Arrangement of a plot near a private house or cottage can include landscape planning, planting plants and a lawn. Additional buildings are also an integral part. Great to have a cozy place to relax and rejuvenate. An octagonal gazebo with your own hands will allow you to take a breath and enjoy eating in the open air. Such a solution boasts a good capacity, which will invite best friends.

Reasons for choosing

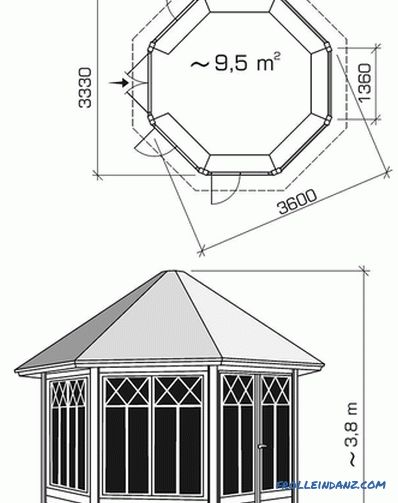

The octagonal structure allows you to comfortably accommodate all those present: communication will be more pleasant, because everyone will be able to see any of the interlocutors. If a table of the same form is located inside, then up to 15 people can be placed behind it calmly. At the same time during the meal, no one will interfere with his neighbor. With proper design and selection of materials it can be used at any time of the year. Even with a minus temperature inside you can feel quite comfortable.

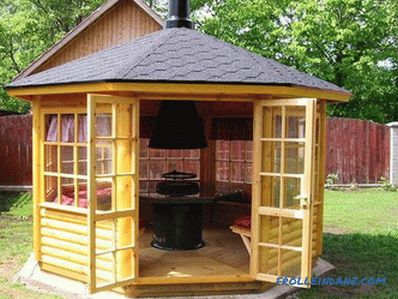

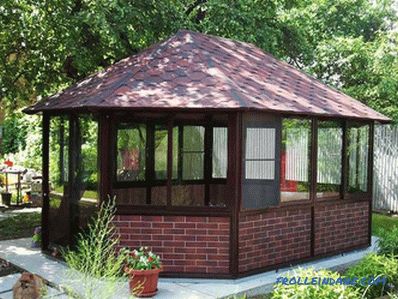

Closed octahedral arbor

Closed octahedral arbor

The shape of the roof follows that of the whole structure. This means that the structure will have several ramps. Even if the area is famous for significant rainfall in the winter, it will not be a problem, because the reference points are located in such a way that they can withstand a considerable load. Also, he simply will not be able to linger for a long time. If you foresee an overhang of sufficient size, then rainwater will not be blown into the middle by the wind.

Octagonal roof

Octagonal roof

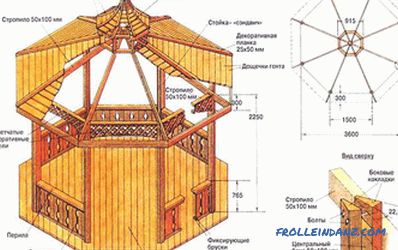

Implement such a project is possible even for one person without additional help. It is much easier to do this if you have certain skills in working with power tools on wood or metal. In any case, there will be an advantage to improve them in the process of moving the case. The key to success is thoughtful initial planning. In this regard, there is no way without a good drawing. It will need to be applied to all sizes. It is better to perform the image in several planes. This will allow to take into account even the small nuances of finishing.

Choice of place

It is good if the gazebo is surrounded by lush green plants. When there is a small garden near the house, it will be an ideal place. Place the product as far as possible from the main structure, this will allow you to completely immerse yourself in silence and get away from the everyday hustle and bustle. There are a few more nuances that will help determine the ideal option for construction:

- Is it planned to have running water near the gazebo or in it. Guided by this factor, it is necessary that communication be within reach. If there is a well nearby, water can be brought manually or a pumping station can be installed and additional pipes can be made.

- The plot should be relatively flat. This is not a requirement. In principle, such a structure can be erected on the territory with any allowable slope, but there will be certain difficulties in order to ensure the same level of support.

- Choose an area that cannot be washed away by groundwater, as well as one where rainwater does not stagnate. It is very important that the implemented project lasts as long as possible. After all, the gazebo is not made for one season.

