Making furniture from natural wood allows you to equip a room or kitchen with things that are not powerful over time. This furniture will not go out of fashion, will not lose its relevance after the repair and will create a cozy homely atmosphere for many years. Start self-assembly should, having a small stock of knowledge about working with wood and practical skills to work with various carpentry tools.

The advantages of a wooden kitchen include: relevance, durability, environmental safety.

Preparation of the material and the basis of production

In modern conditions, the main components from which a kitchen made of wood will be assembled can be lamellae. These are blanks for making furniture. They are shields of a certain size, dried, processed and assembled from wood. Already finished products can save time and effort for the procurement of the main raw materials for the kitchen. In addition to saving time, the buyer receives reliable, durable moisture-proof products, which is important in the manufacture of kitchen furniture, since the installation environment implies a high load and possible ingress of moisture.

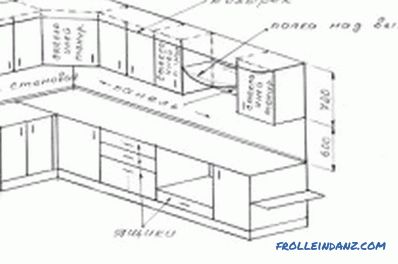

Kitchen scheme with a frame.

If desired, such blanks can be made independently, but this will require a large supply of patience, strength, tools and time. Therefore, the costs will be incomparable with the result.

Before the kitchen is assembled by the hands, it is necessary to draw up a drawing and in the process of preparing the items and assembling, stick to the already outlined scheme. You can make parts on your own or order from a laminated chipboard, fiberboard or plywood company. Since the cost of wood is constantly growing, in order to save wood, you can only make the front side, and the rear and side can be made of high-quality fiberboard or plywood.

The ability to order sawing and processing of all parts significantly reduces the time to prepare the elements, and the lack of high-tech equipment will not affect the speed and quality of processing.

Assembly of the frame

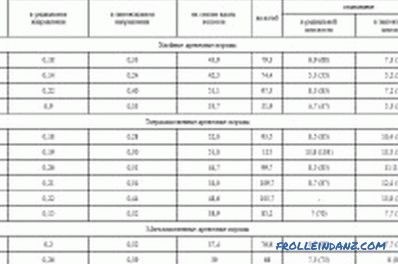

Basic technical properties of various tree species.

Assembling a framework for the future kitchen on their own, use a wooden bar of 50 * 50 mm or any other that fits in size, but no less, since the design should be durable and reliable. All parts are connected by spikes, made on a milling machine or by hand. In the process of assembly, various methods are applied: joining with spikes, by means of an adhesive composition or combined. As the glue used PVA or carpentry, although in recent times its distribution and popularity are reduced due to the lack of components for its preparation. And the technology of its cooking goes into the distant past, and very few people know this secret.

A sign of high-quality and professional wooden furniture is the complete absence of metal connectors. So, the frame is assembled with the help of spikes, glue and selected quarters of a bar.

Elements of cabinet furniture

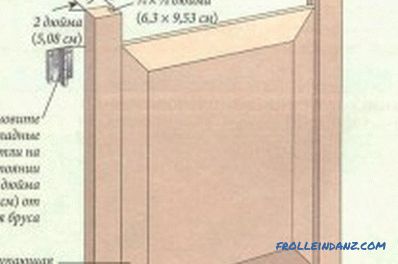

Scheme of manufacturing paneled door of wood.

The back and side parts are fixed on the assembled frame. This may be a wooden lamella, fiberboard or particleboard. Rear wall thickness not less than 15 mm.

However, much more materials are used for facades:

- natural wooden solid wood;

- pressed billets - particle board, fiberboard, etc.;

- aluminum parts and components;

- plastic panels;

- glass parts made of tempered glass, machined on various machines and devices.

Facades are made in the form of framed parts and solid canvases. Internal inserts for paneled doors can serve all of the above materials. Solid facades are made of wood with their own hands, before installation they are treated with antiseptics, varnishes or paints to increase the durability of natural materials. Although coating paints spoils the entire natural texture of the array.

The distribution of natural materials is obtained when it is necessary to fulfill the furnishings of the kitchen in a classic or modern style - modern.

When choosing natural parts for the kitchen interior, you should consider the advantages and disadvantages of this material:

- The advantages should include relevance regardless of fashion, durability, environmental safety.

- The disadvantages should be treated more closely - exposure to direct sunlight can ruin the expensive and high-quality finish, in the absence of care, the tree absorbs and accumulates odors, with time it will emit all the accumulated kitchen flavors.

For the production of wooden facades only expensive and high-quality wood species are used.

The main suppliers of beautiful and embossed textures are ash, oak, cherry, pear, and nut are much less commonly used.

Within the limits of purchasing power is pine. Acrylic paints are very rarely used to protect the facade elements, since they completely hide the natural beauty of the array, very often they apply only a few layers of varnish.

Didn't find the answer in the article? More information on the topic: