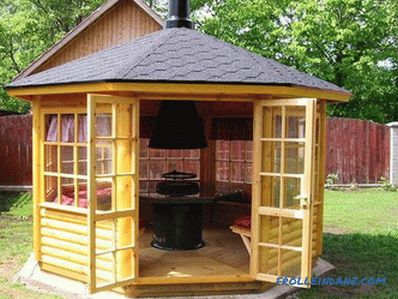

If the question arose of how the floor should be laid in a wooden house, you can prefer the best option - arranging the floor over the surface of the lag. Such a solution will make the wooden construction even warmer.

The construction of the wooden floor along the logs.

The process can be completed by overcoming several stages, the first is the preparation of the base, the second is the installation of the lag, the third is the laying of the heat insulator, in the role of which the mineral wool is often used. The next step will be the installation of boards that act as a clean floor.

Tools and materials

Tools required for work: level, hammer, drill, screwdriver, perforator, electric saw, nail puller.

- level;

- sheet plywood;

- logs;

- heat insulator;

- substrate;

- self-tapping screws for woodwork and having a countersunk head;

- nails;

- anchor bolts (10 mm).

- brick;

- roofing felt;

- hammer;

- ax;

- electric razor;

- saw;

- drill;

- screwdriver;

- nail puller;

- parquet;

- wood;

- punch.

Preparatory work

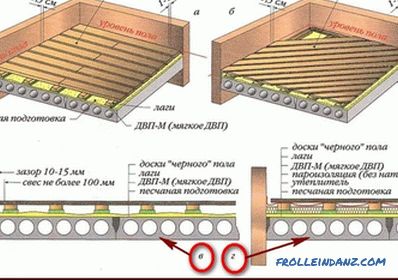

Construction of the sub-floor.

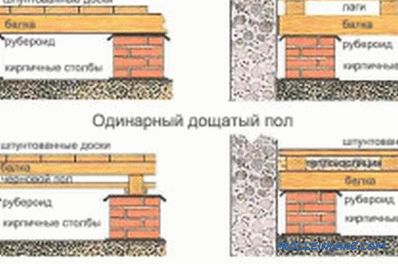

If the installation of the floor is supposed to be done on the ground, it is necessary to make the bases for the columns, which will be built of brick. They need to install lags, but before that between them and the supports should be laid roofing material, which will act as a waterproofing agent. After the spaces formed by the lags are filled with a heat insulator, the height of the underfloor space should be approximately 20 cm. The distance between the lags will be selected depending on their thickness, the pitch can vary between 90-120 cm.

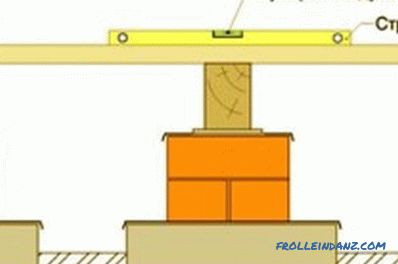

In a wooden house, an overlap of reinforced concrete can also be equipped, which requires a different preparation; it presupposes the arrangement of bedding made in the form of a mixture of slag and sand. Only after this you can install the lag, the distance between which should be equal to 60 cm. It is necessary to fix the logs with the help of anchor bolts, while it is important to maintain horizontal installation of the material, applying a level.

As a rule, logs that creep in a wooden house are made of bars with a rectangular cross-section, which allows you to mount the floors on their surface. But at the step between the beams, which exceeds 80 cm, it will be necessary to make an additional installation of an even rough coating.

Features of laying lag

Laying pattern of lag.

Lags should be laid across the light. If it is intended to install them in the corridor, then the elements of the system should be located perpendicular to the entrance.

Lagging in a wooden house on the ground is made with pre-leveling and tamping of the soil. The procedure can be carried out manually, for this purpose it will be convenient to use a large log, to the bottom of which a board should be nailed, such a design should be moved along the surface of the dirt floors together. The thickness of the board must be 50 mm.

Now you can proceed to the measurement and marking for the supports, which will be lagged. When used as supports for the lower trim bars, it is permissible to make markings directly on them using a pencil. If the support is a grillage protected by roofing felt, marking can be done on the roofing felt.

When installing it should be remembered that the distance from the lag to the walls should be equal to the limit of 3-20 cm. In order to equip the supports for logs, you need to install the foundation for them. In this case, for each pillar, you can equip your base, and you can make one foundation for a number of pillars. As the smallest dimensions of the base for a single support, you can use 40x40 cm, with a minimum height of 20 cm, 5 cm of which should be made above the soil surface. In order to equip the base under the pillars, from the mark made for the beams for the lag it is necessary to postpone in both directions by 20 cm, between the marks obtained to pull the cord.

Set the lag and check the horizontal position before laying the floor.

The same procedure must be performed in a plane located perpendicular to the logs, this will allow you to designate the angles of the supports, which will be located at the intersection of cords. Now you can mount the pegs in the corners, then you can get rid of the laces. If you decide to arrange the base for the supports, only the edges of the row should be marked with laces. In the designated areas should get rid of the soil. Next, you need to fill the rubble, and then ram it. In the part of the foundation that was serving, it is necessary to make a formwork, its height must be equal to 10 cm.

To waterproof the concrete base, a film must be laid in the pit.If the soil is clay or a clay lock was executed before, waterproofing should be discarded. Now you can proceed to the reinforcement using the mesh, made of steel reinforcement, the diameter of which is equal to 8 mm. It should be mounted slightly below 1/2 of the future cement layer. After that, you can proceed to fill the space with concrete. To do this, you can use "lean concrete", it should be a larger amount of aggregate, which act as sand and gravel, and the binding element - cement, should be less.

After 3 days you can proceed to waterproofing, the material should be laid, missed bitumen. Now you can proceed to the arrangement of the support pillars, on which the lag will be laid. When using bricks for this, the laying process may consist in the formation of 2 layers, the last of which should be located perpendicular to the position of the lag in length. Installation of products (brand of at least M 100), which will act as supports lag in a wooden house, must be made on a solution of cement and sand. The installation process at the next stage involves laying waterproofing, for this you need to use roofing felt, which will be cut into squares, their side should be equal to 25 cm, the resulting material will be laid on top of the support. Next must be laid sound insulation strip.

The first lags will be the so-called lighthouse lags, which are mounted on the edge of the walls in 2 m steps.

Technology laying wooden floors and wood processing.

When mounting, their horizontal position will have to be adjusted by level. From their position will depend on the evenness of the installation of the remaining lag. It is important to check the correctness of their installation not only in relation to each other, but also in relation to the floor. If the process of their installation did not give positive results, the irregularities should be removed using a planer; in the case of deflections, liners should be laid under them. The largest deviation that can be is 1 mm per 1 m.

Now you can do lags, which will be located in the intervals. Their fixation to the posts in a wooden house should be done with the help of corners and screws, the latter should enter the timber by 5 cm. The second part of the corner should be fixed to the support with the help of dowels.

Installation of wooden floor

Technology of installing wooden floor on plywood.

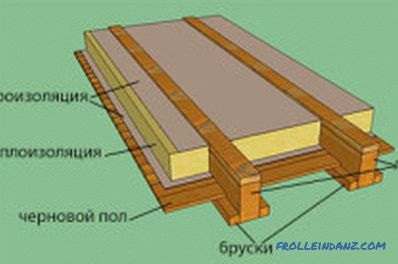

Before you install the floor, you should finish all work on the walls, this will eliminate the contamination of the topcoat. In order for the wooden house to be even warmer, it is necessary to make heat insulation before laying the clean floor, for this insulation should be installed in the space between the lags. When insulating floors in a wooden house, you can use basalt fiber, polystyrene foam or other material.

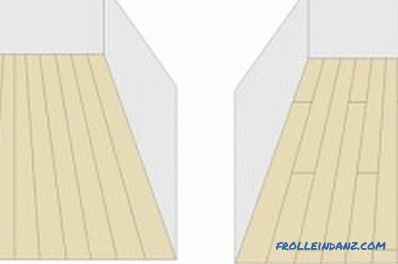

Laying the floor in a wooden house should be started from the corner farthest from the door. The starting row should be laid with a groove 10 mm from the wall. Elements of the floor can be strengthened with screws to the logs. In order to eliminate the splitting of the board, the holes must be drilled in advance.

If the dimensions of floorboards are smaller than the length of the room, all subsequent rows should be laid with a certain offset. The annual rings that are on the floorboards should be alternated. In one row they must be placed with the direction in one direction, in the other - in the opposite direction.

When installing the floor in a wooden house in the last row of the board, it is necessary to strengthen the screws so that the baseboards are able to hide the caps.

A wooden house will become more harmonious after the arrangement of wooden floors, since it is not only more aesthetically pleasing, but also more comfortable than other options for finishing coatings. Arrangement of such a floor is easy to produce, and materials are very inexpensive and durable with proper pretreatment.

Laying the parquet on the logs

The wooden floor on the beams.

A wooden house will look great with an alternative to the natural floor, made of wood - parquet. If the parquet is laid on the logs, you can do without leveling the surface.

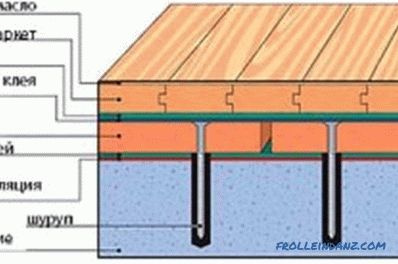

In this case, logs should be laid on the base of the rough floors in the wooden house, the distance between which should be equal to the limit of 40-80 cm, the installation of the bars should be done along and across. After aligning their positions, wooden elements can be drilled to the surface with dowels. As a result, the floor surface will resemble "honeycomb". Such laying of the floor also allows for additional insulation. In the honeycomb floor for this should be laid insulation, in the role of which can act as expanded clay. If the wooden house requires sound insulation, you can put foam, but another sound-absorbing material will do. It is permissible to use materials for different purposes together.

Now you can proceed to the installation of moisture-resistant plywood, its thickness should be equal to 18 mm. Installation needs to be made on logs, drilling the material with screws. A wooden house will have a floor with better waterproofing, if you install the glassine between lags and plywood, it will perfectly cope with the task of implementing a special roofing material during the installation of this technology.

In country houses, when arranging the floor on the logs, the bars must be treated with a special compound that prolongs the life of the material. Now parquet can be laid on the surface of plywood.

If you still have not decided what is best to install - logs or cement screed as a subfloor, it is worth noting that these options are about the same cost.

Alternative flooring options for a wooden house

Types of construction of floating plank floors.

In addition to the above flooring options for a wooden house, you can prefer ceramics, linoleum, laminate or cork. If you decide to choose a ceramic tile so that its appearance is in harmony with the naturalness of a country house, it can be made as wood imitation. But in order for it not only to look aesthetically pleasing, but also to be comfortable for perception, a warm water floor can be laid under its base. Then you should initially get rid of the subfloor, level the base, fill the surface with gravel, then tamp the pillow, reinforce the space, lay the pipes along which the water will move, and then you can start pouring concrete. Ceramics will fall perfectly on its surface after drying.

But if you decide to use a cork as a topcoat, it is preferable to use its adhesive performance. Its installation can also be made on logs protected by plywood. However, it is necessary to get rid of the seams at the base with the help of putty designed for woodworking. And the beginning of laying cork should precede the priming of the base.

It is important and correct to choose an adhesive composition for the cork, it is better to use latex-acrylic compositions, they will perfectly hold the material on concrete bases.

Glue should be applied with a roller on both surfaces, pressing the cork tile to the base. As soon as the glue dries, you can tap the surface of the coating with a rubber hammer.

Whatever floor you decide to mount, you should follow all installation rules, it is especially important to check the horizontal position and the reliability of the installation of the elements, then the floor will not only please the eye, but will last for a long time.