There are many types of various compounds that are widely used today in repairs. They are needed for the assembly and repair of furniture, for the connection of individual parts of some functional elements. But the most popular among all species deserved exactly thorny connection.

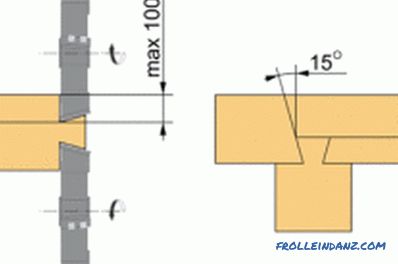

Spike connection is the connection of wooden parts by snug fit into the holes (grooves) of the spikes.

The joint based on grooves and spikes is used mostly for wooden materials. It provides a fairly strong joining, while preventing the deformation of parts. This is especially good for furniture when it is necessary to ensure maximum reliability of fasteners.

Tips for working on connections

Any one can make a spike connection, only before a serious assembly it is necessary to properly train if you do not have any carpentry skills. As a result, you can get a fairly high-quality fixation. And if it is further bonded with metal corners, then the strength of your furniture is at a high level.

Thorn and dovetail groove production.

There are many ways you can make a spike-based connection. But before we consider the main most common of them, it is advisable to consider some rules and subtleties that must be followed while doing the work:

- If you have the opportunity, then make a spike on special precision equipment. This will ensure maximum alignment of the spikes and grooves with each other. Such equipment is in every carpentry shop or an office for industrial labor training.

- It happens that you are going to make furniture that does not require special precision. Then you can make connections with your own hands. To do this, the thorns must be cut exclusively along the grain of the wood. The width should be approximately 17-20 thicknesses of the main part. So you can avoid chipping and the appearance of cracks.

- Things are a little simpler with cutting the spikes on plywood. In this case, the thickness of the spike sinus can be absolutely any. The width of the main parts is not affected. But the principle of conformity in the direction of the fiber remains the same.

- After cutting the spikes and checking their size, the tree should be slightly dried. This refers to the usual keeping of the material in the room throughout the day. So wood can take a permanent form that in the future will help avoid the curvature of the compound.

Tool preparation and the first part of the measurements

Measurement of straight spike connections.

And now we will consider the main and most common version of how you can make a quality spike joint with your own hands. It is based on the use of a regular file or a large saw (depending on the size required).

So, the first thing you need to pick up a tool. It is important to keep in mind that each file has its own cutting width. Therefore, in the end part of the spike will be a little more. And how much - it depends directly on this width. That is why when measuring the parameters of the connection, consider the width of the cut.

Now proceed to markup. For this you need a pencil and a ruler. First measure the parts that need to be interconnected. After this, the width of the parts is applied at the place of the future cut. In this case, the depth of the cutting itself will be equal to the thickness of the main part.

As a rule, in many versions of furniture on one piece, several spikes or grooves may be required. In this case, you need to focus on how they will be the same. If they are identical, it is enough to make one measurement. At different sizes, the required number of measurements is made. Still remember the rule: in thicker parts, the cuts are advisable to do a little less, and in thin parts - deeper.

Markup of the second part

Elements of the spike connection.

After that go to the markup of the second part of the connection. To do this, take the two parts that you intend to connect, and attach them tightly to each other. At the same time it is necessary to monitor compliance of coincidence with the lines of cuts. When the parts are perfectly attached to each other, it is recommended to clamp them in a vice so that they do not move.

Now, when the parts are properly fastened, you need to put marks on the second, not yet marked part with a pencil, and after that make the initial cuts with a file. These will not be solid lines, but simply thin marks that look like scratches. But it is still necessary to do them, since it will be easier to work later. Only when marking, try to do so in order to achieve a perfect flatness and to avoid bends.

After that, it is necessary to release the parts and move them still relative to each other.At the same time it is important to consider this. If you move the parts quite a bit by the width of the file, the connection will be pretty tough. And if you make a little more movement, it will be more free.

It is not possible to say that one of the options is bad. It all depends on the nature and size of the parts to be joined. And also on the specific type of wood used. If you use plywood, then you can only make shifts across the width of the cut, since in any case it will not be subjected to severe deformation.

Final formation of spike connections

Methods for spike connections of wooden parts.

When all this is done, proceed to the thorough formation of spikes and grooves. In order for everything to go right, you need to constantly take measurements while working to eliminate the risk of error, if possible. Pay particular attention to the evenness of the lines. For larger parts, use to control the building level.

So, the main part of the work is over: spike connections are formed. Now you need to finally measure everything to make sure that it is correct, after which you can proceed to the final design. To do this, you can use sandpaper or jigsaw. It depends on how rough the surface is.

Next is the connection. It is important to consider the type of connection. They are detachable and one-piece. Fixed connections must be stronger and more solid, and split connections so that they can be disassembled when the need arises. Glue is used for permanent joints, and for detachable joints, it is necessary to slightly round the corners.

The option of how to make spiked joints with your own hands has been considered.

There are several other ways, but they are already more complex and more suitable for professionals. But if you do not hurry anywhere, then gradually you can acquire skills and perform the following work simply.

Didn't find the answer in the article? More information on the topic:

-

Technology of laying lining inside the house

Laying lining: preparatory work, the manufacture of frame construction, fixing the insulator and vapor barrier. Installation of lining in different ways to the surface of the frame, painting the lining.