- It is better not to place the building close to the edge of the plot. This will be inconvenient for both those present and neighbors.

- Carefully review the land act. Usually it indicates which territory in the area is intended for. If these conditions are not met, the relevant services are entitled to fine the owner or dismantle the fruits of the works.

Arbor in the shade of the garden

Arbor in the shade of the garden

Depending on the openness of the area, you can plan how there will be arbor walls. Is it necessary to close them completely or will there be enough a fine mesh that will block the flow of air, and the rest will be compensated by the surrounding plants.

Foundation

A summer house is not a house, therefore the choice of the base is wide enough. Everything will depend on what kind of soil in a particular area, as well as what the planned budget. We will consider several basic options that can be realized by our own efforts without the help of a specialist. But the most important point at this stage is the markup. Much prettier when the whole structure is produced with equal sides. If there is a desire to achieve just such a result, then it will be necessary to do the following:

- Grass mows in the chosen territory. It can interfere with tightening the fishing line or twine.

- The square is being marked. Its side should be equal to the total length or width of the future arbor. It is very important that he has all the angles at 90 °. For this, 4 pegs are driven in. Between them diagonals are checked. They must match. If this fails, then one or more elements must be moved to achieve this result.The fishing line or string, which forms a regular geometric figure, is stretched. If desired, the resulting angles can be checked with the help of the construction angle.

- Each side is divided into three identical parts. At these points is hammered by a peg. A total of 4 pegs on one side.

- Now the task will be to connect the pegs which are clogged in the middle of each side. This must be done in such a way that it is a square with beveled corners.

- If everything was done correctly, then all 8 sides will be the same length. The first 4 support pegs with the fishing line, which is stretched between them, can be removed.

There is one more way that will allow to implement such markup:

- A peg is driven in the middle of the designated area.

- A rope is tied to it. Its length should be equal to the total length of the future structure. She should be worn so as to quietly move in a circle.

- A peg with a pointed end is tied to the second end and a circle is described.

- The next step is the diameter through the circle. To it is perpendicularly held another. To the second the next one and so everything should be four. The resulting points are interconnected and the correct octagon is obtained.

If the task is not that all sides are the same, then you can choose to what extent the corners of the square or rectangle should be cut. But when there is symmetry, then the whole structure looks much neater.

A pile foundation can be made in a few hours if the supports themselves are purchased ready-made. Definitely this option will cost a little more. If the farm has a pipe of 50 mm and small sheet metal residues with a thickness of 5 mm, and there is experience in working with a grinder and welding machine, then everything can be done from scratch.

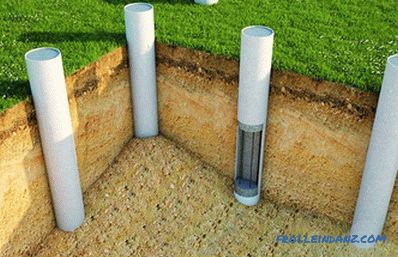

Arbor on screw piles

Arbor on screw piles

- In total, you need 9 elements. In each corner there will be one pile, another pile will be screwed in clearly in the middle.

- The same segments are marked and made. In order to determine their length, you need to know how deep the soil freezes through. If this value is, for example, 70 cm, then the total length will be such that the main screw is immersed 15 cm below this level, and there are still 15 осталось20 cm above the surface. The result is approximately 1.2 m (this is so it is necessary to take into account the length of the tip, which is located before the screw).

- At one of the ends it is necessary to make a pointed tip. To achieve the realization of such a form, it is necessary to make cuts to a depth of 15 cm. They must be made in the form of triangles with the top pointing upwards. After that, they are bent in the middle to make it look like a pyramid. The resulting joints are boiled by a welding machine. The seams are well cleaned and sanded, so as not to create difficulties when diving.

- Making the blades will be one of the most difficult tasks. Blanks for them can be purchased, so as not to suffer. If this is not possible, then suitable sheet material, as mentioned above, or disks from tractor harrows. A circle with a diameter of 30 cm is cut. A hole is made in the middle, it must be calculated so that the tube can easily go into it. Then a cross section is made from one side to half. The parts are bent in such a way that a spiral is obtained. Her step is 50 mm. The resulting construction is welded to the pipe. All seams are also carefully processed.

- Step back 10 cm from the opposite end of the pipe and drill a transverse hole. Its diameter must be such that it fits the element that will be used as a lever.

- Each element is cleaned, coated with an anti-corrosion compound and painted. This is done to ensure that the metal lasts as long as possible, being in the wet ground.

- One element is twisted into each of the marked points. In order not to drown them too much, it is necessary to put labels to which the immersion will be carried out.

- Each of the supports must be supported in a vertical and horizontal plane. This can be done with the usual level, which is vertically mounted on the support. During the operation, it is necessary to control the position of the bubble inside.

-

Pile with welded head All protruding tips are aligned in height. To do this, you can immerse some part more or make trimming. To check the height, it is necessary to select a reference point and measure from it using a water level or a normal level of suitable length.

Pile with welded head All protruding tips are aligned in height. To do this, you can immerse some part more or make trimming. To check the height, it is necessary to select a reference point and measure from it using a water level or a normal level of suitable length. - The next step is to make the base for the grillage. For this, squares with a side of 20 cm are cut from sheet material. They are welded onto the upper end.

- The internal area must be properly organized so that water does not accumulate under it. For this, sanding is made in the form of a cone from the middle, so that it diverges towards the edges. It is well rammed, on top several sheets of roofing material are laid with overlap.

If there are no such materials on the farm, and you need to get by with minimal expenses, then you can go another way. But it is important to take into account that the condition of the soil should be such that the upper layers do not shift when wet.

Foundation of blocks

Foundation of blocks

- Markup is made as described in the previous case.

- In each corner a hole is dug to a depth of 50 cm, its dimensions are 45 * 45 cm.

- A layer of 20 cm is filled with sand. It must be very well compacted. After that, it can be moistened, added to the level after shrinking and rammed again.

- Another 20 cm of crushed stone is laid and is also well rammed. The remaining 10 cm are covered with sand.

- Two blocks fit on the formed pillow (elements with dimensions of 20 * 20 * 40 cm will fit). They must be very carefully set, since subsequently they will serve as a reference point for the rest. They are strengthened among themselves with the help of mortar.

- Using a water level or rule in the same way, two stones are set at each corner.

- The next step is to lay two more blocks perpendicular to the first one. All elements must also be in the same horizontal plane. It is very important that then the whole arbor does not get skewed.

- The interior is laid in the same way as described above.

T. Since this option is not suitable for every territory, there is a solution that will be much more reliable.

Formwork for a bored column foundation

Formwork for a bored column foundation

- The site is marked.

- Pits are dug at 9 points. Their width and length can be 50 * 50 cm, but the depth should be such as to pass the level of soil freezing.

- The walls are aligned, the bottom is rammed.

- The same bedding is made as described in the previous case, but the layers should be 15 cm thick.

- The formwork is installed inside. It can be made from plywood sheets or from a regular edged board. If the board is small, then it goes off into shields. Walls must be placed to withstand the level.

-

Scheme of the columnar foundation The metal frame is laid. In order not to knit it, you can simply insert a few rods of metal fittings with a diameter of 12 mm.

Scheme of the columnar foundation The metal frame is laid. In order not to knit it, you can simply insert a few rods of metal fittings with a diameter of 12 mm. - The solution is poured inside and compacted well with a vibrator. It is important that all the columns get the same height.

- After a few days, the formwork can be dismantled. But until a full set of strength will need to wait 3 weeks.

- Around the resulting columns the space is covered with sand and is well rammed. Additionally, they can be wrapped waterproofing in the form of roofing material or bikrost.

Brick arbor on slab foundation

Brick arbor on slab foundation

Another base variant that can be taste - slab. To implement it, no more effort is needed than for the previous ones, but it is not inferior in strength, and in some moments wins.

- An octagon is applied to the territory.

- Over the entire area, excavation is done to a depth of 30 cm.

- Filling is done as described above.

- The plane is aligned.

- Exposed wooden formwork in the form of a future arbor.

- A metal crate of reinforcement rods fits inside a small trench. It can and not do bulk. It is enough to lay the segments on the supports so that they form a grid.

