House building works require a huge investment of strength, finances and maximum responsibility. The main stage of construction work is the installation of the foundation.

In order for the foundation to become a reliable and durable foundation of the structure, it is necessary to take care of its waterproofing. This will protect the main part of the building from the adverse effects of external atmospheric factors.

Types of foundation waterproofing

Types of waterproofing

Types of waterproofing

In the field of construction there are two types protect the foundation from moisture: horizontal and vertical. At installation of the base one of them is often used.

If the building does not provide for a basement, then only horizontal insulation is allowed.

Horizontal waterproofing

Horizontal insulation device To know how to waterproof the foundation correctly, you must decide on the ones used for this materials. For example, roll materials are widely used for horizontal waterproofing.

Horizontal insulation device To know how to waterproof the foundation correctly, you must decide on the ones used for this materials. For example, roll materials are widely used for horizontal waterproofing.

Installation of horizontal foundation insulation is carried out taking into account the following technological features:

- its installation is performed at the lower point of the basement floor, just above the blind area and at the level of the connection of the base of the housing to the basement floor;

- if there is no basement, then the material for waterproofing creeps in several layers over the pavement around the perimeter of the foundation;

- when choosing a material, make sure that it has a base that does not rot.

Vertical waterproofing

Vertical technology

Vertical technology

Vertical insulation has several Species:

- Penetrating protection against moisture. It is made of cement mortar with quartz sand. The applied mixture reacts with a concrete surface and in

Horizontal type ode of chemical processes crystallizes on the foundation. This method allows you to fill all the defects of the concrete structure and ensure its complete tightness.

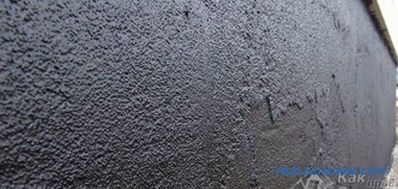

Horizontal type ode of chemical processes crystallizes on the foundation. This method allows you to fill all the defects of the concrete structure and ensure its complete tightness. - Base coating coating. This method involves the use of bitumen, polymer or rubber mixtures, or a mixture of cement and polymer. The bitumen used must be elastic, so the usual mixture in such cases is not permissible, because after solidification it becomes inelastic and cracks.

- Screen type of insulation. Screen waterproofing is popular under adverse conditions and complex soil properties, that is, under the strong influence of groundwater on the supporting structure of the building. This protection is made of special concrete clay panels, geotextile membrane or brick clamping wall. Such waterproofing is similar to a clay castle, which prevents water from penetrating to the foundation of the building.

- Pasting waterproofing waterproofing. This type of waterproofing is gluing a roll or film waterproofing material on the outer surface of the base. Water-repellent mastic is used as an adhesive base. This method allows you to protect the foundation quite effectively for a long time. However, it is more laborious, since it requires thorough preparation of the surface, by leveling it, priming it, applying mastic, re-priming and completely drying it in a natural way. Only after these procedures, you can glue the material for waterproofing.

Range of waterproofing materials

Packaging in rolls

Packaging in rolls

Insulation with roll materials In order to protect the surface from moisture, you can use a variety of materials, among which are often used:

Insulation with roll materials In order to protect the surface from moisture, you can use a variety of materials, among which are often used:

- Pasted roll waterproofing material. The main component in this insulation is bitumen, polymers or bitumen-polymer compositions. They serve as the basis for the production of soft roll and sheet materials. With the help of glued-on insulation, it is possible to perform protection of both vertical and horizontal type. At the same time you can be sure of durability and durability of the processed surface.

- Bituminous mastic. This method is used most often and has two varieties that differ in the method of application: hot and cold method of application. The second option takes less time and labor, since no heating of the material is required.

However, when using hot mastic, all the cracks and cracks on the surface of the foundation are filled much more efficiently.

The undoubted advantage of the treatment of the foundation with mastic is that there is no need to prepare the surface, which saves time.

If desired, you can choose mastic applied to a moist surface without pre-drying.

Materials for waterproofing

Materials for waterproofing

Do not forget that the independent implementation of waterproofing works should be carried out in accordance with hydrogeological conditions and soil properties for your area and home in particular.

Only in this case, the work will not be done in vain, and the waterproofing will fully comply with its functional purpose, and therefore the house will last as long as possible.

Video

You can also learn about waterproofing the foundation from the following videos: