All people at least once during their life faced with the fact that they lack the furniture in the house. Of course, this task can be solved by purchasing additional cabinets, bedside tables, etc. But the store does not always have furniture that meets the necessary needs and has an affordable price.

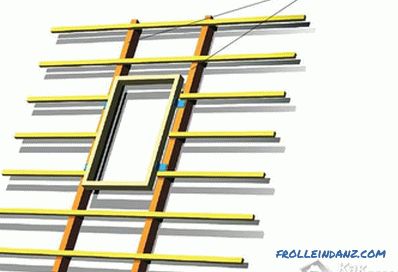

Wooden bed frame scheme.

Therefore, in such cases, you can make furniture with your own hands and right at home.

Furniture manufacturing

Wood furniture in home conditions is assembled in several stages:

- material preparation;

- manufacturing of component parts;

- assembly.

But at the very first stage, which is fundamental, you need to decide on the design of the product and its location in the room. After that, you need to decide on the required size. In these sizes, it is necessary to determine not only the dimensions, but also the dimensions of the internal parts (shelves, drawers, etc.), as well as their number.

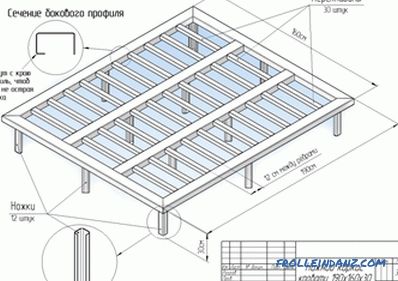

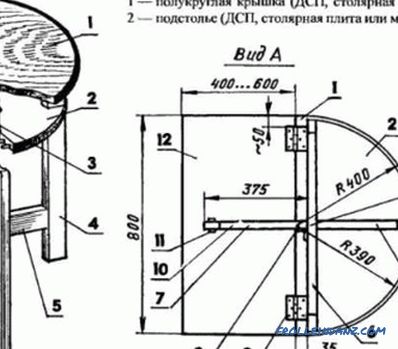

Wooden table arrangement.

The next step is to decide on the desired color of the facade covering. Currently, there is a fairly large range of color solutions, but most often the furniture made of wood is made from flowers that imitate natural wood species. Among them, the most common are oak, cherry, walnut, beech or maple.

After the decision has been made on which color to use, the shape of the furniture has been determined and all its dimensions have been calculated, it is possible to proceed with the manufacturing process.

To do the work, you need the following tool:

- electric jigsaw;

- tape measure;

- pencil;

- screwdriver set;

- screwdriver.

Initially, you need to make markup on the purchased chipboard sheets. This should be done so that the material consumption is as economical as possible. This can help the computer, where you can perform the necessary layout of parts of furniture.

After that, you can start cutting parts from which wood furniture will be assembled. To do this, you can use an electric jigsaw. Wood furniture in the home should be cut very carefully in order to avoid chips on the laminated layer. To do this, stock up on special files for laminated chipboard.

Selection of accessories

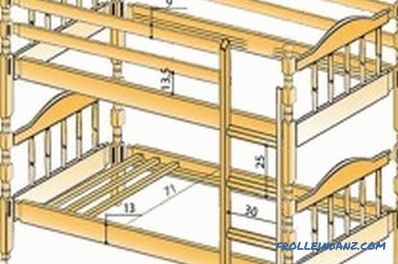

Drawing with the size of a bunk bed.

At the end of the sawing process, the finished parts of the future product will be obtained. Now you need to stock up on the necessary hardware. If it is a wardrobe or nightstand, then when selecting hinges, you should take into account which way the doors will open. The cabinets must immediately provide ventilation and possible lighting options. If you plan to use wood furniture for storing products, then you need to provide it with the necessary devices that will support the specified parameters. Fittings in this case should be made of aluminum.

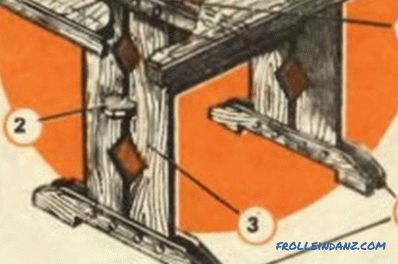

It is better to use wooden bars or metal corners as shelf fasteners. To the body they should be fastened with screws or dowels-nails. Very beautiful appearance of wooden furniture will give shelves with a metal base.

In the event that a storeroom is being assembled, you need to stock up on metal pipes, the length of which will be equal to the distance from the floor of the room to its ceiling. After that, they need to fasten additional transverse tubes that will create the frame of the product.

It should be borne in mind that the finished product should not take up much space in the room. There should always be enough free space, both inside and outside of it.

Assembling wooden furniture

Having prepared all the necessary structural elements, you can begin assembling it. To do this, you first need to make holes in the body with a small drill. They are performed by pre-applied markup. The depth of these holes should be 12-14 mm, which is due to the thickness of the chipboard sheet. The diameter of the prepared holes should be small, because they will help facilitate the process of fastening and at the same time retain its strength.

After completing this procedure, it is necessary to mount all the elements (shelf supports, drawer guides, etc.). Then you need to start fixing door sheds or guides, if it is a compartment door. On the hinges you need to hang the door leaf. Next, you need to perform the adjustment of the doors so that they do not touch each other.

Furniture assembled at home may have one drawback - unaesthetic edges. After cutting, the end of the sheet does not have a laminated layer, which makes the appearance of the product ugly. But this can be easily fixed. You need to stock up on the edge, the color of which coincides with the color of the laminated chipboard layer. You can glue it with an iron. To do this, attach an edge to the end of the workpiece, and put a rag on top of it.On a rag it is necessary to iron the iron, at the same time doing strong pressure. Such actions will allow good glue edge. Excess of it, which will remain at the edges, can be cut with a stationery knife.

The assembly process is completed by fastening the desired handles. To do this, you need to make through holes in the required places, and on the inside - their countersink. This will help drown the caps of the mounting screws. Now the furniture can be considered completely ready for use.

If everything is done exactly according to the project, then difficulties in how to make the furniture yourself should not arise. To do this, you need to have the necessary tools and minimal skills to use it.

Didn't find the answer in the article? More information on the topic:

-

How to make furniture yourself

How to make furniture yourself. What are the materials, and what is their difference? Variants of the drawings, as well as a description of the manufacture of an example. What else you need to know when deciding to do this kind of work?