Time does not stand still, therefore new technologies are replaced by new ones - light, practical and environmentally friendly. The wooden beam was always popular, but only in the XXI century they began to manufacture an I-beam made of wood, which made it possible to significantly refine the frame construction.

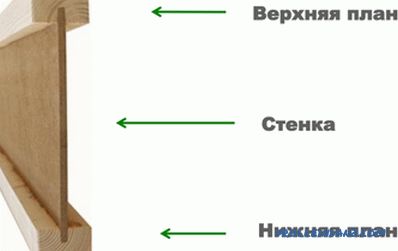

Scheme of an I-beam.

Basic parameters of the product

With each new season this material increases its popularity. It is usually used for frame construction, installation of floors, ceilings and partitions, as well as roofing. The specific type of the Latin letter "I" with bars at the top and bottom allows for installation rather simply and quickly.

There are several advantages due to which the I-beam became popular: not bend, wear resistance, lack of response to moisture (does not rot), low weight and at the same time relatively low price due to reduced wood consumption.

If we look at the product in detail, we can see that it is not integral, but consists of several elements. The basis of the OSB (oriented strand board) or plywood, the blocks below and above are made of laminated veneer lumber, and all this is connected with water-based glue on wood. In the glued laminated timber there are special grooves of the required width, which allow you to immerse the PCB in them, thanks to which the design also acquires its highest reliability.

Drawing of the I-beam.

In the factory, 4 machines are used for this process:

- Milling. On such a machine, in a timber not only a longitudinal trench is made, but also polishing is carried out, so as not to injure the skin during operation.

- Cutting OSB. It works parallel to milling in order to cut the required number of plates with perfectly accurate parameters by the time. Cuts are made at an angle of 45 °.

- Gluing. A thin layer of glue is applied to the bottom of the trench, after which a plate is inserted between the 2 bars, and the entire structure is pressed down.

- Press. Depending on the glue used, the machine holds the billet (0.5–2 min.) Under pressure, and then rolls on to the final drying.

Work takes place at a very high speed, but not all of these products are solved, because with manual production the price is 1.5-3 times lower.

Handwritten study

Tools and materials:

- cant;

- tape measure;

- circular saw;

- OSB;

- glue on wood;

- channel;

- clamps;

- emery cloth.

Here the whole process is much slower, but the price drops significantly. I-beam is made in stages:

I-beams are made from timber, OSB and channel bars.

- The bars are selected. The section depends on the preferences of the master, but not less than 35 * 25 mm. The larger the bar, the more reliable the design, but the step of 2 I-beams when working will have to be significantly increased.

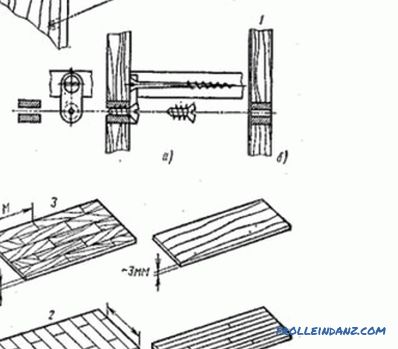

- Here you should choose what to use - a power saw, a chainsaw or a stationary circular saw. The advantage of chainsaws is that they can initially make a trench of 10-12 mm, but they need to be further secured. In addition, their work is much more expensive than the circular. With a special desire, you can find cutters of the desired thickness for a circular saw (cost a little more than usual), after which you can continue to work.

- The furrow depth is set (10% of the total OSB length). With a total loss of 1/5 length, you can achieve perfect fixation.

- The bars are cut. At the same stage, they need to be sanded using a sander or sandpaper.

- Glue is applied to the bottom of the trench, after which the slab is immersed in it. Immediately, a similar process is done with another 1 bar, and an I-beam can be pressed.

- Not every home has a hydraulic press, so you can use the channel, which is tightened with the help of 2 belts and carbines (improvised clamps). Such an I-joint screed is no less effective than a press, albeit more troublesome.

In total, it takes up to 30 minutes to make 1 I-beam. but if done on a stream, then the speed will increase several times. That is, first, for example, 100 beams are cut, which are polished, then 50 slabs are cut, after which all of this is subject to gluing. With such work, the average production rate of 1 I-beam can fall to 8-10 minutes. but in no case should not rush to avoid a mistake.

Anyone can do this kind of work if there is a special technique and basic skills of working with it.

It is very important not to forget about TB, so that later savings on building materials will not turn into hospital expenses.

Didn't find the answer in the article? More information on the topic:

-

How to make floors in a wooden house

You can make wooden floors as well as other materials for this. If bricks were used to organize the foundation, the beams are placed immediately behind the basement floor.

-

Making wooden arbors with your own hands

Construction of wooden arbors with their own hands on the garden. Features of the construction of the foundation. Construction harness. The frame and flooring, especially the roof of the wooden arbor.

-

We make hinged shelves with your own hands

Mounted shelves with their own hands are made of various materials. For fixing the shelves to the wall, the usual corners, hinged brackets and invisible fasteners are used.