Laying of floorboard is made on an even and dry basis.

The floorboard deserves people's love due to the fact that it has an aesthetic appearance and is easy to install.

Parquet boards are placed (for 48 hours) in a horizontal position in the room in which installation work will be carried out.

Preparatory work

To check the flatness of the base of the floor, a building level of 2 m is used. The surface is leveled if there are more than 2 mm of irregularities per 2 m of length of the area. The room is settled ventilation. Boards for laying can be unpacked on the day of installation work. Each rail is inspected for defects.

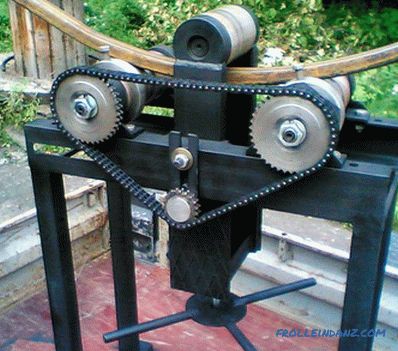

Tools for laying floorboard.

The process of laying floorboard on plywood is performed using:

- a hammer;

- a bar;

- a tape measure;

- wedges;

- saws.

The substrate can be any natural material, including cork mat, plywood. Reiki laid with the parameters of the room. If its sides do not exceed 8 m, then the laying of the floor is perpendicular to the most illuminated window. Otherwise, installation work is carried out along the longest possible wall. Then you need to measure the width of the room. The width of the gap (between the wall and the board) is subtracted from the result. The resulting number is divided by the width of 1 rail. Such a calculation will make it possible to find out how many rows will be required (reduction of the width of the last row).

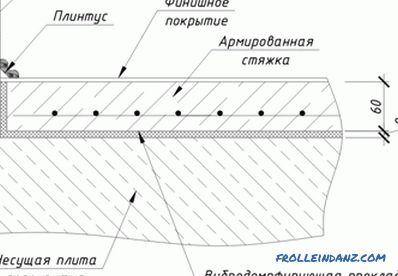

If at a concrete floor the humidity fluctuates within 2-3%, then the moisture insulation of the base is made. For this purpose, a polyethylene film is used, the thickness of which is 0.2 mm. The joints are glued with special tape.

Step-by-step actions

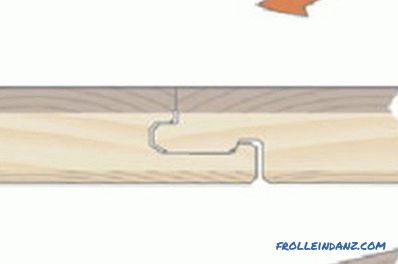

Locking scheme of the parquet board.

The backing is mounted end to end. If pressed chips are used for these purposes, then the panels are placed at a distance of 2 mm from each other (a gap of 10 mm is left between the material and the wall). Initially, plywood is placed on the plywood with a lock spike against the wall. For their compounds used ends. There are several ways to connect the rails:

- spike into the groove - parallel insertion of profiled elements;

- end methods using a hammer and wooden wedges.

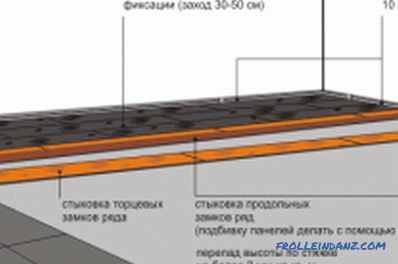

The subsequent rows begin to mount with the help of fragments left over from the previous laid bar (the length of the last element should not be less than 50 cm). The board (at an angle) is inserted into the groove with a spike. The product is squeezed by hand. The next board is laid on plywood by a similar method, while maintaining a gap between the ends of 5-8 mm. In the cracks (near the walls) insert wedges.

The contour of the pipes of the heating system is delineated, cut out of the rails and laid.

If necessary, the boards of the last row are narrowed (from the side of the grooves) to the desired dimensions.

Wedges are removed from the floor. Plinth mounted dowels and screws or rail, which is installed in advance.

The resulting finishing surface is ready for use. The maximum parameter of the floor (without an expansion joint) in width is 8 m, and in length - 20 m. The coating can be used if the temperature in the room varies between 18-24 ° С and air humidity 45-60%.

Installation work

Floorboard flooring scheme.

If the parquet board has no locking connection, then experts recommend it to be laid on glue. A similar technique is used for rails with poor locking connection and the presence of only a groove. Given this technology, it will be necessary to make a primer base. The mixture is applied to the coating roller. When carrying out this work, the formation of large concentrations of primer in the 1st place should be avoided.

The next stage can be carried out in 12-24 hours (after applying the composition to plywood). Adhesive substance is prepared according to the manufacturer's recommendations. The mixture is applied to the coating evenly. For its distribution used notched trowel. The board is laid and strongly pressed to the substrate. Glue should not flow onto the front side of the plank. Subsequent elements are laid and pressed against the previously laid counterparts. The finishing coating will need to be pressed with the help of heavy objects, which must be on the received surface for more than 12 hours after the installation. The surface will be ready for operation after 6 hours.

When arranging the floating floor, certain requirements must be observed:

- more than 60% of the surface of each board is covered with glue;

- the base should to be durable (for tearing - more than 1 MPa, for compression - 25 MPa).

For carrying out the process in question it is recommended to use only synthetic and polyurethane glue, similar mixtures, intended for the installation of a heated floor. Do not use a dispersed composition.

Didn't find the answer in the article? More information on the topic:

-

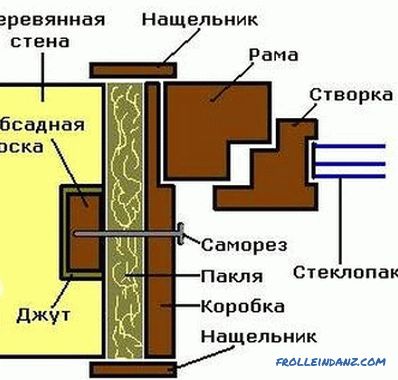

Wooden windows: making your own hands

Do-it-yourself wooden windows: the advantages of installing wooden structures. Varieties of windows from natural breeds. The stages of the manufacture of wooden windows, installation design.