- Filling of the prepared concrete is made. He is well rammed and compacted.

- If the formwork was level, then it can be used as beacons to level the screed. You will also need a long rule or profile for drywall.

- An additional assistant will be a vibrating rail, if you can hire one, it will be great, it will allow you to compact the layer to the desired consistency. If such a tool is present, then less water can be added to the solution, which will speed up its setting.

- A month will pass before it is fully frozen. During this time it is better to do nothing. To a certain extent, shrinkage occurs, it can lead to damage to the whole structure, if it is erected ahead of time.

- Do not allow the stove to dry. Periodically, it should be wetted, it can also be covered with slate or other material, which at first should be protected from direct sunlight. With rapid loss of moisture cracks appear, which is not good.

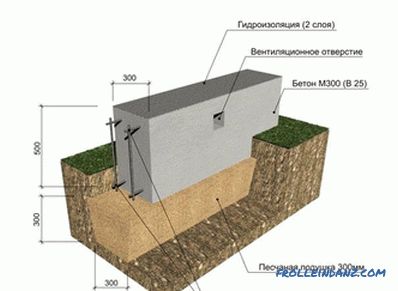

Scheme of shallow strip foundations

Scheme of shallow strip foundations

The last option would be a classic non-buried strip foundation. He will have to tinker with a little in terms of formwork, but the result is worth it.

- Markup is made. But in this case it is better to take another step that will simplify the bookmark. At a distance of 15 cm, it is necessary to make another octagon and stretch the line along the perimeter. So get two figures, between which the excavation will be carried out.

- The trench is dug to a depth of 30 cm in two layers, filling of sand and rubble is made.

- The next step will be formwork. Its separate parts need to be made according to the size of each of the faces, in which case everything will turn out as it should.

- It can be strengthened with the help of strings, which at one end will rest against the formwork, and at the other end a hammered peg.

- It is important to observe the horizontal and vertical angle of the plane.

- Inside the metal crate or construction bottle.

- All contents are poured with concrete solution.

- The top is pulled down and pulled out so that later the racks can be on the same level.

- The care of the finished foundation in the first stages is the same as described above.

If tile laying is not planned on the base plate, then the surface can be made more attractive. To do this, you must still sprinkle fresh mortar with dry cement and gently walk with a batten. Thus, the so-called ironing process is carried out.

Wooden arbor project

Open octahedral arbor with steps

Open octahedral arbor with steps

Those dimensions that will be given in the solution described can be taken as basic ones or proportionally increased in accordance with the territory planned for development. To perform the work, you will need the following tools:

- miter saw;

- hand circular saw;

- square;

- level;

- tape measure;

- stepladder;

- screwdriver;

- fastener material;

- belt grinder (optional)

- marking tool.

From the material will be needed:

- a bar with a size of 10 * 10 cm (or 15 * 15 cm);

- edged board 10 * 5 cm (or 15 * 5 cm);

- board for sheathing under the roof (purchased for specific material);

- roofing material.

Drawing of an arbor

Drawing of an arbor

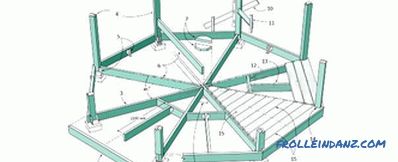

All work must begin with floor installation. This is important so that it will be convenient to move around when mounting the remaining parts. For the foundation of blocks, piles and columns, the sequence of works is described below.

Mounting of the grillage . This is a wooden base that will connect all the supporting elements to each other and become the starting point for the entire structure. If a rectangular structure is mounted, then there is usually no particular difficulty, but in the case of this option, you will have to sweat a little. 8 pieces of a bar are prepared. Their size should correspond to the length of one of the faces plus an overlap of 5 cm. With the help of an end saw, the edges should be cut to an angle of 22.5 °. If this is done with a regular hacksaw, then the calculation can be made as follows. When the size of the beam 10 * 10 cm at a distance of 10 cm from the edge of the line is drawn. If you look from above, you get a square. In this figure it is necessary to divide the lower side into 2 parts and lower the line to this mark from the upper corner of the end face. This will be the required angle. It is very important to observe it so that the whole structure can be well joined. You can connect all the elements together by half the joint. To do this, each of the timber is made on the edge of the notch on half of its thickness and width, which will lie the next element.

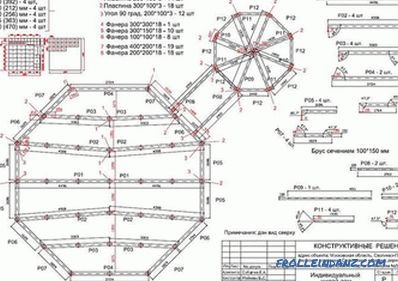

Drawing of an octahedral arbor

Drawing of an octahedral arbor

Fasten them better with hex head screws (" wood grouse "or HEX).

Before placing the base on the concrete structure, it is necessary to lay waterproofing. Roofing material or bikrost is used for this. They are necessary so that the moisture from the supports is not transferred to the wood and it does not rot. Fixation is carried out using bolts to the metal or anchors to concrete. In this case, you need to be careful that the fastening material does not get into the screws, which fastened the grillage.

Mounting the grillage on a column base

Mounting the grillage on a column base

Installing the lag. For the supporting elements in this case, boards will be used for the thickness of the grillage. You can install them in two ways. Everything will depend on how the pattern will be followed by the next flooring. If it is just an edging board that will be laid parallel across the whole area, then the easiest option will do. For this, 8 elements are set from each face to the middle.In this case, they can be fixed to the grillage through with screws or metal corners. All of them converge to the middle, stacked on the central beam or post, which were provided for these purposes. After that, they are connected by curved metal straps from the inside. If laying will be carried out in a circle, then you have to complicate your task a little. All the same 8 elements will be laid, but they will be fastened to the wooden base at the corners. In order for the docking to be at the highest level, then along the ends it will be necessary to make cuts in the shape of an isosceles triangle, the upper angle of which is 45 °. At the same time he fits perfectly on the corresponding in the grillage. Fastening is carried out using metal corners. In the middle of the beam are reduced in the same way as described above.

The frame of the frame

The frame of the frame

Additionally, a jumper is made approximately in the middle of each leg, it connects to the corresponding side of the base with another piece.

In another embodiment, you can not suffer from the gash in this way. But for this, at the stage of building the foundation, it is necessary to provide additional supports. They will need 3 in the middle of the structure. If this was provided, then it will be possible to install three parallel lags between two of the sides of the octagon, perpendicular jumpers are mounted to stiffen.

The surface is being laid. If this is a circular solution, then each bar from the ends must be cut to an angle of 22.5 °, in which case they will be perfectly joined and a beautiful shape will be obtained. In the case when the boards are laid in parallel through the whole space, then after the installation is completed, they must be cut so that they are flush with the grillage. You can fix them with screws on wood or nails to the logs that were mounted before.

The floor for a variant with a slab foundation can be made later by laying tile or other flooring. For a tape base, you can tamp the entire space inside with sand. But this should be done not to the top, but with a gap under the laying of paving slabs. It is located inside, and the walls of the base serve as a kind of stops that prevent spreading.

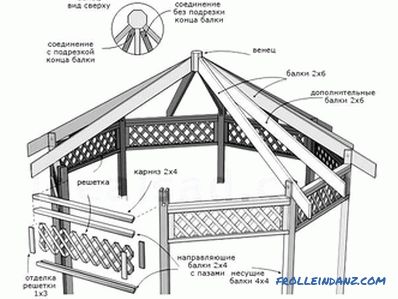

There is no point in finishing processing at the moment, since the main work is still to come. The next step is the installation of the frame:

- 8 racks are made from the timber that was used for the base. Their height should be such that a person can enter the middle without bending their heads. For example, this value could be 2 m.

- They are set at 8 angles. It is better to fasten them to the grillage, therefore in the places of junction it will be necessary to make cuts of the laid board for the floor. Fixation is carried out using metal corners. For greater strength, spike joint can be made.

- Each rack is set in a vertical plane. To do this, use the normal construction level, it must be attached to the beam and move it until the bubble is in the middle. To temporarily fix it, you can use oblique supports, which are made from scrap materials.

