Having got involved in building their own home, every person who wants to create a warm and cozy structure for himself and his family, at some point faces the problem of choosing insulation materials. In the modern market of materials for this purpose very much, they differ in different properties and indicators. This mineral wool and stone, as well as more modern materials such as polystyrene foam. But even the most expensive insulation - this is not yet one hundred percent guarantee that the building will be completely protected from heat loss.

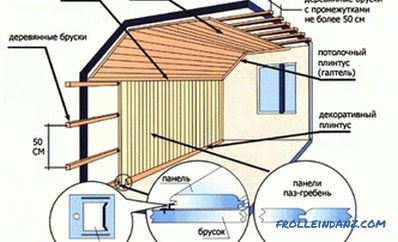

Scheme of thermal insulation of walls with sawdust.

Modern experts in the field of construction began to resort to proven, but undeservedly forgotten and long-known methods of thermal insulation. One of these methods is to heat the floor with sawdust, as well as to ceiling ceilings.

What are sawdust and how are they?

Sawdust is a fine dust that is the result of the process of sawing wood. Often sawdust is called wood pulp, which looks like ordinary dust. In addition to such light and fine wood pulp, one more type of wood production, such as chips, can be used as a heater. The differences between these two types of insulation material consist in the methods of their manufacture, because the tree is planed or drilled for cutting, and not sawed. There is a significant difference in size.

In addition, sawdust may have a different fraction, this value usually varies from 3 to 30 mm, and the length depends on what process the material is and the tool with which it was mined.

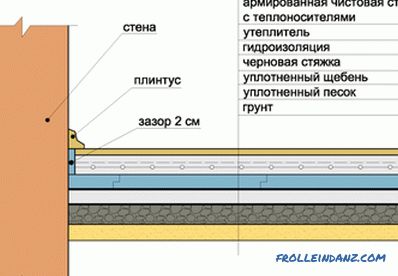

Floor heating scheme with sawdust.

Such a heater is environmentally friendly and has many advantages, including low cost material. The most significant properties of sawdust - sound absorption, thermal insulation and low weight.

Ceiling insulation is a necessary procedure for private buildings, regardless of the material from which the roof itself is made. The fact is that the biggest heat losses are attributed to the ceiling, this figure amounts to 20% of all possible ways of heat loss. A thick layer of insulation from sawdust is probably the cheapest way to insulate the roof.

It is clear that it is quite difficult to lay such material on the floor, but nothing is impossible, and if you make some preparatory measures, no problems will arise. Preparation is to protect against the occurrence of a fire, because wood is inflammable and flammable.

Tools and Consumables

To begin the creation of the insulation layer, you should prepare everything you need:

- sawdust made of wood with small and large elements;

- binder, clay, sand, cement, etc.;

- boric acid, copper lime or vitriol;

- drywall or other breathable coating to create a substrate;

- assembly foam;

- construction sealant;

- protective agents (antiseptics, water repellents and flame retardants);

- construction stapler with a set of staples.

Pre-treatment of the floor

Tools for insulation.

Often the construction of floors is carried out from materials that are pretreated with antiseptic and antifungal agents. But if at the construction stage such treatment was not made, then it should be done before installing the insulation.

Surface treatment is carried out in the following sequence:

- Antiseptics are means that protect the wood from microorganisms, rotting processes and insects.

- Protective equipment gives the structure increased resistance to fire and high temperatures.

- Water repellents are agents that impart water repellency to the coating and do not prevent the excess moisture present in it from being removed from the wood.

Before application, check the compatibility of the products selected for such treatment.

Substrate and features of its application

After the roof treatment has been done, the next part of the work begins, related to laying the substrate, which consists of the following steps:

Table of characteristics of materials for insulation.

- Sealing of joints, joints and cracks on the surface with foam and acrylic sealants. Foam is used to fill the largest defects, small cracks are filled with sealant. Foam work, of course, is convenient, but you should not use it alone, as it is a highly flammable material, and complete with sawdust can increase the fire hazard of the coating.

- In addition to the gaps in the coating, all holes must be filled.Such measures are used to prevent moisture from penetrating into the layer of insulation or so that the draft does not cause a rise in the insulation.

- When the foam hardens, all its protruding parts need to be cut off flush with the surface. Otherwise, it is these pieces that will become the path for the penetration of cold air.

- Next, a substrate of breathable vapor permeable material is created. Cardboard can play the role of such material, as long as it is not wet.

- The installation of the substrate is overlapped to prevent the ingress of sawdust between the seams.

- Joints are fixed with a stapler, staples seizing all layers of the substrate.

- Along the perimeter of the substrate they pass with the help of construction foam or sealant.

The choice of material and its laying

Sawdust to create insulation should be dry or slightly moist, have only a woody scent.

The best option is if the insulation is pre-treated with antiseptic and flame retardants. When the material dries out after this treatment, the lime is added to it in the amount of 10% of the total mass. You should add borax and vitriol and mix thoroughly the mass for a uniform distribution of additives.

Now that the material is ready, it's time to think about how to assemble it. There are two methods of installation:

- Sawdust can be filled up in a dried crumbly form - dry insulation.

- Sawdust is mixed with cement and water - wet insulation.

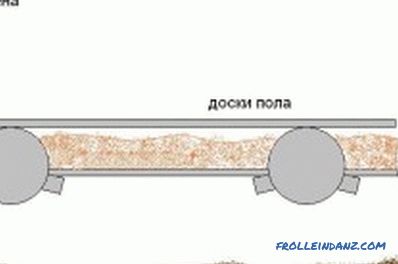

To implement this method (dry insulation), it is recommended to lay the insulation in two layers, the first layer is a material with components of greater size, and the second - with smaller elements. This is important due to the fact that large sawdust is difficult to tamp, and in order for thermal insulation to be of high quality, it is simply necessary.

A layer of coarse fractional material is filled with a width of about 15 cm and carefully compacted. After that, fine sawdust is placed directly on it and is also pressed, compacted with special care. For better tamping material can be slightly moistened.

Thermal conductivity coefficient of opil.

For the realization of wet insulation, wood-shaving waste is suitable, having a shelf life of more than a year, but without fungi and mold. Cement and water in a ratio of 20/2/3 are added to such sawdust. The solution should be made in small portions due to the rapid hardening of the cement. Usually, the creation of a batch begins with the mixing of sawdust and cement, into which not immediately, but gradually pours in liquid.

Pre-shavings should be processed as in the dry method, adding vitriol and fluff to it.

The prepared solution is poured into the space between the roof beams on the substrate or sand. After that, the coating is compacted to a thickness of 8-16 cm.

Floor insulation: recommendations

Thermal insulation of floors with sawdust material allows you to create an environmentally safe, thermal insulation coating, which is also financially beneficial the house has a warm, cozy atmosphere. The set of materials needed in the work, and tools for floor insulation is exactly the same as for the insulation of the ceiling.

As in the case of overlappings, floor insulation is a procedure that begins with the processing of sawdust. For this purpose, the following materials can be used in this case:

- hydrated lime;

- lime-pilonom lime;

- a set of special agents (antiseptic + fire retardant + water repellent);

- lime and glass fragments.

The main difference between floor insulation and ceiling insulation is that when this surface is insulated, shrinkage of this layer is unacceptable, so care must be taken in advance. It is for this reason that the floor is insulated with non-flowing sawdust, and mixtures, which eventually lead to hardening of the material. The main component of such solutions should still remain sawdust. For the preparation of such material used cement or gypsum flour. The recommended proportions of ingredients of the solution are wood material 85%, dry gypsum flour 5%, lime 10%. To prepare the solution should be in small portions, as the plaster seizes much faster cement, which, by the way, it can be replaced.

You can check the readiness of the solution by hand: if, after compressing the solution in your palm, it does not crumble and does not spread, but holds its shape, then it is time to transfer the mass to the surface of the floor covered with the substrate.

After the solution is transferred, it is carefully tamped down, providing the insulating layer with a height of about 25 cm. After tamping, the mass should dry out for several weeks.

Sawdust is an excellent thermal insulation material that has found wide use in construction as insulation for residential houses or even for household use.Such popularity is achieved due to the fact that sawdust combined such parameters as low cost, environmental safety and excellent insulation performance. They can easily and permanently carpe roofs, walls and floor coverings, both in dry form and in various solutions. Provided that the builders will correctly follow the technology of applying such insulation, it will for many years demonstrate excellent sound-absorbing and thermal insulation characteristics.

Didn't find the answer in the article? More information on the topic:

-

How to handle a tree in the bath?

What is the way to process a tree in a bathhouse so that it lasts longer, and it is comfortable and pleasant to be there? We will try to consider the main features and nuances.

-

The better to process the wood from moisture

How to treat wood from moisture. Useful tips and tricks, basic characteristics of impregnations and materials, design features, nuances. Advantages and disadvantages of impregnation.