A sliding table is comfortable and compact. But not everyone has the opportunity to buy it, since the price of a sliding table is quite high. But all the craftsmen who are ready to create household items with their own hands, have the opportunity to make it yourself. Tabletops can be made with your own hands, using glass coating or wooden. Glass tables or from natural wood look very nice. But since natural materials are not cheap, it is better to entrust the legs and the tabletop to specialists, so as not to spoil the wood. Very beautiful sliding tables - on one leg.

The sliding table is very convenient and compact, it can also be made with your own hands, using glass or wooden covering.

The design can be chosen at will, for example, to make the legs chiseled or figured. The sliding table will have the following dimensions (in millimeters):

- table height - 775;

- table width - 885;

- table length - 1245;

- insert - 375.

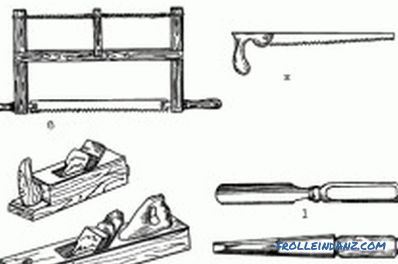

Materials and tools that will be needed when modeling

Tools for making the table.

In order to make such a sliding table, not so much material is needed, so the piece of furniture will be inexpensive, but practical and beautiful. The most important thing is that all parts have the right size and be symmetrical. The following materials will be needed:

- wooden bars (legs) - section 85 \ 85 mm, length 745 mm;

- frames connecting the legs (width - 105 mm, thickness 30 mm): 2 pcs. 925 mm long (+ 2 spikes - 40-55 mm long), 2 pieces of 485 mm each (+ 2 spikes, 40-55 mm long); 14> 2 wooden surfaces for a tabletop of the same size - width 805 mm, length 625 mm;

- insert detail of the tabletop - width 375 mm;

- for the tabletop it is better to choose a wood panel (thickness 35-45 mm);

- a sliding mechanism;

- wooden spikes for connecting frames (diameter 9-11 mm);

- a drill to create nests into which spikes are then inserted;

- self-tapping screws for installing a sliding mechanism;

- glue for wooden surfaces (you can use PVA) ;

- machine for grinding wooden surfaces;

- abrasive paper;

- varnish for coating wooden surfaces;

- brush;

- ruler .

Sliding table do it yourself - build

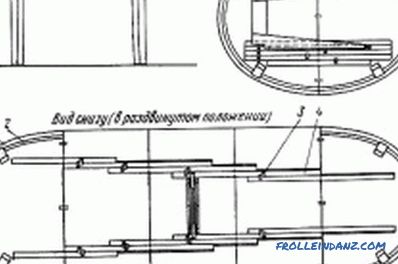

Sliding table device layout.

Once the parts have been assembled, the modeling process can begin. First of all, it is necessary to mark the nests on wooden blanks for legs. The spikes of the frames for connecting the legs will be inserted into these sockets in the future. In accordance with the diameter of the spike need to make holes. It is better to put the spikes on the glue, in this case the structure will be much stronger.

First you need to assemble the underframe and only then proceed to the assembly of the main parts. A prerequisite - matching at the ends should be as accurate as possible. Placing spikes in the nests, assemble the structure. It is not recommended to glue the parts at once, it is better to first assemble the entire table, see firsthand whether the dimensions and joints are the same, and only then glue the parts.

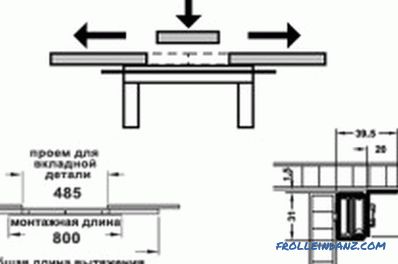

After all the above steps, you need to do the installation of the insert. Some differences in the level of one or several parts are possible, which can be easily eliminated with a grinding machine. The mechanism for the sliding table is mainly made of aluminum. Installation is carried out either with screws, or by gluing.

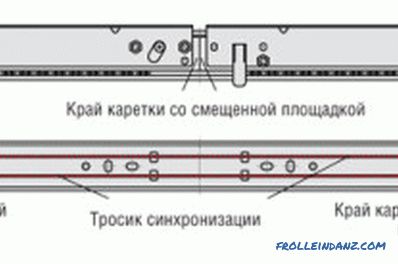

Aluminum roller guides for the sliding table.

The next step is to install the sliding mechanism. It is easy to attach it, it is enough to fasten the guides to the long frames, and each of the sliders - to its part of the table top. It is better to mount the sliding mechanism by turning the table on the tabletop. After installation of the mechanism it is necessary to check how the central insert will be installed.

Under the worktop, you must install two slats of the same length as the wooden center insert. This should be done for ease of use - when the insert board is not needed, it will be under the table top and held in place with slats. After the assembly process, the finished product can be coated with stain.

Round table is considered to be true chic and luxury. Today they are the most expensive in the market, especially those made of natural wood. It is also possible, most importantly, to have the desire to make a sliding table with your own hands round.

A sliding table with your own hands of a round shape

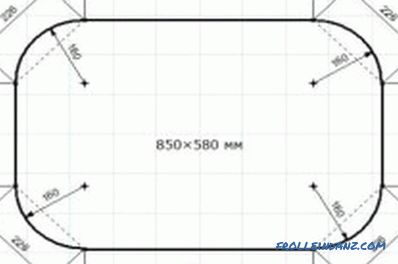

Size chart of the sliding table.

In principle, the technique of assembling a round table does not differ from the above described technique. The only thing that the edges of the table top will have a rounded shape.For its manufacture you will need:

- drawing paper;

- scissors;

- any glue for a wooden surface;

- leg timber;

- simple pencil;

- ruler;

- boards;

- 8 mm plywood;

- self-tapping screws;

- screwdriver;

- hacksaw.

From the drawing paper with the help of a large compass you need to cut out the shape of the future table top. Only then cut it out of wood. What kind of countertop will be - glass or wood, depends on the desire of the owner of the future sliding table.

Glass and wooden sliding tables look much more beautiful if they have one figured leg.

What you need to know about assembling a sliding table with your own hands

All about the tabletop

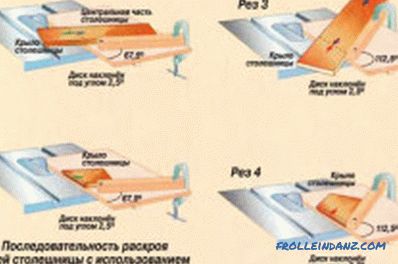

The tabletop cutting layout.

First of all, it is necessary to decide what material and form the table will be from. Perfectly suited pine or chipboard. Naturally, the pine board is preferable, since it is much stronger, in addition, pine boards are environmentally friendly. Boards are cut and processed according to the size of the future table top. In the event that the table is still made of chipboard, the sheets need to be drawn into 3 parts, 2 of which will be the same size, and the 3rd part will perform the function of insertion in the center of the table top. Before you assemble this piece of furniture, it is better to draw a drawing or use ready-made drawings. For it to be strong and last for a long time, it is necessary to maintain accuracy in the calculations. Only in this case it will not "float" and will be durable.

Legs

Legs are mainly made from bars, which can be purchased at the store. The colors of the table tops and legs should be either the same or differ in color by 1-2 tones. And the tabletop should be darker. A prerequisite for the manufacture of a sliding table with their own hands - the proportionality of the size of the tabletop and legs. Too thin legs will not be able to hold a large tabletop. The length of the legs should correspond to the general appearance - a small coffee table will not look with long legs. But if the idea is an unusual sliding table, then special attention is paid to the layout of the center of the bar. Legs can be made curly. It is also possible to make a figured leg on your own. To do this, it is enough to study the technique of cutting out figures from a tree.