-

The rafter system of the octahedral roof The top trim is made. There are several ways to do this. For example, the same edging board is used as for the lag. At the same time they are fixed in two lines from the outer and inner side. It must be remembered that individual parts should go in until the middle of the beam so that the adjacent plank has its place for fastening. In another embodiment, you can apply the same bar as for the grillage. At the same time, the length of each side must be such that a part of it goes on the end and between the two adjacent planks there remains a space in which the rafter foot will be laid. It will not be a problem if the two beams dock at an angle of 22.5 °, and you can already lay the rafter leg on top. Another way is to make two parallel strips with a small distance from each other. They are mounted end-to-end or lap with racks. Between them, it will be possible later to make a decorative wooden crate.

The rafter system of the octahedral roof The top trim is made. There are several ways to do this. For example, the same edging board is used as for the lag. At the same time they are fixed in two lines from the outer and inner side. It must be remembered that individual parts should go in until the middle of the beam so that the adjacent plank has its place for fastening. In another embodiment, you can apply the same bar as for the grillage. At the same time, the length of each side must be such that a part of it goes on the end and between the two adjacent planks there remains a space in which the rafter foot will be laid. It will not be a problem if the two beams dock at an angle of 22.5 °, and you can already lay the rafter leg on top. Another way is to make two parallel strips with a small distance from each other. They are mounted end-to-end or lap with racks. Between them, it will be possible later to make a decorative wooden crate. - Selects the angle of the roof. It can be in the range of 20‒30 °. Determined by the height to which you want to raise trusses relative to the upper trim.

- 8 identical elements are cut from a board of 10 * 5 cm or 15 * 5 cm. Their length must be such that it closes in the middle according to the selected angle and also protrudes 20-30 cm beyond the edge of the building, which ensures rainwater runoff without getting into the gazebo.

- It is necessary to make an octagon from a bar. The length of its side should be equal to the thickness of the board for the rafters, and the height should correspond to the width. This element is very necessary, becauseit will provide an opportunity to join all the supporting elements of the roof in the middle and securely fix them among themselves.

- At this stage, you will need an assistant who will be useful in holding the jumpers for the roof when they are mounted. At first, the element is applied and one part of it rises to the required height. There is a corner on which it will be necessary to make a gash in the place where the rafter will be adjacent to the rack. According to this pattern, cuts are made on all components.

- Fastening to strapping or racks is carried out thanks to the metal corners. Also, metal plates, bent to the desired angle, carried out fixations of all rafter legs to each other.

- The next step is to install the batten. If you plan to make a roof of soft tiles, then the lining under it can be made of waterproof plywood or OSB sheets, which are cut into triangles according to the size of the construction step. Fastening is carried out with the help of screws. The finishing touch will be the final touch.

Wooden arbor scheme

Wooden arbor scheme

Racks for strip and slab foundations are installed directly on the base, without wooden bottom strapping. But for this you will need to provide waterproofing for the columns. Their lower part to a height of 10 cm can be wrapped in bikrost or roofing felt or just make the lining of this material.

Metal arbor project

It is possible that someone will decide for themselves more expedient to build a metal arbor. For this option, you will need a profile tube 50 * 30 mm. The total length, which will be spent on the creation of the frame and stands under the benches will be approximately 100 m, as well as 6 sheets of metal tile. The following tools are required from the tool:

- Bulgarian;

- welding machine;

- tape measure;

- consumables for power tools;

- square ;

- construction level;

- pipe bender;

- drill;

- riveter;

- miter saw on metal.

The design can be installed on any of the types of foundations listed. The manufacturing process will be as follows:

- With the help of the grinder, 12 blanks with a length of 1.25 m are made. They will be needed to create the upper and lower bases. For arched elements, 8 parts of 4.7 m each are cut.

- For each of the 12 blanks, it is necessary to cut the butt at an angle of 22.5 °. This can be done with a miter saw or with a grinder. Angle calculations are made as described for the grillage wooden beams.

- With the help of a welding machine, two octagonal identical frames are made.

- Arched arcs are made with a pipe bender. They need to be made in such a way that flat stands to a semicircle have a size of 1.5 m, and the distance between them is 1.2 m. racks.

- At the base between two opposite sides, two strips of the entire length are welded. Perpendicular to them, two more jumpers are attached, which will ensure the rigidity of the structure.

- Prepared arcs are fixed to the lower octagon. There is a gap of 10 cm between them. It is necessary to make additional jumpers. In their role can serve decorative patterned products from a strip of metal.

- The required roof angle is determined.

- 8 elements are cut, which will serve as supporting strips for roofing. Their upper ends are slaughtered under an isosceles triangle with an angle at the apex of 45 °.

- They are attached to the second octagon and boiled together to form a monolithic structure that will resemble a pyramid.

- The resulting construction is welded to the installed arches.

- With the help of prepared sheets of metal, the roof is sewn up. Holes of the appropriate size are drilled and fastened with rivets. You can use special tile screws with rubber stopper and hex head.

- At the level of 1 m from the base, jumpers are made in the arches. Subsequently, they will serve as the upper support for the back of the bench.

- For the organization of the seats, the sections of the profile tube are perpendicularly fixed to the racks. In order to have additional support, it is necessary to make oblique supports.

Finishing

On a raised base

On a raised base

First you need take care that the material from which the project was made is protected from the effects of various weather conditions. In this case, the metal is cleaned of rust or treated with a special compound that removes it. The next layer is applied primer and finishing paint. With regard to wood, the process will be a bit more troublesome.The entire structure will need to be sanded with a tape or eccentric machine. If necessary, change the shade produced by opening the stain. The rising fibers are ground again. Three coats of varnish are applied. After the first two you also need to go fine sandpaper to improve adhesion.

The best option would be a yacht or other composition for outdoor use.

To be comfortable inside, you need to take care of the benches. Preparation for them must be made even at the stage of erection of the frame. Special supports may be provided, for example, as described for the metallic version. The trimming board for flooring is thoroughly polished, the ends are cut to an angle of 22.5 °. Their size should be such that they lay on half support. They are processed in the same way as the frame. At a suitable height, wood backrests are installed.

It is good if the table will also have 8 faces in shape. This will allow it to fit perfectly into the interior. The optimal width will be the size of 1.5 m. In this case, it will be convenient to reach the middle without additional effort. To strengthen it in the metal version, you will need to weld the frame, and to the jumpers that go along the base, lower the racks. For a wooden structure, you can order a table that will not be fixed inside, but will be a separate element.

Wooden octahedral pergola pergola

Wooden octahedral pergola pergola

The side walls are decorated in any interesting way. This may be a wooden lattice, which is made of boards of small thickness, they are located one in relation to the other at an angle of 45 °. If desired, the bottom can be closed completely to the middle, and in the remaining openings to mount the glass. This will allow to use the building in any weather even with strong wind. To protect yourself from little bloodsuckers, you can cover the entire area with a mosquito net. Fresh air will quietly flow into the middle, but insects will not be able to get inside.

Octagonal glazed gazebo

Octagonal glazed gazebo

In some designs the brazier can be placed inside, but more often it brings certain inconvenience, since smoke can interfere with nearby. To make it much more comfortable, you need to consider an additional platform near the building or bring a separate chimney.

For an evening out, you need to think about what kind of lighting will be in the gazebo. The most economical option are LEDs. In principle, if the roof is made with high quality and does not leak, then a regular lamp or a chandelier will do. But due to high humidity, internal contacts oxidize very quickly. To prevent this, hermetic products with IP67 or IP68 have been developed. They are not afraid of water or dust. The main connection can be made with a double braided cable. This, for example, may be VVG. It is a monolithic copper conductor. In order that it does not sag, it is tied to the cable. There is a type of wire in which the metal cord is already soldered to the outer sheath. The panel should be a separate machine, with which, if necessary, you can de-energize the gazebo. Switches and sockets are selected in tune so that they are not particularly highlighted. They will be outdoor installation. It is desirable that both switches and sockets are also sealed.

With a two-level roof

With a two-level roof

We are sure that we received basic information and guidance on how to build gazebo of this type, you can cope with the task. There are no two identical projects. Therefore, we are interested in what happened in your case and how a ready-made gazebo looks at the site. Share the results of your work in the comments to the article.

Video

Construction of arbors in the process:

Read also:

- How to build a six-sided arbor

- Construction of arbors with a brazier

- How to build a polycarbonate gazebo

- Construction of a live arbor