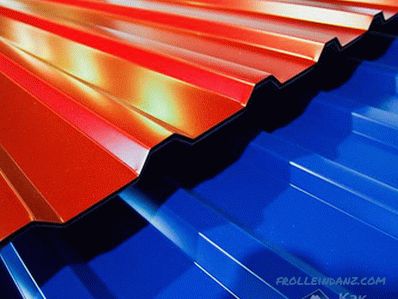

Profiled sheeting is a universal material made on the basis of galvanized metal sheet, widely used in modern construction practice. Elegant and attractive forms of roofing, made of profiled sheets of bright colors, are quite often found today in houses of private buildings. Often they are made in the form of a combination of geometric shapes of various configurations, giving the roofing surfaces a special chic and originality.

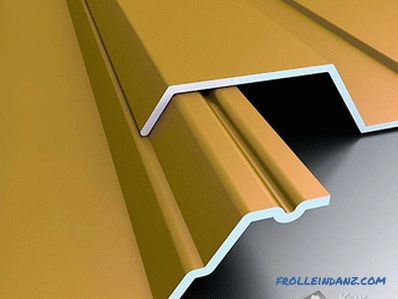

Roof decking with a capillary groove

Roof decking with a capillary groove

Before you cover the roof with a professional flooring, we advise you to familiarize yourself with the advantages of this material, and also take into account some features of working with him.

Advantages of using a professional flooring

The main advantage of a professional flooring is the possibility of its independent installation, produced without the involvement of third-party workers. In this case, you can get by with just a few people invited as assistants.

First of all, you should know that the profiled billet is made of cold rolled metal sheet having a combined protective coating. The sheet billet formed in this way has the following advantages:

- the profiled sheet has a sufficient thickness to ensure the resistance of the roof covering to mechanical loads (to the effects of wind and compacted snow);

- a multilayer coating that includes It has a special paint layer that reliably protects the metal base from the destructive action of moisture (from corrosion);

- galvanized corrugated flooring is cheaper, but over time this coating dims;

- the cost of Container material can please a potential consumer of their availability.

Installation Features

Anyone wishing to become familiar with how to properly prepare the roofing of corrugated board, first of all, you must take into account some of the features held with operations. These features in the first place should include:

- method of delivering sheet material to the place of work (in the attic of the building or repaired structure), ensuring complete preservation of the appearance of the material;

- manufacturing procedure

- safety of operations performed, ensured by the observance of the rules for working with metal (using work clothes and gloves, for example), as well as the need to use soft shoes to move of flooring material.

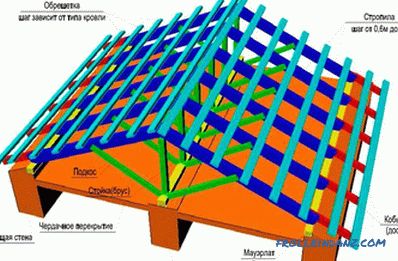

Lath

Lath

In addition, before starting work, it is necessary to determine in advance the basic characteristics of the mounted truss system (step rafters, the angle of the overhang of the roof, etc.), which, in turn, depend on the configuration of the coating itself.

In the most general case (when installing roofs of complex configuration) it is necessary to ensure that the following conditions are met:

- First of all, fixing elements of the lower end are to be prepared (adjoining adjacent planes of the roof, which serves to drain rainfall).

- The laying of the roof covering itself should begin with the fastening of the end eaves, located approximately at the level of the waterproofing layer.

- Installation of the coating begins, as a rule, from the angle of the roof (in cases with hip constructions from the center of the hip);

- The amount of overlap between adjacent sheets (the so-called overlap) is chosen depending on the angle of inclination roofing It usually has a value from 150 to 200 mm, but not less than the width of a single wave.

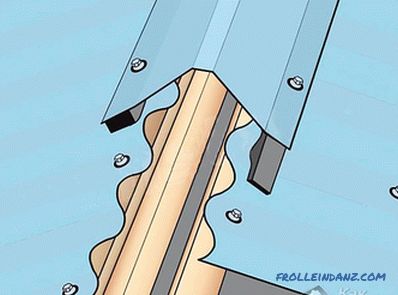

- At least seven self-tapping screws should be used to secure each sheet; moreover, the most important joints are sometimes reinforced with special steel rivets.

Before final fixation of blanks arranged in a row, all of them are subject to mandatory alignment along the lower section of the ramp.

Installation in the area of the valley, ridge and pipes

Installation in the area of the ridge

Installation in the area of the ridge

When installing a professional flooring, you are sure to encounter the need to finish such places that are inconvenient for laying, such as valleys, chimney pipes, skate and other adjacencies. For their finishing it is necessary to use special elements that are included in the set of covering from the profiled sheet.

The installation procedure for the adjoining elements is as follows:

- To arrange the gutter at the dormer window, you will need a sheet cut into two parts, which should be prepared in advance. When finishing the window, the lower half is first cut into the blank, then the so-called bottom plank, and only the roofing sheet itself is mounted above it.

- The installation of a special end plate of two meters length with an overlap of about 50-100 mm should be started from the overhang side with a gradual shift towards the ridge. The bar is mounted on a previously prepared end plate with a pitch of about 1 meter. The unused residue of the plank is simply trimmed.

- When working with roofing materials, it is recommended to use special seals with a small corrugation, placed directly under the sheet to be mounted. The amount of overlap between adjacent sheets (overlap) should be about 100 mm.

- In the area where the chimney is placed on the roof, the laid sheet is pre-cut according to the shape of the pipe, after which the joining points are closed with special elements (connecting bars) that form a kind of "apron" around the pipe.

- When finishing the ridge of the roof, special ridge elements are used.

Fastening and sealing elements

Roofing screws

Roofing screws

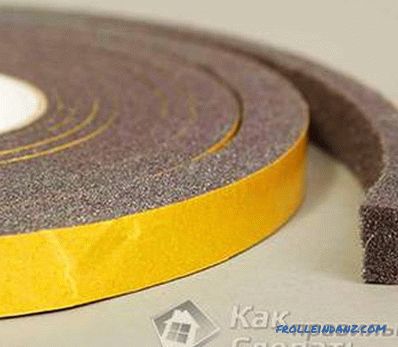

Roofing compactor self-expanding To fix the blanks from the profiled sheet, it is recommended to use special galvanized self-tapping screws, complete with sealing gaskets made of elastic material. The caps of fasteners should be protected by a special composition, matched to the color of the coating and providing them with the necessary resistance to corrosive, mechanical and ultraviolet effects.

Roofing compactor self-expanding To fix the blanks from the profiled sheet, it is recommended to use special galvanized self-tapping screws, complete with sealing gaskets made of elastic material. The caps of fasteners should be protected by a special composition, matched to the color of the coating and providing them with the necessary resistance to corrosive, mechanical and ultraviolet effects.

Often, in practice, special gaskets are used in the installation of corrugated sheeting to ensure a tight fit of the coating material to the base strips. The use of sealing elements helps to protect the roofing elements of the structure from climatic precipitation in the form of rain, snow, wet drizzle, etc.

Such protection not only increases the service life of the truss system, but also contributes to improving the sound insulation characteristics of the entire coating as a whole.

Seals on roof skates

Seals on roof skates

Currently, building materials manufacturers produce sealing elements that repeat structure of corrugated surface of corrugated sheets. In addition, there are commercially available special seals to ensure reliable fit of the ridge roof elements.

We also recommend that you familiarize yourself with the materials:

- solar battery with your own hands from improvised means;

Video on working with roofing material of the class we are considering at the end of the article.

Video

Video about installing professional flooring with your own hands. In the process of viewing the author will share some professional secrets about which very few people tell:

Photos