Plywood is a universal material. It is very widely used in construction, it is lightweight, durable, environmentally friendly and has a democratic price. Plywood is often used to create flooring or repair floors. To figure out how to make the floor of plywood correctly, is not particularly difficult. Since this material is universal, it can be used in various cases, but the application technique will vary depending on certain conditions.

The floor of plywood is durable and easy to install, which is why it is very popular in interior decoration.

Types of material

Many types of plywood are produced today. In construction, such grades are used more often:

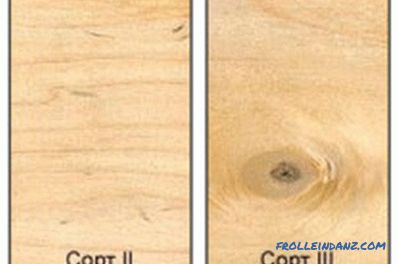

Plywood grades.

- FC - moisture-resistant plywood, based on non-toxic, non-volatile carbamide resin, very elastic and durable.

- NSH - plywood unpolished on casein glue. It is considered the cheapest, with a thickness of 12 mm. If you plan to glue parquet or similar hard material on such plywood, you must first sand it with sandpaper.

- Ш1 - material for the construction of a subfloor. Plywood is ground on one side, casein glue base.

- Ш2 - also on a casein basis, grinding on both sides. If the room where it is necessary to arrange the floors is dry enough, with a normal temperature, and no extensive loads are assumed, you can use it as a substitute for plywood FK.

In wet rooms it is undesirable to use plywood - this building material is hygroscopic and deteriorates quickly in wet conditions. Plywood intended for floors and walls should not be used on balconies and kitchens, in toilets and bathrooms.

How to prepare plywood before work

Existing plywood dimensions.

To improve the moisture resistance of plywood, it is impregnated at home with putty on polyvinyl acetate - it resembles liquid PVA glue and is very inexpensive. The treatment starts from one side and soaks the plywood as abundantly as possible. Then impregnate the other side, imposing impregnation in two layers, the second should be applied only after the first one dries. Drying is carried out at room temperature, it will take at least 3 days. When plywood sheets dry, they must be further treated with antiseptic, which is designed to work with wood.

To make the surface layer more durable, use acrylic varnish. It should also be applied in two layers, each of which should be dried as well as possible. If, for decorative purposes, it is decided to process the plywood with wood stain, this must be done before the varnish is applied.

Before laying the plywood on the floor, it is necessary to acclimatize it. This should be done directly on the place where you intend to perform the installation. Terms of acclimatization are determined depending on the differential humidity and temperature in the room. If in the place where the material had been stored before, the conditions are similar to those in the room being repaired, a day will be enough for acclimatization. When the difference in temperatures from two to eight degrees will take two or three days, with more from seven to ten. During the acclimatization process, it is necessary to store the material in a room in a horizontal position, stacked.

How the plywood floor is performed

Plywood flooring is constructed both when constructing a new floor, and when it is necessary to quickly repair an existing one.

For different combinations of base floor and decorative topcoats, laying plywood produces a little differently.

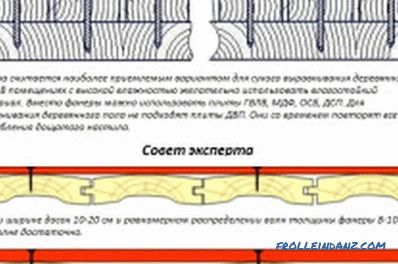

Layout of plywood on the plank floor.

When laying the material on a concrete floor, it is possible to produce it on a screed and on previously installed logs. Option number one can only be used if the base is good, even, and the material that will be used for the topcoat is plastic. The concrete screed, after the mortar has seized, must be dried at ordinary room temperature for at least 40 days.

