The construction of a two-story cottage and cottage provides for the installation of an internal staircase that becomes part of the interior of the house. At the same time, it can be installed in the hall of the first floor, fitting in with the style, or hiding in the side of the house, without attracting the attention of guests. This is determined by the wishes of the future owners of the house and their needs.

Where exactly the staircase will be installed is determined by the owner of the house, but it should not be obvious.

When building a two-storey country house or cottage, a ladder (its type and dimensions) should be provided in advance in order to plan the house. In addition to the functional purpose, it carries aesthetic load in the house and is an important element of the interior.

In the process of creating a project of houses, it is necessary to calculate where the stairs should be located in the house, the size of the area under it and the height of the room. It is important to ease of use, especially if there are young children and elderly parents, for whom climbing the inconvenient and high steps can become an insurmountable obstacle and traumatic activity.

Main types of stairs

Marching stairs

The advantage of marching stairs is the ease of manufacture, as well as the possibility of lifting large-sized and heavy goods, furniture.

Marching spans have the simplest designs, and you can make them yourself. A series of steps is called a march. The advantage of such stairs is the ease of manufacture and operation, the possibility of lifting heavy and bulky goods and furniture on it. They are best suited for families with children and elderly relatives.

The disadvantage of such structures is the need to allocate sufficient space in the house to provide the required step height and slope. After ten or twelve steps in the march, they make an intermediate platform. And if the next march makes an angle with the first march, then such a design is called turning. The angle between the marches may be ninety or one hundred and eighty degrees. Swivel stairs can save space. The second marches can be two, on both sides of the first along the walls. This is determined when planning the house. Under the sloping march on the first floor is often satisfied with the storage of household items. But you can equip a cozy rest corner with a lack of free space.

Spiral Stairs

A spiral staircase can be installed in a corner or in the center of a room to emphasize it.

If there is not enough space to install the mid-flight ladder, then use a spiral design. It is also called spiral. The design of this model is more complex, its treads are made according to a special drawing to provide a circle. It can be installed in the corner or in the center of the hall in order to focus on it in the interior. Of course, this staircase is not suitable for lifting large items of furniture to the floor.

Modern architects and designers, when designing and manufacturing spiral staircases, deviate from accepted traditions and offer oval, curvilinear and broken models to customers. The spiral staircase may not have a circle in the section, but an oval or ellipse, take an S- or Z-shape. Such models attract more young people with avant-garde views. With the availability of free space, you can put an outrageous screw model in the hall, and for other family members, you can equip a simple, comfortable march design in the back of the house. The decision and the choice is yours.

For beginners who want to try to make the stairs themselves, it is better to choose simple designs. We determine the size and appearance of the staircase on the upper floor, because the layout of the second floor may depend on it. A spiral staircase requires an opening in the form of a circle. Marching stairs, depending on the size, fit into a square or rectangular opening.

Materials for the manufacture of stairs

The following tree species are used for the stairs: oak, ash, maple and coniferous.

Steps are made of stone or wood. If wood is used for the steps, the following tree species are suitable: oak, ash, maple and coniferous. An alternative to wood is shell rock, lightweight aggregate or brick. Aluminum or steel is used as a staircase fence. Wooden fencing, made of figured columns, looks good on a wide wooden mid-flight ladder. Perfectly in harmony with the combination of the above materials.

Stone steps must be manufactured in the factory to provide the required strength and guarantee safety and long-term operation.

The wooden steps are best made of glued lamellae, to avoid deformation of the wood and to provide the necessary strength and elasticity. The most suitable and affordable wood is oak.The ladder made of oak boards will provide durability and durability.

If you do not have the time and desire to do the manufacturing of the ladder yourself, to go into all the subtleties and standards, the manufacturers offer finished products from various materials, different shapes and sizes.

When ordering, you must first measure the height and width of the future product, the area allocated for it, the angle of inclination. If you can not pick up the finished structure, you can make the stairs to order. Pricing policy of manufacturers allows you to purchase your favorite model in a different price range, depending on the cost of the material.

The main components of the stairs

The structure of a typical wooden staircase.

We have already said that a continuous series of steps is called a march or march span. The platform separating the marches is called turning. The steps consist of two parts:

- horizontal - steps,

- vertical - risers.

The steps are zabezhnye, rectangular and frieze. Zabezhnye steps have a special form that allows you to turn the stairs without a turntable. Frieze steps are the lower and upper steps of the floor.

A monolithic wooden beam on which steps are fastened is called a kosour. The side beam connecting the steps is a string. Balusters are called posts for railings.

Independent production of stairs

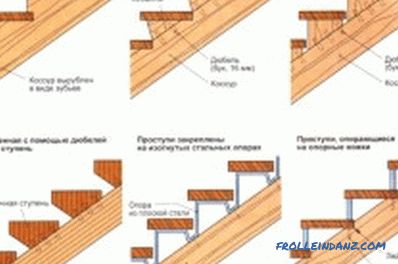

Construction of various types of steps.

So how do you make the stairs yourself? To do this, observe the following stages of design and execution of work:

- calculation of the size and angle of inclination of the future structure;

- determination of the optimum step width and height of the riser;

- choice of material ;

- cutting steps;

- marking for the string;

- mounting.

Calculation of dimensions and angle of inclination

To determine the height of the slope, it is necessary to install a long plank from the staircase on the second floor to the place where the staircase will start from. On the top floor, the board is set horizontally with a level and secured.

The angle of inclination of the structure should be in the range of 30-45 degrees.

Calculates the slope of the stairs.

A large tilt angle will make climbing and descending difficult and will not provide the required safety. A too flat staircase takes a lot of space. The width is determined by the area that the owners can allow to take under it. It is worth noting that the wide staircase is more comfortable and safe when walking.

We proceed to the calculation of the height and width of the steps. The height of the riser should be in the range of 120-200 millimeters. The optimal value is 140-170 mm.

The desired step width is 340-370 mm. In this case, the ratio should be observed: the higher the risers, the narrower the step. But at the same time the width of the step can not be less than the height of the riser. When performing the calculation of the width of the step, it should be remembered that it has a protrusion of twenty to forty millimeters above the risers.

Choice of material

The final cost of the finished product and the aesthetic appearance of the room depends on which material is selected for the construction of the stairs. Oak, maple, and pine are used as wood for the steps. For the manufacture of balusters will require a tree of a height of fifty centimeters or metal rods. You can order to carve curly balusters of wood or forge openwork metal. For the manufacture of railings, you can take the wooden bars, grinded milling, or block-house. In the absence of experience in the processing of wood or the necessary equipment, cutting and grinding steps, railings and balusters can be ordered. And installation of the product can be carried out independently.

Marking kosura and cutting steps

Marking kosura.

First of all, it is necessary to determine the method of attaching the kosour to the upper floor. There are two ways of mounting:

- fasten the kosour at the top so that the last step is flush with the floor of the upper floor;

- fasten the kosour at the bottom to the beam so that the floor of the upper floor serves as the last step of the ladder.

Then we proceed to marking the kosour. From tools for marking you will need a metal square and a curve. Let's make a piece: on a sheet of cardboard or other suitable material, measure the height of the riser and the width of the step, taking into account the thickness of the step itself and its protrusion above the riser. Using the template, we perform the marking of the kosour along the entire length.

After marking, we proceed to sawing out the slots for the steps and the steps in the kosour. To do this, use a circular saw, completing sawing hand saw. This work must be carried out with special care so as not to go beyond the limits of the marking, otherwise the steps will be too loose in the track, which will lead to a loosening of the structure.In the same way we prepare the remaining kosoura. You should not save on the amount of this element, since it determines the rigidity of the ladder, prevents deflection of the steps and, as a result, ensures the durability of the whole structure.

Structural Installation

First, a support pole is installed. Then using screws and liquid nails to the wall (beam) are mounted skouras. At first, turning stages are fixed on them.

The next stage is the installation of the risers and steps. They are fastened to each other and kosour using screws. Caps of self-tapping screws carefully deepen in a tree.

After the installation of the steps, the side open part is covered with a string. Now you can begin to install balusters and railings.

Materials and tools for assembling ladders

- bars;

- boards;

- balusters;

- nails;

- screws;

- brackets;

- saw, grinder with nozzle;

- hammer;

- drill, screwdriver.

The space under the stairs will be equipped with lockers for storing various things or arranging a dressing room. And you can put a sofa, chairs with a coffee table - you get a secluded corner rest. Now you know how to make the stairs yourself.