Tsarga

Mechanisms of external attachment to the tsar of synchronous extension with a lock.

Tsarga - these are the slats that connect the two parts with their ends. In order to do the markings of the tsargi, it is necessary to lay the tabletop on a comfortable surface "face" down, but before that it is better to spread a soft cloth so as not to damage the surface. It is better to make each of the blanks of the tsarg slightly larger than the estimated size. Surplus can always be removed, but the shortcomings of length - no. Tsarga is processed by a lathe and a router.

Everything about the assembly

The most important stage is the assembly. Special attention should be paid to the connection of the side frames with the leg or legs. To do this, each spike must correspond to a previously prepared groove. Do not forget about the grooves - they provide a strong connection. Applying glue to the strength of the structure, after drying, all its excess must be removed with emery paper. In any work there may be inconsistencies, for example, mismatched edges of the table top. This is easy to fix with a grinder. Then clean with sandpaper and varnish the surface.

Advantages of sliding tables

The main and obvious advantage of a folding table, which is made by hand, is its versatility. A special mechanism helps to make a big dinner out of a small compact table. That is why it is convenient for small apartment rooms. It does not take up much space, but allows you to seat about 9-10 people.

Due to the fact that there is a huge amount of material on the trading market for creating a sliding table at home, it can be made not only multifunctional and convenient, but also beautiful and stylish.

Classify tables that are moved apart as follows:

Transformers.

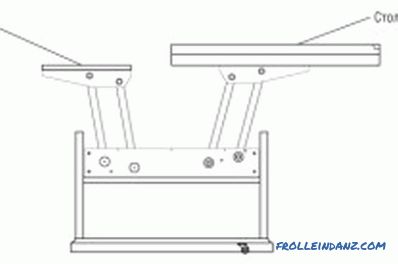

The unfolding mechanism of the table transformation mechanism.

Sliding tables have received this name due to their unique ability to reincarnate. From the seemingly small table, you can get quite roomy dining. Forms tables transformers round or oval. The main feature of these tables is an increase not only in their size, but also in height. You can make such a table with your own hands. It’s enough to have a drawing. In addition, transformers have recently been particularly popular not only because of convenience, but also because of design excellence. Mostly transforming tables are made of wood or glass.Mirrored look very nice and allow you to save a lot of space in an apartment or house.

Standard sliding tables.

Tables of such types are not less popular. They are made of natural wood, fiberboard or particleboard. The advantage lies in their compactness. In addition, to make the sliding table with their own hands will not be easy. It is enough to follow the instructions for their construction.

Any extendable table is comfort and versatility. All of them are practical and economical. You can make a table not only for eating, but also for drawing, games. A sliding table built with your own hands is a wonderful way to make a children's room comfortable and stylish. In addition to all the advantages, it is much easier to transport sliding tables than usual ones.

A sliding table for a child's room, made by hand, is an ideal solution, especially if there are several children in a family. In addition, it can be combined with the bed. Well, the most important positive side of the sliding table do it yourself is its economical cost.

Didn't find the answer in the article? More information on the topic:

-

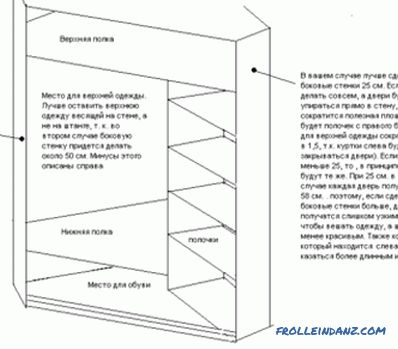

How to make a corner cupboard with your own hands

Instructions on how to make a corner cabinet with your own hands. What materials can be used? The complete process from cutting to closing edging. Features of the workflow.