Experts agree that it is not necessary to lay laminate (even if of the highest quality) directly on the concrete. They argue that plywood under the laminate must necessarily be attached. Laying plywood is needed not only as a smooth base, but also to improve the damping and insulation properties of the underlying floor covering. It is necessary to consider the process of laying plywood under laminate, what it is and what you should focus on during installation.

Laying plywood for laminate.

Laying plywood: preparatory activities

Plywood for laminate should be laid on an exceptionally smooth and clean base. With the participation of the primer close up all cracks and grooves. Then plywood is laid according to the following rules.

Rules for laying plywood under the laminate:

The plywood sheet is fastened with screws or nails at a distance of 15-20 cm.

- Plywood sheets have standard dimensions. Most often the sheet has the shape of a square, the side of which is 1.5 m. Therefore, the sheet is cut into 4 equal parts. A multi-part substrate will increase the number of expansion gaps. And they, in turn, will help eliminate the deformation of the floor in the process of further operation.

- Clearances should be performed as responsibly as possible, since maximum accuracy should be adhered to. The distance between the wall and part of the plywood must be maintained within 8-15 mm. No less and no more. When laying adjacent parts of a plywood sheet, care should be taken to ensure that the distance between them is at least 5 mm.

- It is mandatory to purchase a two-component adhesive composition or water dispersion based on PVA when purchasing plywood. It is needed in order to attach the sheets to the screed. In addition to the glue, the sheets are also attached with screws. It is important to ensure that the caps of the screws do not bulge above the surface of the plywood. Otherwise, the duration of the laminate will be much reduced.

- It is necessary to achieve an even distribution of the adhesive composition under the entire surface of the plywood sheet. Checking the opposite is very simple: this is done by tapping on the substrate. If a characteristic thud comes from all places, then the sizing is made according to the rules.

Sequence of actions for laying the substrate

So, you need to learn more about how the plywood is being laid at all stages of installation. Then it will be possible to make sure that this is a simple procedure and it is quite possible to cope with it without seeking expert assistance. It is necessary to understand one thing: too uneven floor should be leveled with a concrete screed. Otherwise, all efforts on laying the substrate will be reduced to zero.

First, a concrete screed is made. First of all, a special self-leveling compound is applied to the surface, which is neatly smoothed. Such a composition tends to dry out. Experts recommend to allocate about 45 days for this event. After that, a waterproofing layer is laid over the entire surface of the screed. Often the role of this layer is played by ordinary polyethylene, which is joined together by adhesive tape at the joints.

Laying scheme for plywood substrate.

It is also recommended to check, before directly laying the plywood, whether the standard moisture level on the screed is exceeded.

The film is placed on the screed and with the maximum tightness attached at all ends, while the center is left free. If after some time no condensation is found in the center, then the plywood sheets can be safely laid.

Next is the processing of plywood sheets.

Sheets are recommended to be laid in brickwork order. This will make it possible to eliminate the situation in which 4 seams converge at one point.

Then the plywood is cut. Cutting plywood sheets into small-sized squares is performed in order to eliminate the influence of moisture and thermal changes on its characteristics. The best choice of plywood sheets is birch.

Cleaning and priming the base

Before installation, the sheets are thoroughly cleaned from small rough edges.

Some primer them with mastic glue. 12 mm plywood is the perfect choice.

Plywood is laid as follows. Special adhesive mastic of 2 mm is evenly applied on the base. Sheets are laid on it. Additional mounting is carried out using screws or dowels.

Grinding of plywood is the final stage, during which the plywood is polished, in order to get a perfectly aligned surface for the final and last layer - laminate. Grinding is performed in most cases with an ordinary grinding machine or manually using sandpaper with large grains.

Despite the fact that plywood is laid under the laminate, it would seem easy, this process is actually quite laborious and cannot be neglected.

Didn't find the answer in the article? More information on the topic:

-

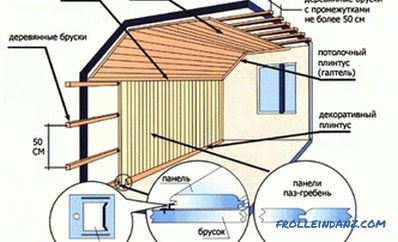

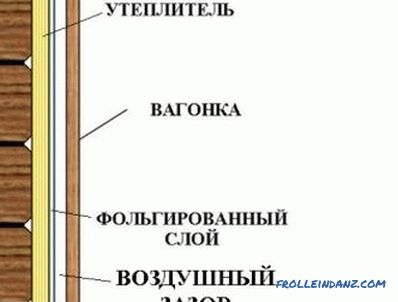

How and how to sheathe a house from a bar with your own hands ?

Recommendations on how to sheathe a house from a bar. Use of vinyl siding and wall paneling, block house and metal siding, fiber cement and thermopanels. Tools required for plating.

-

Which is better: plywood or drywall?

So what is better, plywood or drywall, those who come across materials for the first time ask themselves the question. Both of these materials are quite economical and are used almost always.