kind of quenching lasts from one to two years. This is done so that the tree is accustomed to the aquatic environment, swollen, closing all the microcracks and thus not letting the earth layer crumbling from the walls of the well.

The technology for assembling the well’s log house

paint the liquid in color and give it a bitter aftertaste. After quenching, the logs are thoroughly dried and collected according to the marking.

Digging a hole. As mentioned above, the work is carried out by two people, because it is connected not only with the danger of flooding, but also with the lack of oxygen. Its presence is checked using a lit candle. The depth of the well is determined individually, but the width must be at least 1.3 * 1.5 m. That is the size of the cut pieces of logs. Work is done manually using shovels and buckets to raise the ground to the top. This is a laborious process, but the results are worth it. When a layer directly related to water appears, you should be extremely careful - in this case there should be a footrest, and tools and boots are treated with antiseptics to prevent the ingress of pathogenic bacteria. If the groundwater comes in abundantly, a drainage pump is connected to the work or pumped out manually. The aquifer is buried for at least 1 m in order for the water to be able to be cleaned naturally.

The device is the top of the well.

After the pit is ready, the incoming water is pumped out of it and layers of rubble and sand are poured. It is possible to lay the bottom of the well with a brick, but filter layers are still necessary. Next, proceed to collecting the log house directly in the well. The first lay out the lower crown, fastened with temporary boards.

They do it this way - the bottom layer must be in the water - this is the alphabet. Then for each next lap, niches in the walls of the well are carefully undermined, and the crowns are tightly fixed with the help of a heavy sledgehammer, which with its blows will help the crown to sit as tight as possible to avoid gaps. Also, blows with a sledgehammer are also necessary so that the box of the log house does not bulge out and emerge - sometimes it happens. Then begins the next circle in the log house and so on to the top. The height of the well protruding from the ground should not be at least less than 1.5 m.

The final moments of the process

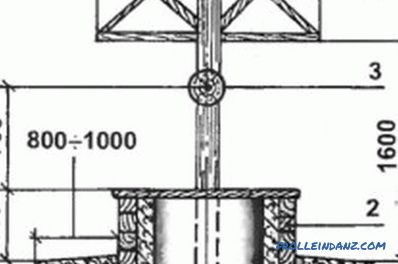

Diagram of the lifting mechanism ( gate) well.

After the excavation work is over, they start to do the upper part of the well with their own hands. A formwork is being built around it. It consists of a layer of clay and concrete. This is done to ensure that groundwater does not flow into the area by the river, but is held back by such a waterproofing structure. The dimensions of the layers should not be less than 1 m from the edge of the log house. Thickness is enough, and 20 cm. After that, you need to take care of a covering building - a roof, from the ingress of rainwater, which now does not carry any cleanliness due to the non-ecological nature of the settlements.

Install the lifting mechanism in the log house - the gate and the chain.

To avoid accidents, install a cover on the well.

This is very important if there are small children in the house. For the convenience of picking up to the tied bucket attached cargo, then it will not float, and immediately pick up the water.

After the final finishing of the well with your own hands, all the water from it must be pumped out. This is done to ensure that the new fluid becomes purified because of the filter pads that are laid on the bottom. In the following days, the water will be suitable only for technical needs. After visually detecting the purity of the water, it will need to be sent for analysis to the local sanitary and epidemiological service, without a detailed report to this organization, water cannot be consumed, even if it is crystal looking. It may contain heavy metals and radiation.

Advantages of a wooden frame before wells or concrete rings

- Cost. Drilling wells and the subsequent casing, cleaning, institution in the house, access roads for large vehicles - all this will cost you a lot of money. Wells and the installation of concrete rings manually can not be done, therefore, will need car lifts and excavators. Shovel and hands - the most budget option.

- Environmentally friendly material. Concrete is a chemical substance capable of transferring its own elements into the water, which necessarily mix in it, and at best, analysis will show it, at worst - it will take a long time to use this water, marveling at its painful state. A wooden log house does not sin with this.

- A wooden structure can be made with your own hands and you can apply all your creative potential in a part of its beauty. The network produces such masterpieces that captures the spirit. Concrete rings and a drilled well are not of particular beauty, and the overall design with a wooden house and a bath is better supported by the same texture.

- Durability. The well over time ceases to function - the house is abandoned or other water-supplying communications are carried out.However, the water in the wooden version will not stagnate and smell bad because of the same environmental friendliness and correct use of the material.

The work on the construction of a well with its own hands is laborious, but does not contain any difficult to understand aspects. All the same, the work is taken, as a rule, not by amateurs, but by people who have at least the slightest idea of wooden log cabins. Information on how to make a well-built blockhouse and what nuances are present in this work are contained in all known search engines on the net.

Didn't find the answer in the article? More information on the topic:

-

The nuances of leveling the chipboard

Leveling the floor chipboard plates accompanied by a number of activities. Preparatory work, installing lathing, mounting chipboard. Practical recommendations.