To arrange a plywood floor with an even and dried screed, the room is carefully swept to begin with, it is advisable to use a vacuum cleaner for better cleaning. The floor is being treated, for this you will need parquet mastic or bituminous varnish, diluted in accordance with the instructions. In carrying out such work should open the windows wide, you must also wear a respirator. The apartment must be completely disconnected electricity, since the air during work will be saturated with vapors of organic solvent. Any random electrical spark here will be superfluous.

Plywood 8-18 mm thick cut into strips or squares in the size of a quarter sheet (1250Х1250 mm).It is necessary to lay them in a scramble, with a slight shift - the four seams should not converge at one point. Cutting material produced with a power tool, it can be a jigsaw or saw. When cutting, it should be noted that it will be necessary to leave a gap of 20-30 mm around the perimeter of the room.

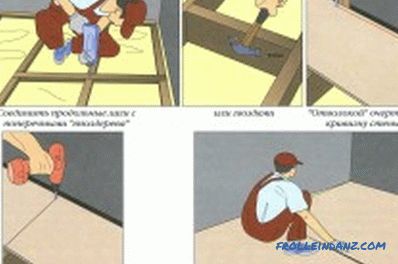

Steps for installing a plywood subfloor.

Prepared pieces of plywood are placed on the floor to make a fit, and are numbered. Under the finish coating such as linoleum or cork, you can glue the plywood to glue such as bustilat or use for this parquet mastic, without making any mounting slots. It turns out draft floating floor. The ends of the sheets, too, must be carefully glued.

Under oak parquet or similar in properties to it, it is better to attach plywood to 4X60 self-tapping screws with dowels. Distribute pieces of plywood, observing mounting slots of 2-3 mm.

Drill holes through the plywood sheet - they should be 3/4 of the diameter of the screw thread. The holes should be in the corners, in the center and in the middle of each side. Drill the central holes so that on the long side they would be displaced by about half a step, that is, by a quarter of the strip width, choose a solid carbide drill bit - the simple one gets blunt quickly, touching the concrete.

Now the plywood can be removed to the side, and in the concrete, drill holes for dowels according to the marks left from the drill. Drive dowels in them.

Apply glue to the back of the plywood with a spatula, lay the material in place. Take a screwdriver and drive the screws to the level at which the head will be slightly recessed into the plywood.

How to lay the floor of plywood on the logs

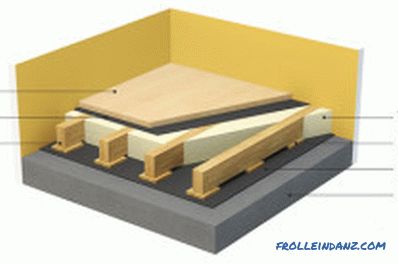

Floor alignment scheme using lag and plywood.

In some rooms, stability of temperature and humidity may be in doubt. In these cases, try to arrange plywood flooring on logs. Some points should be observed:

- For lags, you should choose unplaned boards of 100 mm.

- The material for future lags should be held at least a week in advance in the room where they are planned to be used. After that, you need to sort the boards and remove those that led or jarred.

- When choosing plywood for the floor, it is better to dwell on such a type as FC, or to self-treat the sheets with impregnations in order to improve the working properties. Its thickness must be not less than 12 mm.

- The preparation of the base is carried out in the same way as for the floor on the screed.

- From the lags, a crate is made with a pitch of 300-600 mm so that the edges of the plywood sheets would fall on the logs.

- At the lathing of the section it is necessary to fill the material with hydro- and heat-insulating properties. Polyurethane foam is well suited. Mineral wool should not be used - it causes small particles in the air, which can irritate the respiratory organs of people in the room;

- Flooring sheets of plywood should be made with an obligatory gap of 2-3 mm; 20-30 mm.

- Plywood is attached to lags using glue "liquid nails". Fixation is made with screws.

Now the finishing is done: the plywood can be covered with paints or linoleum, laminate, parquet, etc., etc.

Didn't find the answer in the article? More information on the topic: