Building a house is a very crucial step, since everything must be done qualitatively and reliably, because the future construction must serve for many years. It is important to think over the details and first decide what material will be made of housing. The first to come to mind are popular materials, such as brick or wood, but another option should be noted that will give odds to both - it is arbolit. There are many advantages to the material and in this article we will talk about this in more detail. In order to save, many build a house of arbolita with their own hands, and in this case it is necessary to follow the recommendations of experts.

What is arbolite

Composition of arbolite

Composition of arbolite

Perhaps some of you are first learn about the existence of such a building material. But today, more and more buildings are made from it. And this should not be surprising, because it has many positive aspects.

Arbolit is a type of lightweight concrete. It has a coarse-grained structure, and wood chips are 80% of the entire base. The composition of wood concrete consists of three main components:

- organic filler (chips, sawdust, chips);

- portland cement;

- modifying additives.

Modifying additives in the composition improve the technical characteristics of wood concrete. Thanks to them, the material can have the following properties:

- improved bactericidal properties;

- acceleration of the setting process;

- regulation of the arbolite porosity.

Sale of wood concrete

Sale of wood concrete

You can buy material in specialized stores. It is sold both in blocks and in monolithic panels. It is noteworthy that in order to save arbolit can be made independently, for example, in garage conditions. All you need is to prepare all the components.

Advantages and disadvantages

Advantages and disadvantages of wood concrete

Advantages and disadvantages of wood concrete

When you make arbolite, you you actually recycle waste woodworking organizations. Due to its composition, arbolit is a fairly lightweight material, so the future construction will not have much weight. In addition:

- The complexity of the entire masonry process will be reduced.

- Reduced costs for the use of special equipment.

- Installation work will be easy to do.

- It is not necessary to make the foundation powerful.

A wall made of wood concrete is less subjected to deformation processes during house shrinkage. Because of this, you can not be afraid that later there will be cracks and other damage.

Arbolite is easily cut

Arbolite is easily cut

It should be noted that the positive qualities of wood concrete weight:

- Low thermal conductivity, due to which the material holds the warm air in the room well and prevents the penetration of both cold air in winter and warm in summer.

- Increased frost resistance, which makes it possible to build buildings in regions with a harsh climate.

- Fire resistance, due to which the material will not burn, despite the wood content in the composition.

- Good adhesion. This property helps to combine wood concrete with any building materials that perfectly adhere to its surface.

- Durability and durability. This indicator is one of the main ones, since during the construction of any building everyone wants to achieve precisely this goal. The blocks of wood concrete are quite strong, so you can safely build a house of 2-3 floors. By the way, arbolit will not rot and fungi and various microorganisms do not appear in it.

- Porous structure providing excellent sound insulation.

- Low weight.

- Absolute environmental friendliness.

- Low price.

The material has its own small minus - low moisture resistance. Wood concrete is hygroscopic and easily absorbs moisture from the environment, so when working it must be isolated from moisture.

All this makes wood concrete an ideal option for building your home.

Procurement of material

If you want to build an arbolit house, you need to immediately decide how to do it - to build it from blocks or to pour a monolithic house from arbolit . Next is another choice - buy the material or make it yourself. If you have the funds and decide to buy blocks, just prepare a place for them under a shed for storage. Independent production of wood concrete is also welcome, all you need is to prepare the material in advance.

Wood chips are the basis for wood concrete, but they should not be too small - at least 4 * 5 * 0.5 cm. This is due to the fact that the tree absorbs moisture very quickly. If the chips are small, when blended with cement, they simply lose their properties.

Preparation of raw materials should be carried out in the following sequence:

- Purchased waste from the sawmill should lie in the open air for 3-4 months.

- After that, they need to be treated with a solution of limestone (2.5 kg per 150 liters of water).

- 3 days, the chips should be stirred.

- Wait until the limestone mortar dries.

The following can be used as additives for wood-concrete mixture:

- aluminum sulphide;

- slaked lime;

- calcium or aluminum chloride.

After all the steps, it is time to start mixing the wood concrete mortar.

Mixture preparation

To prepare 1 m 3 of solution from wood concrete, you will need the following components:

- 300 kg of wood chips;

- 300 kg of portland cement;

- 15-35 kg of chemical additives;

- 350-400 l of water.

Mixing container Kneading is best done in a container with low sides, a large trough would be ideal. In another case, you can use a concrete mixer. To make arbolitovy blocks, you will need forms. They can be made of wooden planks, sheathed with plywood or sheets of metal. To make them bottom, use linoleum. For the convenience of further work, make pens.

Mixing container Kneading is best done in a container with low sides, a large trough would be ideal. In another case, you can use a concrete mixer. To make arbolitovy blocks, you will need forms. They can be made of wooden planks, sheathed with plywood or sheets of metal. To make them bottom, use linoleum. For the convenience of further work, make pens.

Forms before pouring should always be moistened with water or lime. And the bottom, which is made of linoleum, will need to be periodically changed, as it will wear out.

Now you can knead the solution. To do this:

- Pour the sawdust and additive into the trough or concrete mixer.

- Cover everything with water and mix well. If you do it manually, use a garden hopper instead of a shovel for mixing.

- Then add portland cement and water.

- Then everything needs to be thoroughly mixed again.

- Treat the forms with lime.

- Pour the mixture over the forms and thoroughly tamp it.

It is not necessary to pour the solution into the form flush. Leave 2-3 cm of space from the edge of the form. From above arbolit should be covered with a plaster mixture and leveled with a spatula. It is necessary to keep the block in shape throughout the day, so that it will clutch and become stronger. The next day, the blocks need to be removed and put under a canopy. There they will wait in the wings for 2-3 weeks, only after that they can be used for construction works.

If you plan to make the walls monolithic, gradually filling them, the mortar should be kneaded immediately after the foundation has been made and everything is ready for the walls to be filled. The technology of mixing the solution is the same.

So, the material for building a house has been prepared, then we will look at how to build a house. If you already have a house plan and drawings, then the first step is to make a foundation - the basis for the future house.

Building the foundation

Foundation

Foundation

The main advantage when working with arbolit is its low weight Therefore, the foundation for your construction can be any:

- pile foundation;

- strip underdeveloped foundation;

- tiled foundation;

- columnar foundation.

It is important that even if the building progresses (which cannot be avoided), the walls of your house will not crack. This is possible due to the unique properties of the wall blocks of arbolita: they have high resistance to fracture. Due to this, you can choose any type of foundation in order to save and ease the arrangement. Most often, preference is given to bored piles and a tapered shallow foundation.

Shallow-footed tape foundation

Shallow-footed tape foundation

Briefly about how to make a strip foundation:

- Prepare the foundation, mark the plot according to the house plan.

- Dig a trench under the foundation.

- Seal the bottom by making a pillow 5 cm high out of rubble or sand and tamping it down.

- Optionally install reinforced mesh.

- Then make the formwork. Take care that no cracks form.

- Now you can pour concrete, tamp it and expel the air.

- Everything is leveled with a trowel and left to dry completely, which will take 1 month.

The principle of waterproofing stickers

The principle of waterproofing stickers

Since the wood concrete from which walls will be erected has low moisture resistance, the foundation necessarily needs waterproofing. First, the base must be raised 40-50 cm above ground level, or make a substrate of a brick in half a meter. Secondly, the foundation should be smeared with bitumen and lay 2-3 layers of waterproofing (for example, roofing material).

Briefly about how to make a pile foundation bored:

- Calculate the future foundation (depth, height above the soil, frequency of piles).

- To mark a site proceeding from calculations.

- Make wells under the piles.

- Make formwork and make a pillow.

- Reinforce the future foundation.

- Install piles and carry out waterproofing works.

- Pour the concrete into the wells.

Masonry walls of wood concrete

When the selected foundation is ready, you can start building walls. If you have already made brick laying, it will be easy for you to work with wood concrete as well, since the principle of operation is the same. The order of work is as follows:

- Masonry starts at the corners. It is necessary to set the corner blocks perfectly evenly, since the evenness and quality of the future wall depends on it. For these purposes, use the construction level.

- Further, a cord or a fishing line is pulled between the corners. It should run along the edge and be well stretched. The following blocks will be aligned on it.

- After this, the blocks are laid directly. They need to be adjusted to the level of the fishing line and make the same seam, no more than 1 cm.

- Having finished the first row, the second one does the same, only with the bundle you have chosen.

- If the blocks need to be sized, they can be cut with a stone saw.

In order for the laying to be reliable and of high quality, some points should be taken into account:

- In order for a house made of wood concrete to display its thermal performance by 100%, cold bridges should not be allowed to form. They will contribute to a large loss of heat. To remove them, use the method of breaking the seam with a wooden plank when laying. It should be a section of 12 * 12 mm.

- Since arbolit absorbs moisture, it is necessary to moisten them with water before installing the blocks. Otherwise, it will absorb water from the cement solution. Another option is to make a more liquid solution.

- If it is necessary to build a house with a non-standard design, the blocks are processed immediately on site with a stone-cutting saw. If there is no desire to spend a lot of time, figured blocks can be ordered from specialized firms, but it will cost more.

Solid walls

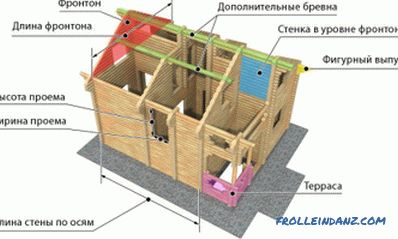

Monolithic house of wood concrete

Monolithic house of wood concrete

If you planning to make monolithic walls, you need to make a solution before starting work. The technology is similar to conventional concreting. Formwork is installed on the foundation. Its height should be 60 cm maximum. It is important to ensure its sufficient reliability and durability so that it can withstand the load of heavy wood concrete, therefore it must be well combined and strengthened.

As a reinforcement for wall stiffness, you can use board frames, which are installed vertically in increments of 120-150 cm. Thanks to the framework, a deformation seam is created that promotes even load distribution. Boards must be treated with antiseptic.

It is better to pour concrete with a layer of 50 cm and no more so that the structure does not collapse under the weight. Do not bury the solution to the brim. After that, everyone tightly tamped and wait for drying (usually it is 2-3 days). As soon as the mortar set, the formwork is dismantled and rises above to fill the next layer of wood concrete. The formwork should be removed carefully. All work is done until the desired height of the building is reached.

Finishing of arbolit walls

Finishing of arbolit walls with stone

Finishing of arbolit walls with stone

Thanks to the rough surface arbolit walls have good adhesion (adhesion to any surface). This means that you can plaster the walls immediately, without additional preparation of the walls.

Any material can be used as an exterior cladding material:

- siding;

- lining;

- brick;

- wood (block house);

- front paint.

Inside the wall of the house you can decorate everything that your soul desires. There is only one rule - inside the room humidity should not be more than 75%.

Roofing

Installation of floor slabs

Installation of floor slabs

When the box of a future building is done, care should be taken of the roof over your head. The main task is to distribute the load correctly throughout the whole structure. To solve it, you can resort to one of two options:

- Make a concrete tie, which is reinforced over a layer of arbolit.

- Install a wooden block on the blocks (mauerlat).

The second option is most often used. Beams must be treated with antiseptic and installed with a step of 60 cm. The section of the beams is 10 * 20 cm. To make the rafters, use boards with a cross section of 20 * 5 cm. The rafters are covered with waterproofing material.

The ridge is made from a bar of 5 * 5 cm in size. It must be attached to the rafters. For a batten, take a board 15 * 3.5 cm and fix it in steps of 25-30 cm. It remains only to put the roofing material. It can be slate, metal tile or corrugated flooring.

This house is built of wood concrete

This house is built of wood concrete

So, you can easily make your own dwelling out of arbolita.Moreover, such a house will be warm and durable.

Video

In this video, the author shares his personal experience, telling how he built a house of wood concrete himself:

Photos

Construction of a home from arbolite

Construction of a home from arbolite

The box of the house is covered with a roof

The box of the house is covered with a roof

Combined wood concrete house with a veranda

Combined wood concrete house with a veranda

Another combined option

Another combined option

A house made of arbolite of complex construction

A house made of arbolite of complex construction

Woodblock House

Woodblock House