When during repairs, it is the turn of facade insulation, it is inevitable that it becomes necessary to select a material suitable for this purpose. A modern construction market is able to offer a variety of options and it can be difficult to decide. However, it is worth knowing that there is a material that is suitable in most cases. This material is foam. It has good performance and is quite simple to install. Nevertheless, the question of how to properly conduct the facade thermal insulation with foam plastic does not require a separate consideration. This will be discussed further.

Material description

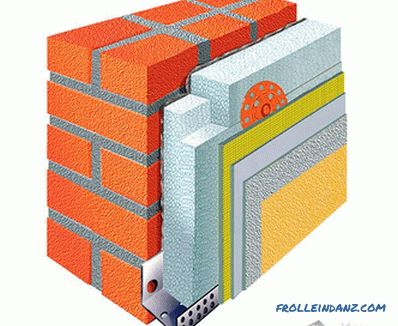

It should be noted that the essence of thermal insulation is to protect the room from free air circulation. As a result of the work done, the cold will not penetrate inside the room, and the heat, on the contrary, will linger inside. Polyfoam, due to its structure, is just perfect for this purpose. It has the following properties:

- It has a very low weight, which means it will not exert additional load on the walls and the foundation.

- Does not require the use of special tools or technology, which reduces the cost of work.

- Immune to water.

- Mold does not form on the foam.

- Material is easy to work with.

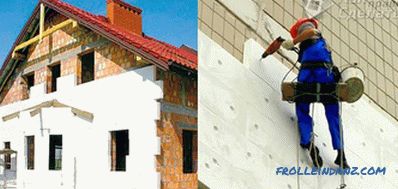

Polyfoam is widely used for insulation

Polyfoam is widely used for insulation

In addition, the material is quite common and relatively cheap , easy to install, making it affordable for a wide range of consumers. The listed qualities are characteristic for the material in question and make it possible to speak of it as a very acceptable option for most cases.

In order to fully understand how to warm the facade of the house with foam plastic, it is important to know that it is best to divide the work into several separate stages and carry out them alternately. This approach will allow not to miss important moments and to carry out all the work at the proper level.

Preparation

Removing old paint before weatheating

Removing old paint before weatheating

Start, as always, better with training. Here we have in mind not only the purchase of the required amount of material and tools, but also the preparation of the surface of the walls of the facade for installation. The fact is that insulation of foam plastic requires compliance with a set of mandatory rules, one of which is the maximum flatness of the surface. If there are any bulges on the walls, such as slurry of mortar or protruding fasteners, they must be removed without fail. If there are defects of the surface of the reverse nature, that is, cracks or dents, then they must be puttied without fail. It is also important that the surfaces intended for the installation of insulation should be treated with a primer for better adhesion of the adhesive solution used during installation.

Installation of foam plastic

When all the preparatory steps have been completed, you can begin to install the insulation. It is best to carry out the work as follows:

- First, it is necessary to note the bottom line, along which the lower edge of the first row of foam slabs is to be oriented. To do this, screw the screw on one side of the wall, and screw the second one on the other side of the wall on the same level with the first one, after which, for clarity, connect them with a cord. Horizontal must be controlled by level.

- Then the starting L-plank is fastened along this line, which will serve as a support for the lower and subsequent rows of the foam.

- Next, you can begin to mount the foam plates themselves. To do this, they applied a special adhesive composition. It is prepared in accordance with the instructions and applied with a simple spatula.

- The lower row of plates is installed on the starting bar. Starting from the edge of the wall, put the first element, next to it the second, and so on.

- The second row of plates is mounted on top of the second in staggered order, as is usually the case with brickwork. All subsequent rows fit the same way.

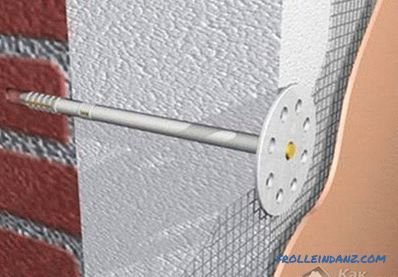

- For additional fixation of foam plates, special fasteners with wide caps, resembling umbrellas, are used. The number of these elements is calculated from the ratio: one umbrella per square meter of surface. To optimize the process, elements are driven in at the joints.

In the manner described above, the entire surface area of the walls is trimmed. As can be seen from the above material, wall insulation with foam plates is of particular complexity. To cope with the work is quite possible on their own.

Finishing

Finishing

For greater clarity and easier understanding of the nature of the work, you can additionally read the corresponding video on subject under consideration.

Video

This video shows how to glue foam, apply a reinforcing layer and plaster insulated walls for painting:

Photos