The motor-cultivator is an indispensable tool for gardeners and gardeners. The main tasks of the soil cultivator include plowing and loosening the land, as well as hilling, cutting furrows and harrowing the soil. This type of agricultural machinery is quite popular and relatively easy to use. However, when choosing a unit, it is important not to lose sight of its quality, performance and price. After reading this material you will learn how to choose a motor-cultivator, what kind of power the unit needs, what type of engine and transmission is the most practical and reliable, as well as features of the service and types of additional attachments.

What is the difference between a motor-cultivator and a motor-block

First of all, when choosing a motor-cultivator, you need to decide on the tasks that you have to do with this technique. And here it is important to understand what you need - a motor-cultivator or a motor-block.

Motor-blocks are aggregates similar to motor-cultivators, but having certain differences. The motor-block, as a rule, is more powerful equipment and can be compared only with motor-cultivators of the heaviest class. In addition, this device is more versatile. The motoblock can be in two versions - with and without a power take-off shaft (PTO). On units equipped with a PTO, you can hang active attachments in the form:

- Snow removal decks;

- Hay and lawn mowers;

- Sweeping brushes;

- Scarifiers and cutters for soil preparation and much more.

You can also install the wheels and trailer. Thus, you get a kind of tractor for the transport of goods. However, walking tractor, even without additions, will cost much more expensive than a garden cultivator. And the hinged elements from the above list sometimes cost more than the device itself.

Which of these two gadgets is better? Depends on the scope of use and your needs. Of course, if the technology requires maximum functionality, you should take a closer look at the walk-behind tractor. But if you are a simple summer resident and are looking for a mechanical assistant only for land works, this unit will cause unnecessary additional expenses. It is better to stay on a motor-cultivator. With his tasks, he will cope no worse, but it is worth while at times cheaper.

It is also worth noting that some models of motor-cultivators are not inferior in their characteristics to motor-blocks. We'll talk more about this very soon.

On the left is a motor-cultivator, to the right a motor-block.

Device and types of motor-cultivators

The first motor-cultivators were created at the beginning of the XX century. The device was put into operation with a heavy electric motor, for which a constant voltage from the mains was needed. The thing is that at that time there were no compact and at the same time powerful internal combustion engines. As a result, gardeners got tired no less than after manual work, and the cable that connected the device to the network significantly limited the range. Modern devices got rid of various shortcomings of their old brethren.

If you do not go deep into the technical features of these devices, then we can say that the motor-cultivator consists of the following components:

1. The power unit, in the role of which can be an electric motor or an internal combustion engine; 2. Transmission; 3. Running gear; 4. Controls.

Depending on the power and weight, there are 3 types of motor-cultivators:

- Light;

- Medium;

- Heavy.

Light - a budget option for amateur gardener

Their weight ranges from 9 to 30 kg. A power, usually in the range of 1 - 3.5 liters. with. Compared to more powerful models, light motor cultivators have only one drawback - the inability to use in large areas. The maximum area on which it is recommended to work is 15 ares.

However, there are clear advantages in lightweight models:

Affordable cost. The power of such equipment is low, which directly affects the price. Such cultivators will be cheaper than other analogues;

Mobility. Transporting a device usually does not cause any problems. The motor-cultivator easily is located in a car trunk. A relatively small mass of technology allows you to independently transfer it;

Working in hard-to-reach places. A light and compact motor-cultivator will cultivate the ground in the corners, between the beds, near trees and other places where it is impossible to use more dimensional equipment.

The simplest models with power up to 1.5 liters. with. suitable only for already developed lands and capable of loosening the soil at a depth of 10 cm. They have only one front gear, and the speed of rotation of the mill is 130 rpm.Densely trampled earth or virgin land does not succumb to attempts of a weak soil cultivator, therefore the demand for them is low. But if your goals for working with the site are not global, and the land has been previously processed, you can look at the device with a similar capacity. It is also worth noting that such basic units of the unit as the engines and gearboxes of these devices are not maintainable due to their low profitability. Often, such devices are equipped with electric motors.

