The ability to use alternative energy sources often attracts people. Therefore, attempts to get energy from the power of nature were made before the Common Era. In this article we will explain how to make a wind generator with your own hands at home (from scrap materials).

The wind generator can be used for the following purposes:

- room lighting,

- television or audio equipment connections,

- household appliances or office equipment connections.

Most often, a wind generator in a country plot cannot be the only source of energy, unless it is installed in a site not in one instance.

Scheme of a wind generator

Sometimes you can see a whole network of wind turbines that convert wind energy into electrical and accumulate it into prepared batteries. Such sources of electricity can be used purposefully, to operate only one household appliance, or to save them as a backup in case of disconnecting the main source of electricity.

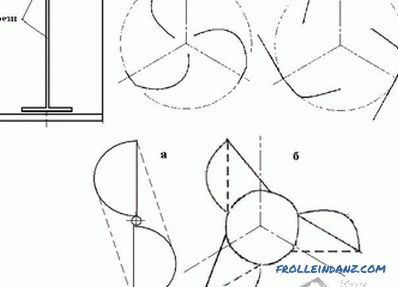

The main difference, which allows to distinguish two types of wind generators, is in the form of a propeller: propeller or sailing.

Sailing

Sailing

Before you make a wind turbine, you need to decide for what purposes it is needed. The more difficult tasks are set for such an energy source, the more difficult its design will be.

Propeller

Propeller

The structure of the wind generator includes:

- wind wheel with blades;

- gearbox (mechanism that converts and transmits torque);

- mast on which to install;

- battery;

- inverter (mechanism for conversion of DC power from AC to AC).

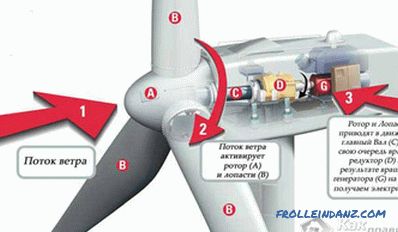

The work of the wind generator is as follows: the wind rotates the wind wheel with blades with its energy, and the torque is transmitted through the gearbox to the generator shaft.

The principle of operation of the generator

The principle of operation of the generator

When self-fabricating an alternative energy source, you should pay attention to the rotary or vertical type such a device - it allows you to get more energy due to the effective impact on it of wind energy.

Beforehand it is necessary to prepare:

- The generator is 12 V, the battery is 12 V. The most commonly used batteries are acid, gel or armor-made - they withstand the maximum number of digits - from 250 to 1200 cycles . It is not recommended to use a car battery due to the fact that it does not withstand even the full 100 discharges of the battery, which means that it will fail faster and require replacement.

- Rotor size from 1.5 to 2 m.

- Metal barrel or volume bucket for the manufacture of blades.

- Two relays - for charging the battery and for charging the lamp (an ordinary incandescent lamp, with a capacity of 25 to 150 watts - it will show that the wind generator is working correctly).

- Switch.

- Voltmeter.

- Distribution box.

- A mast up to 10 m high (for example, a metal pipe or a PVC pipe with a diameter of at least 160 mm, designed for sewage, or a pressure pipe. Pipes for simple sewage will not work, as they are too thin and fragile).

- Stranded wires (2-3 cores) with a cross section of at least 4 mm².

- M6 bolts, corresponding nuts and washers in the amount of 4 pcs.

- Stainless wire with a diameter of 0.5 to 1 cm.

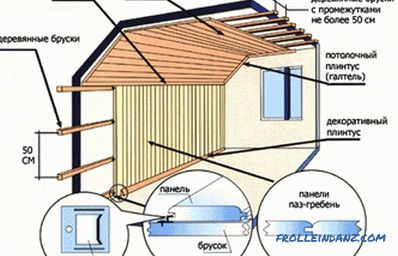

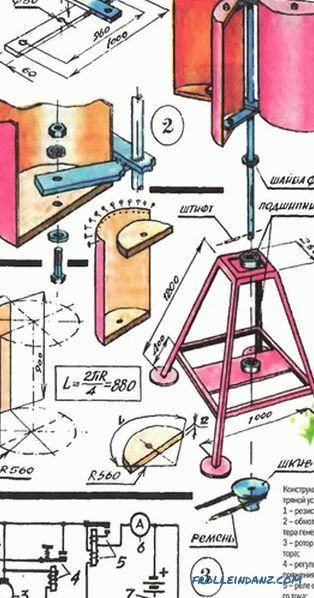

Drawing

Drawing

From the tools, you will need various wrenches, a drill, a screwdriver and pliers.

Creating and installing a wind generator

Wind installation

Wind installation

- Initially required to make a rotary type wind generator. The diameter of the rotor is directly dependent on the average wind speed during the year. The rotor is a cylinder-shaped structure whose blades look like arcs in section. For the manufacture of used sheet metal, curved in the form of an arc. Blades are attached to the upper and lower discs with rivets and corners. To the lower disk is required to attach the flange. It is designed to attach the blades to the rotor.

- It is necessary to take a bucket, mark it in 4 pieces with a pencil, carefully cut it up to the end. In the bottom to prepare the holes for the bolts so that the axis of the generator was clearly in the center of the bottom of the bucket. Blades made of bucket walls should be bent at the required angle, depending on the direction and intensity of the wind. The greater the bend of the blades, the greater the speed of rotation of the device, however, the device can fail faster.

- After which the modified bucket, namely its bottom, needs to be attached to the pulley with the help of bolts.The joints must be chosen very carefully - improper fastening will lead to the need to constantly adjust the position of the blades and adjust the rotation, which is difficult to do on the wind generator already installed on the mast.

- Wires are required to be connected to the generator. If the wire is not multi-colored, it is desirable to indicate the position of the wires and their marking with multi-colored tags.

- After connecting the wires to the generator, you must assemble the circuit in the junction box. The generator prepared in this way should be attached to the mast, after which the wires should be attached both to the generator and to the mast. The generator must be connected to the circuit, and after it the battery. The load must be connected using wires with a cross section of at least 4 mm².

Installation of the mast

The mast for the wind generator must be carefully secured. To do this, prepare a hole in the ground slightly larger than the diameter of the mast. The depth of the hole should not be less than 50 cm. Laying a gravel-sand pillow on the bottom with a layer of 10 cm, it must be tamped carefully and spilled with water. After that, the cement mortar must be poured into the hole by 10 cm. It is necessary to install a mast into it and, having fixed it, fill the hole with concrete mortar until the end.

In the case when it is necessary to increase the efficiency of the wind generator, the mast length should be increased by 30%. The high mast allows not only to increase the amount of wind energy, but also to eliminate wind interference in the form of buildings or trees.

Video: propeller wind generator

And this is an example of a propeller wind turbine to give: