Are you a country owner? If yes, then you know that in the country to do without a hoe-block (or a shed) is simply impossible. In it, you can store supplies, various tools, agricultural tools and garden items. This is a necessary building, and if you do not have it, you can think about its construction. Moreover, you can build a hozblok to give their own hands, since special work and special skills are not required. We suggest you study the material that will help you to make a barn from start to finish.

Stage 1: Designing

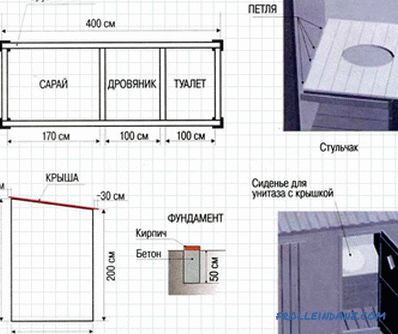

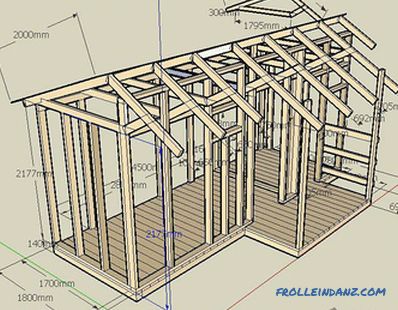

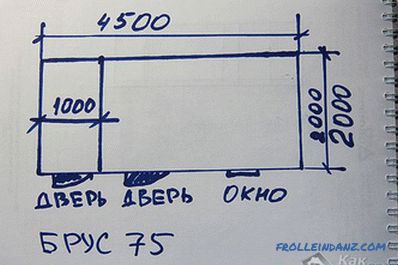

The control block drawing

The control block drawing

The building block can help you solve several problems:

- the room will serve you as a workshop and storage for tools and equipment;

- the building may have additional zones, such as a shower and toilet;

- it can be equipped not only with a bathroom, but also a place for recreation - a room with upholstered furniture and amenities.

All of this can be achieved through planning. A shed can be one of the 3 types of buildings listed above, and can include all of them. It all depends on your needs and desires.

You should not assume that the shed should be inconspicuous and ugly. You do not need to set a task to do it with minimal expenses. Thanks to the efforts and work, you can make a wonderful hozblok that will not be inferior in beauty and functionality to your country house.

When making drawings, think about the size, height and number of compartments you need. Moreover, when designing a building, remember that it must meet the following criteria:

- The most correctly allocated space.

- Long operational life and reliability.

- Carrying out the necessary communications: electricity and water. If your utility room with a toilet, you need to provide sewer drain.

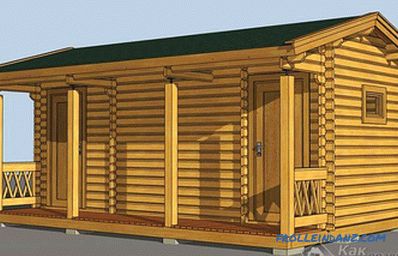

Hozbloki from a bar

Hozbloki from a bar

You will not spend a lot of money on the construction of such a barge, therefore When choosing a material, stop on a wooden bar. This is the most common and suitable material. For example, buildings from a usual board will not stay long. But hozblok on the foundation with a frame of timber meets all the requirements and will serve you for many years.

If you can not make a project of your dog house, use the world wide web. Especially for those who do not know how to do projects, people put ready-made drawings. They can be downloaded for free or bought for a symbolic amount.

To create a hoe-block, prepare such tools and materials:

- ax, shovel, screwdriver, handsaw, electric drill with a set of drills, plane;

- bars, cladding boards, metal anchors;

- finishing materials for roofing and walls, cladding panels, heat insulation (if needed).

Stage 2: harvesting material

Lumber

Lumber

purchased to make a hozblok, the dimensions of which are 6 m long, 3 m wide and 3 m high, with a lean-to roof and two interiors, you need to prepare such materials:

- plywood - 28 m 2 ;

- ruberoid - 28 m 2 ;

- timber 150 * 150 mm - 0.65 m 3 ;

- timber 150 * 100 mm - 0.37 m 3 ;

- bar 100 * 100 mm - 1.2 m 3 ;

- bar 50 * 100 mm - 0.15 m 3 ;

- edged board 30 mm - 2.2 m 3 ;

- batten 40 mm - 0 , 37 m 3 ;

- asbestos-cement pipe Ø 150 mm - 6 pcs. 1200 mm;

- gravel, sand, cement;

- fittings - Ø 10 mm, 350 mm long, 4 pcs.

This is the end of the preparatory work. The next step will be the correct location of your cabins.

Stage 3: selection of a place

Planning of the suburban area

Planning of the suburban area

It is clear that to build a utility block on your own, you do not need special cash deposits. But be prepared for the fact that the construction process will take away your time and effort. To make work faster, ask for help from households or neighbors. However, just prior to construction, you need to choose where to place the barn so that it is comfortable and meets the requirements. Building norms and rules (SNiP) at 30. 02. 97 paragraph states that:

- in the case when there are pets, birds in the household unit or it will serve as a lavatory, it should be placed on 12 m from the walls of a residential building and 4 m to the border of the neighborhood;

- if it will be used as a shower, it should be placed 8 m from the residential building and 1 m from the border of the neighborhood.

If you neglect such requirements, you may have serious problems when you want to sell your plot. In this case, the state will refuse to execute a sale transaction with buildings until their placement complies with the standards in force in the territory of the Russian Federation.

Having chosen the optimal place, we smoothly proceeded to the main question of how to build a building block at the dacha. Let's find out.

Stage 4: laying the foundation

Pillar foundations from within

Pillar foundations from within

So our the goal is to build a building of 6 * 3 * 3 m. Since the building itself will not produce a special load on the foundation, it can be made columnar. To make it easier for you, we will divide all the work into separate stages.

- At the place where the shed will stand, you need to remove the top layer of fertile soil around the perimeter of the building, having pre-marked the future site based on the project.

- The prepared place must be tamped down, covered with 10 cm of sand from the top and properly tamped again.

- Six pillars are needed for such a construction. Drill or dig a hole of Ø 20 cm, depth 120 cm in the intended place. Please note that the columns to be installed also have a length of 120 cm.

- A layer of sand 10 cm or gravel should be filled to the bottom of the holes and then tamp this pillow.

- Lower the holes in the asbestos-cement pipes into the holes. Level them vertically. To fix the pipes, the remaining space between the hole and the walls must be filled with sand and compacted.

- The time has come for the first stage of the filling of the pillars. Prepare the concrete and fill it with 1/3 of the entire length of the asbestos cement pipe. Then the pipe must be raised to 10-15 cm, set the level, fix and wait 2-3 days. Such manipulations allowed the formation of a base of concrete at the bottom of the pits. The diameter of the base will be larger than the diameter of the pipe, which will not allow the columnar foundation to rise when the ground wakes up in winter.

- After the concrete has dried, you can pour the remaining cavity of the pipes. But before that, prepare 4 bars of Ø 10 mm reinforcement, thanks to which the grillage of the beam will be securely fixed to the posts. They will need to be drowned in 4 corner pillars. From the total length of trimming the armature - 15 cm is necessary for immersion into the pipe, and 20 cm will protrude.

- If you consider reinforcement fixation to be unreliable, an anchor can be fixed in such a foundation. They are placed on the frame and secured with nuts. In this case, the end of the anchor and the nut should be drowned in the grillage.

- With the solution prepared, fill each tube with it. As casting, compact the concrete with a bayonet to force air out of it. Then install the fixture reinforcement exactly in the center.

- It remains to wait for the solution to solidify, which will occur after 2-3 weeks. During this time, you need to cover the pillars from the sun and wet them with water in dry weather.

This completes the foundation installation work.

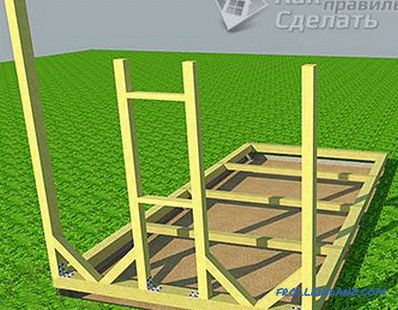

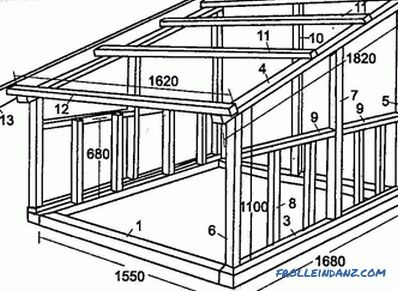

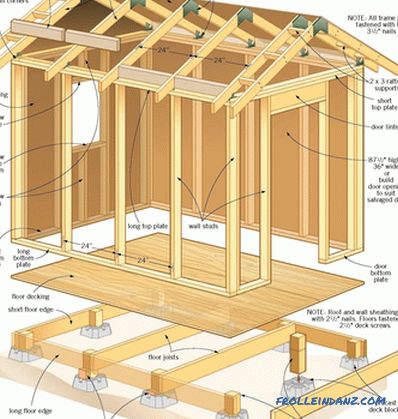

Stage 5: assembly and installation of the grillage (frame)

Assembly and installation of the grillage

Assembly and installation of the grillage

The frame must be assembled from bars, the cross section of which is 150 * 150 mm, its size will be 6 * 3 m. The frame will consist of four sections, 1.5 * 3 m in size. The bars, which form the frame, are interconnected by grooves " in the wood. " They need to be fixed with special two (if the frame is installed on the anchor) or four (if installed on the reinforcement) wood screws. To install the frame on the foundation, in the right place should be made holes for the protruding reinforcement or anchor.

In order to ensure sealing, one should put 1-2 layers of roofing material on the poles so that its edges protrude 10 cm. They need to be bent down so that the water runs off and does not accumulate under the wooden bar. Before you put the frame on the foundation, the wood should be covered with an antiseptic - put at least 2 layers of drying oil. Then the frame is installed and attached to the foundation. The length of the frame you need to install three lags "half-timbered" from a bar 100 * 100 mm, in increments of 135 cm.

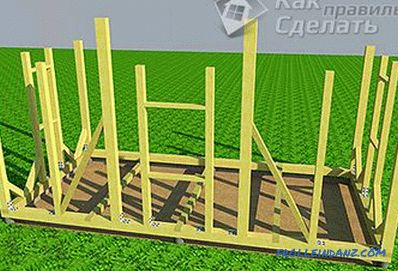

Step 6: the frame of the economic unit

Manufacturing frame

Manufacturing frame

To build the frame, wooden bars with a cross section of 100 * 100 mm and 100 * 150 mm are required. For the convenience of further roofing, mount frame timber need different heights. The front side of the frame will be 3 m high and the back side 2.4 m. Thus, it will be easy for you to install the rafters for a single-sided roof.

Assembling the end frame The first step is to assemble the same end walls. In each of them will be an opening for the window. To the frame of the rack are fastened vertically with galvanized steel corners, 130 * 10 mm or 105 * 90 mm in size and self-tapping screws. First you need to put the corner stand, whose height is 3 m, and the cross-section of 150 * 100 mm, narrow side to the end. To do this, it is necessary to make a hole of Ø10 mm and a depth of 50 mm in the bottom in order to fit the timber on the reinforcement that protrudes from the frame. The same holes must be made in the other three corner bars. Departing 1 m from the corner, you need to fix the other two bars, the cross section of which is 100 * 100 mm and the length is 2.4 m. The distance between them should be 0.6 m.The last on the end wall will be a corner bar that sits on the armature. Its height is 2.4 m, and the cross section is 150 * 100 mm. All racks are fastened corners. And in order for the design to be strong and rigid, between 1 and 2, 3 and 4 racks it is necessary to make struts with a cross section of 100 * 100 mm. To do this, the ends of the struts need to be cut at an angle of 45 ° and attach them to the frame and racks with the help of bolting. Be sure to put a washer before tightening the nut. Between the 2 and 3 racks you need to insert window beams, the cross section of which is 100 * 50 mm. The first bolt is installed at a height of 1 m from the frame, the second - at 1 m from the first. The second end frame must be assembled in the same way. As a result, you should have, as in the figure.

Assembling the end frame The first step is to assemble the same end walls. In each of them will be an opening for the window. To the frame of the rack are fastened vertically with galvanized steel corners, 130 * 10 mm or 105 * 90 mm in size and self-tapping screws. First you need to put the corner stand, whose height is 3 m, and the cross-section of 150 * 100 mm, narrow side to the end. To do this, it is necessary to make a hole of Ø10 mm and a depth of 50 mm in the bottom in order to fit the timber on the reinforcement that protrudes from the frame. The same holes must be made in the other three corner bars. Departing 1 m from the corner, you need to fix the other two bars, the cross section of which is 100 * 100 mm and the length is 2.4 m. The distance between them should be 0.6 m.The last on the end wall will be a corner bar that sits on the armature. Its height is 2.4 m, and the cross section is 150 * 100 mm. All racks are fastened corners. And in order for the design to be strong and rigid, between 1 and 2, 3 and 4 racks it is necessary to make struts with a cross section of 100 * 100 mm. To do this, the ends of the struts need to be cut at an angle of 45 ° and attach them to the frame and racks with the help of bolting. Be sure to put a washer before tightening the nut. Between the 2 and 3 racks you need to insert window beams, the cross section of which is 100 * 50 mm. The first bolt is installed at a height of 1 m from the frame, the second - at 1 m from the first. The second end frame must be assembled in the same way. As a result, you should have, as in the figure.

Assembling the front of the frame Now you can assemble the front frame. Level the main pillars with a height of 3 m. There should be four of them, two of which are already standing in the corners. It remains to establish two medium racks. From the extreme posts you need to retreat 1.8 m and fix them. So that they do not stagger, for a while connect them with a board on nails or screws with each other. Since the hozblok will be divided into two separate sections, you need to make the window opening in the middle and the doorways on the sides. The door frame will be 2 m high and 0.85 m wide. Therefore, take a stand 2.4 meters high with a section of 100 * 100 mm and set it at a distance of 0.85 m from the stand. Do the same on the other side. In order to strengthen the structure, set diagonal braces between the 2nd and 3rd pillars. On the other hand, do the same. Next, you need to install window racks. Again, take a timber 2.4 m high with a cross section of 100 * 100 mm and secure it at a distance of 0.37 m from the third pillar (which is 3 m high). Then retreat 0.85 m from the installed rack and set the second one, exactly the same. It remains only to insert the horizontal bolts. Fix the first one at a height of 0.8 m from the frame, the second - 1 m from the first. Now the front side is ready, you should go out as shown.

Assembling the front of the frame Now you can assemble the front frame. Level the main pillars with a height of 3 m. There should be four of them, two of which are already standing in the corners. It remains to establish two medium racks. From the extreme posts you need to retreat 1.8 m and fix them. So that they do not stagger, for a while connect them with a board on nails or screws with each other. Since the hozblok will be divided into two separate sections, you need to make the window opening in the middle and the doorways on the sides. The door frame will be 2 m high and 0.85 m wide. Therefore, take a stand 2.4 meters high with a section of 100 * 100 mm and set it at a distance of 0.85 m from the stand. Do the same on the other side. In order to strengthen the structure, set diagonal braces between the 2nd and 3rd pillars. On the other hand, do the same. Next, you need to install window racks. Again, take a timber 2.4 m high with a cross section of 100 * 100 mm and secure it at a distance of 0.37 m from the third pillar (which is 3 m high). Then retreat 0.85 m from the installed rack and set the second one, exactly the same. It remains only to insert the horizontal bolts. Fix the first one at a height of 0.8 m from the frame, the second - 1 m from the first. Now the front side is ready, you should go out as shown.

Top trim Now make the rear facade. Since the corner posts with a height of 2.4 m are already standing, it remains to put 2 intermediate, with the same height and section of 150 * 100 mm. Step from the end of the stand - 1.8 m. After that, install two braces between 1 and 2 of the rack and 3 and 4.

Top trim Now make the rear facade. Since the corner posts with a height of 2.4 m are already standing, it remains to put 2 intermediate, with the same height and section of 150 * 100 mm. Step from the end of the stand - 1.8 m. After that, install two braces between 1 and 2 of the rack and 3 and 4.

It remains to make the top trim, for which you need a 100 * 50 mm bar. Mount it at a height of 2 m from the grillage (frame). To do this, pieces of timber need to be fixed vertically between all racks around the perimeter. It is necessary to connect them end-to-end, fixing with a reinforced steel angle and screws. As a result, you should have such a wooden frame, as in the figure on the right.

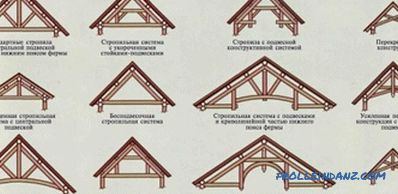

Stage 7: fixing rafters

Fixing rafters and lathing

Fixing rafters and lathing

Assemble rafters more convenient and easier on the ground. It turns out, you will mount them on the rack frame in the finished form. In order for the roof to have a visor that will protrude around the perimeter, take rafters 5 m long with a section of 100 * 50 mm. Connecting them to each other will be crate of 30 mm edged boards. Rafters are placed in increments of 0.85 m. The crate does not necessarily attach tightly to each other. It all depends on the roofing material. If its mass is small, the distance may be greater, but if it is large, the boards fit more closely.

To install the roof, in the racks on which it will be supported, it is necessary to cut the slots at an angle of 10 °. Why 10 °? Because the height difference between the front and rear pillars creates exactly this angle. Before you install the roof, you will have to sew up its overhangs and eaves with a edged 30 mm board. After this, make the floor using a floorboard. It is possible to use both nails and screws. In the racks make holes for screws. To raise the finished roof up, you can use logs, which must be placed behind the building. On them the design is lifted up, the rafters are installed in the grooves on the racks and everything is fixed with self-tapping screws.

Stage 8: trim and interior work

Interior finish

Interior finish

Now, when the frame is completely ready, it remains to perform the outer casing. Lining is suitable for this purpose. Then you need to lay the roof covering that you choose, insert the windows and install the doors. To separate the two sections inside the hozblok, make a frame-shield partition, using a half-tree connection. Fiberboard or plywood sheathed ceiling of the building (you need to fix the materials with screws). Optionally, you can sheathe base, using asbestos cement sheet. And if this is done from the inside and outside, filling the space with expanded clay, then it can be insulated with mineral wool or foam. Then the building will be much warmer, which will allow using it not only as a warehouse.

If you like this project, write to us in the comments.You can also share other options that can be realized on your own!

Video

Watch a video on how to build a barn to give yourself:

This video shows the construction of a wooden hozblok:

Photo

Manufacturing of the hopper

Manufacturing of the hopper

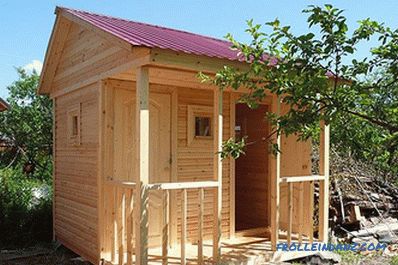

Shed at the cottage

Shed at the cottage

Hozblok with toilet for giving

Hozblok with toilet for giving

There is a compartment for firewood

There is a compartment for firewood

Hozblok with room

Hozblok with room

Hozblok at the dacha

Hozblok at the dacha

The structure of foam blocks

The structure of foam blocks

Hozbl k for giving

Hozbl k for giving

The wooden hozblok opened with wood stain

The wooden hozblok opened with wood stain

Wooden hozblok

Wooden hozblok

What can be in hozbloke

What can be in hozbloke

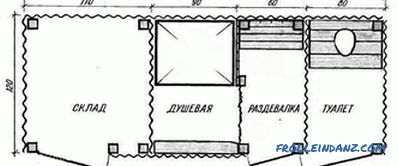

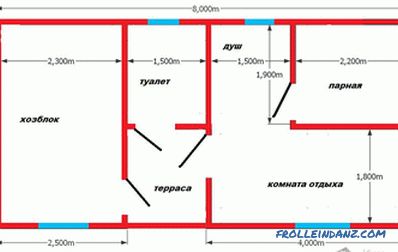

Drawings

Design drawing with shower and toilet

Design drawing with shower and toilet

Bath project with hozblokom

Bath project with hozblokom

Drawing 5 * 2. 8

Drawing 5 * 2. 8

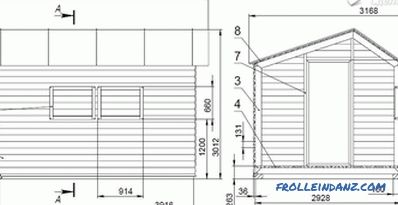

Drawing of the shed 3916 * 2928

Drawing of the shed 3916 * 2928

Drawing of a single-shed roof hopper

Drawing of a single-shed roof hopper

Drawing of the hopper framework

Drawing of the hopper framework

Construction from a bar

Construction from a bar