Copper pipes are often installed today in heating networks, as well as in the water and gas supply lines of residential buildings. In addition, these products are widely used in air conditioning systems and freezing devices of various types.

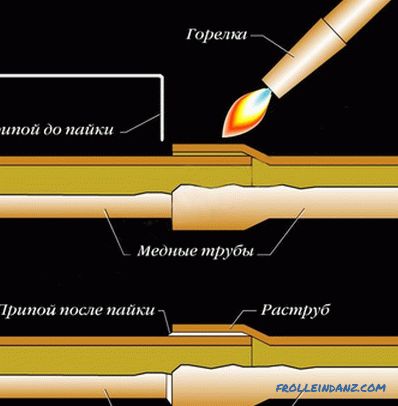

Special soldering techniques have been developed for receiving the permanent pipe joint, which is realized by introducing special molten material (solder) into the contact zone. In this case, the required quality of the connection is achieved only in the case when the melting point of the solder is below the melting point of the pipe elements being joined.

We note right away that soldering copper pipes with your own hands will require you to be especially careful and have a certain preparation.

Advantages of brazed copper structures

Brazing copper

Brazing copper

The growing popularity of systems assembled based on copper pipes, is easily explained by the presence of such attractive qualities as:

- reliability, durability and strength;

- ease of processing the source material;

- ability to function at high pressures and temperatures.

In addition, due to the use of such technologies, it is possible to save on component materials (fittings, adapters, etc.), which markedly reduces the total cost of the work performed.

Soldering methods and tools

Soldering process

Soldering process

Soldering copper pipes can be done in one of the following temperature regimes:

- High-temperature soldering (the temperature of the melt is about 600-900 degrees) is used for pipelines operating under high loads.

- Low-temperature mode, usually practiced in everyday life (the temperature in the soldering zone is up to 450 degrees).

Pipe cutter

Pipe cutter

The following tool should be used to obtain a reliable joint of the pipes during the soldering process:

- Pipe cutter, with which you can get a smooth cut (perpendicular to the axis of the pipe billet).

- Special fixture used for chamfering and deburring.

- A pipe expander that allows to prepare the joint for soldering (the depth to which the pipe is processed with its help must be equal to the diameter of the workpiece).

- Acetylene gas-oxygen burner used for brazing copper pipes.

Using the Expander for pipes

Using the Expander for pipes

Depth to which the pipe is machined using the expander, must be equal to the diameter of the workpiece.

Electrohydraulic tube expander

Electrohydraulic tube expander

In addition, a special one can be used to work with low-melting solder thermal dryer, which provides heating of the weld to the desired temperature.

The use of a heat gun allows you to easily adjust the temperature in the weld zone, as well as to maintain the desired temperature. With the help of the replaceable nozzles supplied with the device, you can direct a stream of heated air to the desired point.

Materials used in soldering

Copper pipes of different diameters

Copper pipes of different diameters

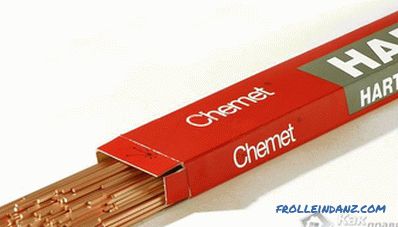

Before how to solder copper pipes, you should be familiar with the materials that act as solders, which, depending on their refractoriness, are divided into hard and soft.

Solders

Copper-Phosphor Solder

Copper-Phosphor Solder

Solders of increased refractoriness are made, as a rule, in the form of rods of a certain profile. The use of solders of this type is possible when heating the soldering zone to 900 degrees, which allows to obtain a very reliable connection. Solders of this class are often used in the installation of water and gas supply lines, as well as in the repair of freezing equipment and air conditioning systems.

The most well-known representatives of such solders are copper-phosphorus self-fluxing mixtures with various additives (Cu94 P6 and Cu92 P6 Ag2). Small additives (about 6%) of phosphorus or silver can reduce the melting point of the solder to 750 degrees. The coefficient of expansion of this material coincides with the same indicator for copper, which contributes to the formation of a strong and reliable connection.

Brazing of copper

Brazing of copper

The so-called "soft" solders are made in the form of ordinary thin wire and serve for low-temperature soldering of copper pipes produced at home. These solders are made, as a rule, on the basis of such known materials as tin, lead (or their alloys).

Fluxes

To facilitate the soldering of copper pipes, special liquid or paste-like compounds (fluxes) are used, the success of which depends on the correct choice activities in general.

These compositions are also divided into low-temperature (up to 450 degrees) and high-temperature, used at temperatures above 450 degrees.

They help:

- to clean the place of soldering from oxides;

- to protect it from oxygen contained in ambient air;

- to create conditions for a smooth the spreading of the soldering composition;

- improving the adhesion of the metal to the solder.

Soldering with an electric soldering iron

Soldering with an electric soldering iron

During soldering work, it is necessary to carefully ensure that The solder heated to the required temperature evenly spread over the surfaces of the articulated blanks, thus forming a reliable articulation. After the final cooling of the site of soldering, remove all excess flux from it.