But, as already mentioned, the power of light motor-cultivators can be higher - up to 3.5 liters. with. Such devices can be a great helper for the gardener. Their weight is 20-30 kg. In this case, cultivators have not one, but two speeds. The first gives up to 130 revolutions per minute, the second - about twice as much. This technique is able to cultivate the ground to a depth of 20 cm. But the width of the cutters of such a unit usually does not exceed 35 cm, which is a drawback, since it will take more time to process the area.

Easy motor-cultivator in work.

Medium - the best option for a gardener or amateur gardener

These devices have a weight of 40 - 65 kg and a capacity of up to 5.5 liters. with. They are usually equipped with three gears (2 front and 1 rear), capable of processing the soil to a depth of 35 cm, and the width of the aisle is up to 85 cm.

and gardeners semi-professionals. Often used in areas of small and medium area, which require regular tillage (2-3 times a year).

Their average weight is 50 kg, which makes the device stable and gives additional comfort to work. In addition, these cultivators have enough power to additionally install various additional equipment, such as a mounted plow.

Another advantage is the ease of handling. If you have never picked up a soil cultivator, do not worry. A new acquisition is not an abstruse mechanism with which one cannot understand without instructions and 100 grams. Everything is simple, reliable and efficient.

The average motor-cultivator in work.

Heavy motor-cultivator or motor-block

Often such a device is compared with a motor-block, their power is more than 5.5 liters. c, and weight over 70 kg. With it you can already plow vast areas of virgin. This unit can be used both in small farms and gardeners by amateurs.

Their capacity is sufficient to handle an area of 1-2 ha. Models with 9 "horses" without problems plow up to 5 hectares. The depth of tillage for such devices is 20 cm, and the cutting width of the cutters is more than 60 cm. The device allows you to install various additional mounted components and even a cart. The last motor-cultivator is able to tow with a mass of up to 300 kg (the exact figure depends on the model chosen). The main drawback of the device is the high price. But given the characteristics of technology, nothing surprising in this.

Heavy tiller in operation.

How to determine the power unit of a motor-cultivator

Electric motors and internal combustion engines are installed on soil cultivators.

Cultivators with electric motors

Such units are driven by a special electric motor. In turn, the engine runs on the network, and connects their long cable. Everything is like at the beginning of the 20th century, only more powerful and lighter. In addition to small dimensions, the advantages of technology include the absence of harmful emissions into the air. When using the device, you do not have to inhale the exhaust gases, which are in excess of air.

But the main drawback of the electro-cultivator is the cord. First, it impairs its mobility, since if there is no outlet nearby, it is necessary to plow the land manually. Secondly, you need to monitor the safety of the cable. If it is damaged by cutters, there is a possibility of an electric shock operator, which can lead to injuries. The cost of technology is relatively low, but you should not expect high power. It usually does not exceed 2–3 kW (approximately 2.7–4 hp).

Suitable aggregate for digging and processing flower beds, front gardens. Also used in enclosed spaces where cultivators with an internal combustion engine cannot be used. Greenhouses, greenhouses and conservatories can be processed either manually or using an electric cultivator. To take a shovel and a rake into the hands of very few people would like, and the presence of exhaust gases, which the internal combustion engines (internal combustion engines) leave behind after their work, in enclosed spaces is simply unacceptable. Therefore, electro-cultivator is the best option in this case.

There are also cultivators with an electric motor that run on a battery without any cables.And this is the only noticeable difference between the models mentioned above. The battery is more mobile, but does not exceed in power. It is usually used on small areas when processing only the top layer of soil.

Motor-cultivator with internal combustion engine

Motor-cultivators working on gasoline are the most popular. They have almost no power restrictions. The only thing that can push away from the purchase is the high price.

Petrol motor-cultivators are more difficult to maintain. The engine should be periodically cleaned of dust and earth residues and perform other maintenance procedures. Neglecting them can lead to malfunctions, or even serious damage. Due to exhaust emissions, the device cannot be used indoors.

Motor-cultivators can be equipped with two types of internal combustion engines: two-stroke and four-stroke.

1. Two-stroke. They are cheaper and 60-70% more powerful than four-stroke counterparts (with the same dimensions). But there are drawbacks. The first - efficiency - the engine consumes more fuel. The second is reliability and resource. To avoid serious damage, you should use only high-quality fuel and oil. In addition, be sure to adhere to the recommended proportions of mixing ingredients. Otherwise, the failure will come much earlier than the allotted time. On a motor potential two-stroke engines always lose four-stroke. By the way, the repair of "two-tactics" usually costs quite expensive. Therefore, the damaged equipment is sent not to the workshop, but to a landfill. The owner is sent for a new purchase. To meet this type of engine is possible only on light models of cultivators.

A motor-cultivator with a two-stroke engine.

2. Four stroke. Practically all new models are equipped with this engine. The first tangible advantage compared to the previous option - increased comfort. They boast less noise. Mass is also different. Four-stroke is heavier, which only improves the work of machinery when plowing and loosening. Differs engine and its "purity". Harmful emissions into the air at the "four-tactics" are much less. And most importantly, the technique with this engine will last longer.

It is widely believed among gardeners that while working with a gasoline cultivator, periodic breaks should be taken in order to cool the engine. But in fact it is not at all necessary. To raise the temperature beyond the norm, you need to spend far more than one hour. In addition, the tank equipment has a limited amount, which is enough for several hours of work. Accordingly, from time to time you will have to be interrupted for refueling. During these few minutes, the engine will have time to cool down until the next refueling (if it is needed).

A motor-cultivator with a four-stroke engine.

What you need to know about the transmission

You already know which cultivator to choose depending on weight, power, engine type and other factors. But for the right choice do not forget about the transmission. Much depends on the type of gearbox and clutch: reliability, comfort during operation and layout of a motor-cultivator.

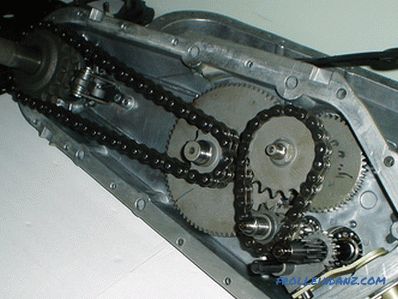

Reducer of the unit

The reducer is designed to transmit torque from the engine through the clutch to the wheels or working parts of the cultivator. From the reliability of this site depends largely on the duration of operation of the entire unit. Usually motor cultivators use chain, worm or gear transmission.

1. Chain Reducer. The chain gear is placed on soil cultivators whose engine crankshaft is horizontal. This is the most popular solution since this gearbox has the greatest resource at low cost. When buying a cultivator with such a gear, you need to pay attention to whether the gear is collapsible. If it is collapsible, then almost all the damage that may occur during operation can be eliminated. The most likely faults are: stretching and open circuit; damage to the sprockets, cutting the keys on the drive ox. All these faults are easily solved with the help of a service center or even independently.

2. Worm gear. With a vertical arrangement of the crankshaft, a worm gear is used on light cultivators. It is distinguished by its relatively small mass and compactness. Installation of such gears on light cultivators due to the fact that they can not withstand heavy loads. With the help of such a reducer, the cultivator will be able to loosen the already cultivated land, but it will not fit on more serious things. For example, this type of gearbox does not allow a plow to be hung or a trailer attached, sinceThis can lead to breakage due to high loads.

The worm gearbox is characterized by large friction losses and rapid wear of the brass gear, as well as heat and the formation of the output shaft play. In addition, this type of gearbox has the unpleasant effect of self-braking. This means that during the pushing of the cultivator, its cutters or wheels will not turn, regardless of whether the clutch is engaged or not. Special wheels or strong hands are necessary for movement.

3. Gear reducer. This type of gearbox is the most reliable and designed for continuous operation. As a rule they are equipped with powerful motor-cultivators. The downside of such a device is its price.

4. Gear - chain reducer. It is a kind of compromise between chain and gear reducers. It improves the performance properties of the cultivator while not adding much to its cost.

Clutch

There is a clutch on motor-cultivators that has three types:

- With clutch release (motorists will understand);

- Belt with mounted tensioning roller;

- Automatic centrifugal (exactly the same as on the chainsaw).

The release clutch is installed on professional models that are designed for intensive and long-term work. It is the most preferred option. Coupling with a tension roller is installed on devices from an average price category. Budget cultivators are equipped with a centrifugal option.

Reverse

It is good when the motocultivator is equipped with reversing. This makes it much easier to use. Motor-cultivators of a light class, as a rule, do not have such a functional.

Number of gears

It is desirable that the cultivator has two or more gears. This makes the unit more versatile and convenient to use.

Recommendations for choosing a motor cultivator depending on the area of the plot

will be applied and its performance. Productivity - the area of the territory that was cultivated by the cultivator for a certain time period. This indicator depends on the two main characteristics of the motor cultivator: engine power and the width of the grip. The more these indicators, the higher the performance.

This parameter should be checked before purchase and at the same time take into account the size of the area where the work will be carried out. It is important that there is enough power. But it is also not at all necessary to spend money on the most expensive models of machinery, if medium cultivators are enough for work.

Many gardeners who have had to work with both simple and more powerful motor-cultivators insist that the number of "horses" directly affects the life of the machinery. But is it really so?

Directly - no, but indirectly - yes. The thing is that often when working with weak cultivators, gardeners work at the limit of the device. Accordingly, the main work items fail faster. Moreover, if you constantly squeeze the most out of powerful equipment, it will also break. However, the advantage lies in the fact that it is almost impossible to reach the limits of such motor cultivators. Thus, they always work in "comfortable" conditions and last much longer.

| Plot area | Recommended cutting width, (cm) | Recommended power, (hp) |

|---|---|---|

| Less than 15 acres → | 60 | 3. 5 |

| from 16 to 60 hectare → | 80 | 4. 0 |

| from 61 to 99 acres → | 90 | 5. 0 |

| from 1 to 2 hectares → | 90 | 6. 0 |

| from 2 to 5 hectares → | 90 | 9. 0 |

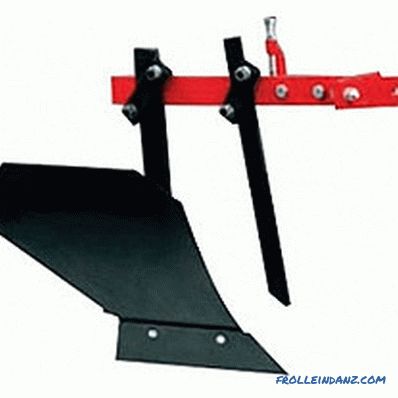

Attachment

By default, the garden tiller is equipped with cutters and wheels for transportation. This is more than enough for tillage. But if you set tasks for a technician more globally, you need to take care of acquiring attachments. The most popular are the following types of attachments.

Grouser

Plow for processing virgin

Potato harvester

Lawn Slotter

Hiller

Scarifier

Practically all elements are attached to the trailer part of the cultivator.The exceptions are cutters and grooves, which are mounted on the shaft of the cultivator. Fixed attachments with bolts and nuts, or studs and cotter pins. The first method is more reliable. But the second can be used if there are no tools at hand. All these additions will allow you to create a universal device that will take all the manual work with the soil on yourself.

Remember that you need to use attachments that are specific to your cultivator model.

Maintenance

The mechanisms of motor-cultivators in work and care are unpretentious. The only element that needs special maintenance is the gasoline engine (it’s enough to clean the electric one from dust and earth).

When using a gasoline cultivator, the following rules should be followed:

Rule 1. An oil change should be carried out every 100 hours worked . Engine oil must comply with the following viscosity coefficients: 10W-30 for summer operation. In late autumn, in winter and in early spring, it is better to prefer 10W-40.

Rule 2. If the equipment has been out of work for a long time, for example, from the previous season, it is recommended to drain gasoline or add new fuel;

Rule 3. Periodically, it is necessary to check the air cleaning filter. If necessary, it must be purged or replaced with a new one.

Rule 4. Gearboxes can be either collapsible or non-collapsible, i.e. not serviced. In collapsible gearboxes, lubrication must be monitored.

Rule 5. The coupling device requires periodic cleaning from dirt.

Now you know which cultivator is better to buy for the garden or your garden. Correctly determine the goals and objectives that you set for equipment. Calculate budget and specifications. Then pick up a decent machine is not difficult.