To make your own rafters, you need to carefully consider all stages of work. Problems with them will not arise if the work is performed in strict sequence and with careful observance of technology.

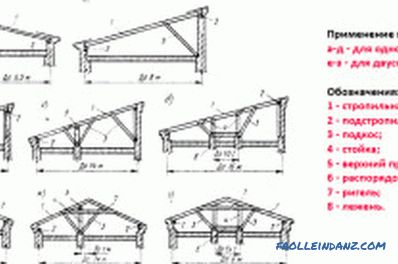

The device truss system.

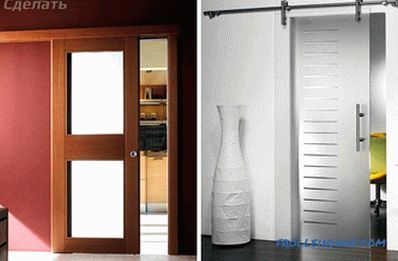

The type of roof selected for the device

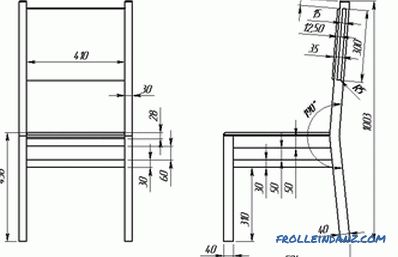

To make the rafters for the roof with your own hands, you must determine the type of construction of the future roof. Different rafters are suitable for different roof options. It is recommended to take care in advance of drawing up a drawing where all disputed points will be visually reflected.

Shed roofs are mainly used for household buildings, extensions, baths, sheds, premises for livestock. Rafters in this case can be arranged without the involvement of professionals and save a little on this. But there are such buildings where the use of single-pitch roofs is not considered practical. After the type of roof is determined, you need to think about what material will be used for the coating. The weight of materials for the roof must always be taken into account at the stage of calculating the rafters.

Material for rafters

When choosing material for rafters, you should pay attention to conifers, as they are very high quality and strong.

It is necessary to choose wood for the rafters, which managed to “cope up” well. When the whole roof is ready, this material will not change its shape. The choice of wood for the roof system will to some extent affect its durability.

Conifers are considered to be one of the best options for making rafters: they are perfectly treatable, quite affordable. For rafters choose a bar with a width of 10-15 cm, a thickness of approximately 5 cm. The length is chosen in accordance with certain conditions of construction.

Wood for rafters should have good strength. It depends on the conditions in which it was prepared, on the place where it was stored, on its climatic conditions, on the quality of drying. Preference is better to give resinous bars. Resin is a natural antiseptic, wood with it can be well preserved, and the time that such rafters can last is longer.

Versions of truss structures.

Careful attention should be paid to the choice of a bar that is designed for end rafters. Most often, the joints between the planes become quite problematic places. They are not particularly strong and are highly susceptible to leakage. When connecting several bars in one place of the rafter to install, you must choose the ones that are more specific.

A bar should be provided with good protection against fires and the appearance of pests. Wood is treated with antipyretic chemicals designed to reduce inflammability, antiseptics that prevent material rotting. Such measures should be taken in advance, while the elements have not yet been assembled into a single system. This approach to work allows you to properly handle hard-to-reach areas.

For applying protective compounds it is better to use brushes with a long pile and sufficient width. In this case, you must wear a respirator and protect your eyes with glasses. Processing should be carried out in several layers, each of which must be well dried before applying the next. Usually 2-3 layers are enough. Substances need to saturate the material well. Only then can wooden elements be installed in the truss system.

The most demanded trusses

Regardless of the type, truss systems are interconnected fasteners and beams.

The responsibility of the structure made up of them is to evenly distribute the load on the base.

The reliability of the future roof also depends on how carefully the calculations are performed.

Scheme and installation of hanging rafters.

Roofing systems are more often performed in one of two options: they can be trailing or sliding. The latter are the most common. Their difference from other systems lies in the support of truss legs. When creating a slant truss system, the emphasis is made in a bar located along the perimeter. In the center usually arrange a ridge run. To increase the strength of the structure, the rafters are supported by beams.

Another equally popular option is hanging rafters. With such a system in the design, if necessary, you can install additional racks. So it will be possible to best distribute the entire load.

When choosing any of the options, a scheme should be drawn up in advance, where the location of all elements of the system is taken into account.

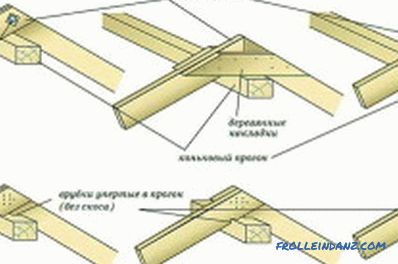

Previously, only steel staples and nails were used to fasten the truss structure. Now, in order to securely install the rafters, it is better to use modern fasteners: studs, metal fastening plates, various corners.

What is the rafter system made of?

Rafters are part of the supporting structure of the roof. The rafters of the nylon type are made up of elements such as:

- lying;

- runs;

- rafter legs (bars located along skates);

- racks;

- struts.

Railing rafters.

The main task of rafter legs is to protect the roof from deflection caused by its own weight of the structure, and under the influence of the severity of snow cover. Other components distribute the load on the supporting pillars and walls.

Suspended structures are mainly built when vertical pillars are to be installed. They are arranged in increments of less than 8 m. Not very large spans overlap the rafter legs, placing them at a distance of 800-1200 cm from each other. To make the construction stronger, it is necessary not only to carefully carry out all the calculations, but also to bear in mind that additional racks may be required. When the device is based on the sunbeds. If the need arises, they will be able to support the run well.

When installing the rafters on your own, you must do everything in such a way that the ends of the legs come up against the girders, and at the bottom - into the mauerlat. He, in turn, must be attached to the top edge of the wall. So the load is partially redistributed. For stability, you should also build a rafter frame.

How to install the rafters with your own hands?

The installation of the truss structure is carried out in stages.

Structures for fastening rafters.

At first, the timber mower plate is laid, which holds almost the entire truss system. Mounts are installed in it: their pitch should be no more than 120 cm. To create hydroprotection, a roofing material or other insulating material must be laid under the mauerlat.

In the timber mark those places where there should be holes for studs, and drill them. The studs are threaded into the mauerlat so that they protrude slightly, and the fasteners are fixed using washers and nuts. After that, the rafters are attached to the power plate.

The rafter leg must be set to the desired position, after which it is attached to the power plate using steel brackets. They help to prevent displacement of rafters. Also fasten rafters with the ridge part of the system.

To further strengthen the ridge section, you can install diagonal slats. The design will be similar to the letter "A". More often they do this when hanging rafters are installed. If studs are used for fasteners, they should not be greater than 8 mm. This is suitable if a lightweight coating like Ondulin is chosen as the roofing material. For heavy ceramic tiles, for example, studs should be selected in 10-12 mm.

In some cases it is necessary to lengthen the bar. Connections are overlapped using particularly strong studs with a diameter of 10 mm or more.

Fastening the rafters to the power plate

When erecting roofs of some forms, the length of the rafter bars may not be enough. To eliminate sagging structures, the roof will need to be further strengthened. To do this, you can put a girder in the middle of the system so that the load is evenly distributed, or install cross beams and struts for the same purpose.

After the installation of the truss system is completed, trimming of the rafters should be made along the entire level of the eaves. Then you can go to work on the device waterproofing.

Didn't find the answer in the article? More information on the topic:

-

Types of lacquers for applying to wood

Types of wood varnishes: composition and main characteristics. Requirements for wood varnish. Criteria for choosing varnish on wood. The principle of operation of varnish for wood.

-

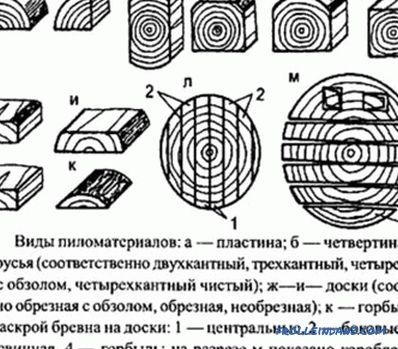

Lumber grade characteristics

Determination of grade lumber. Wood calibration. The use of materials of different grades and their differences. Determination of the nature of the moisture content of timber.