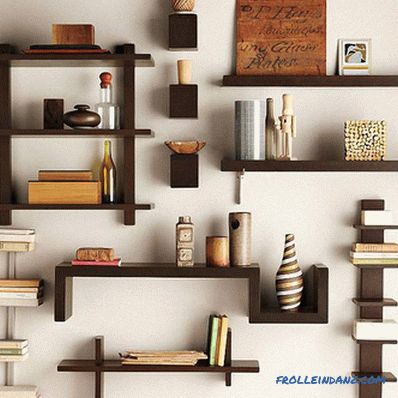

Self-made shelves allow efficient use of space and create an individual interior. Home craftsmen are not limited in their imagination in the choice of form and material, but we must not forget about reliability. Among the popular materials for shelves: glass, wood, drywall, plastic and chipboard. Working with them does not require the purchase of special tools, and the result can become a highlight in the decor of the room. Consider how to make shelves on the wall.

Classification by design and placement

Classic

Classic

All products can be divided into several types:

- Classic Wall - a common option, characterized by simplicity of design and mounting on the wall using corners, screws or other means. Such a regiment is easy to do yourself.

-

Suspended Suspended - the product is attached to the ceiling and held by cables or chains.

Suspended Suspended - the product is attached to the ceiling and held by cables or chains. - Corner shelves differ from the classic one at the same time on two walls, most often this design is used in the bathroom.

- Floor - the design does not have a wall mount, it is placed on the floor and rests on legs or a solid surface.

- Open or closed shelf design - in the first case its contents are accessible for review, and in the second it is hidden behind a glass or wood door.

- Decorative shelves are made without taking into account the shape of any material, their main purpose - interior decoration.

Wall shelves made of plasterboard

Wall shelves made of plasterboard

Material selection

Deciding on the choice of material for the shelf, you need to take into account its purpose.

Plastic. For use in the utility room or on the balcony, you can use plastic, inexpensive and moisture-resistant material.

Drywall. A common option for the bedroom and living room - a shelf-niche of plasterboard, giving the interior originality. In the manufacture of shelves in the bathroom, use moisture-proof plasterboard, and the outer surface is trimmed with ceramic tiles.

Glass shelves in the bathroom

Glass shelves in the bathroom

Glass. The material is able to decorate any interior due to its lightness and transparency. Working with him requires caution and care. In the bathroom it is better to use glass in combination with stainless steel.

Wooden shelf for the kitchen

Wooden shelf for the kitchen

Wood, as well as chipboard and MDF are suitable for any design. It is easy to work with a tree, it is durable and attractive. Such shelves are appropriate for any room design style. For self-production is the best option.

Making wooden shelves

Classic rectangular shelf

Classic rectangular shelf

Suppose you want to make shelf, to get a comfortable place for books. For work you will need:

- boards of 20 * 200 mm;

- plywood sheet;

- wood screws;

- varnish, stain, or paint;

- pencil and tape measure;

- drill;

- hacksaw;

- level;

- grinder or abrasive paper.

Processing the boards with a grinder

Processing the boards with a grinder

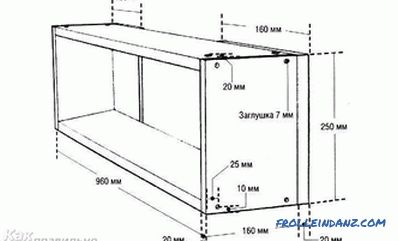

A classic rectangular shelf with sides and top will be made. Size of construction: width 200 mm, length 1000 mm, height 290 mm.

Example of drawing a hinged wooden shelf

Example of drawing a hinged wooden shelf

The first step is the drawing of the future shelf, all dimensions are marked on it and location of parts. The product consists of two parallel boards with side parts inserted between them, the back part is covered with plywood.

- The saw is sawed off two boards of 1000 mm and two of 250 mm each. A blank of 1000 * 290 mm is cut out of plywood.

- Boards are machined with a grinder or sandpaper until smooth.

- Preparations are varnished, painted or painted.

- After the parts have dried, the assembly begins: on the lower and upper parts, departing from the end 10, and from the edge of 50 mm, points are marked. Using a drill, 4 holes are drilled in each board.

- The side parts are attached to the bottom part and screwed with screws into the prepared holes. The upper part is fixed as well.

- A sheet of plywood is attached to the ends with small nails.

- At the ends of the side parts brackets are placed and fastened with screws.

- On the wall, using a level, marks the place for fixing the shelf. The distance between the brackets is measured and deposited on the wall. Screws protruding 5–7 mm protrude at these points, and a shelf is hung on them.

Plasterboard

Gypsum Board Shelf with Illumination

Gypsum Board Shelf with Illumination

Design of drywall can make a room look different, especially if it is a multifunctional structure between walls. There are books, vases, souvenirs, frames and even a TV set on it. The addition of shelves with backlighting from spotlights or LED strips will make them more spectacular and more attractive.

To manufacture the structure, you need:

- UD guide profile;

- self-tapping screws;

- drywall;

- reinforcing mesh;

- putty;

- level;

- screwdriver;

- construction knife;

- plumb, tape measure; pencil;

- scissors for metal or Bulgarian;

- spatula.

The intermediate stage of manufacturing a shelf made of plasterboard

The intermediate stage of manufacturing a shelf made of plasterboard

Before mounting the frame, a drawing is drawn up, All sizes and locations of shelves are applied.

- The wall is laid out according to the drawing. All marks are applied by level, the reliability of the design depends on it.

- Holes for dowel-nails are drilled in the guide profile. The profile is screwed to the wall along the marked lines. For stability, the frame is attached to the ceiling and floor.

- The bulkiness of the structure gives the installation of jumpers from the CD-profile. The joints are fastened with crabs - metal fasteners for drywall.

- In the manufacture of the TV shelf, the usual profile is replaced with a metal angle.

- After the frame is assembled, if backlighting is provided, wiring is laid.

- The dimensions of the shelves are transferred to drywall, which is cut by a construction knife.

- The frame is sheathed with cuts, which are fastened with self-tapping screws. For shelves with a high load, a material with a thickness of 18 mm is used; for ordinary ones, 12.5 mm is enough. For mounting fixtures in drywall, holes are cut with a special nozzle on the drill.

- All joints are covered with a reinforcing mesh and coated with gypsum putty. After the seams have dried, the entire surface is covered with starting putty. Smooth ends helps to create a special galvanized profile. Finishing is completed with finishing putty and painting.

Flat ends are created with the help of a perforated angle

Flat ends are created with the help of a perforated angle

Any shelf made by yourself will become not only a functional subject, but also a reason for pride.

Video

This video shows how to install shelves with hidden fasteners:

And here you can see instructions on how to make a wooden wall shelf of interesting design :