For a long time, man attributed lightning to the category of natural phenomena that represent a certain threat to his peaceful existence. Nowadays, most private homeowners are well aware of the need for a lightning conductor to protect their home from lightning, which can lead to the following unpleasant consequences:

- a fire;

- electric shocks in house of people;

- mechanical destruction of buildings;

- the effects of electrostatic induction, which can lead to a short circuit and failure of household appliances.

The lightning rod

The lightning rod

Only after reading how to make a lightning conductor, you can protect your home and family from all the above troubles.

Construction

Lightning

Lightning

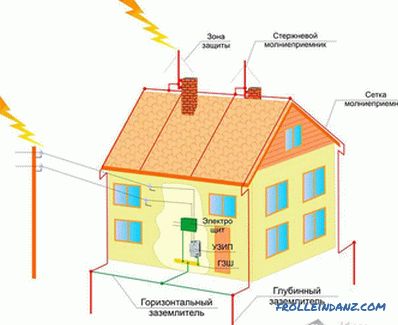

In accordance with current regulations, the design of the lightning conductor should contain The following elements are in its composition:

- interception receiver used to trap the lightning;

- current collector, by means of which natural electricity is dangerous to people and buildings;

- grounding conductor by means of which it is possible to establish reliable contact of the current lead with the soil.

Interception receiver

Rod interception

Rod interception

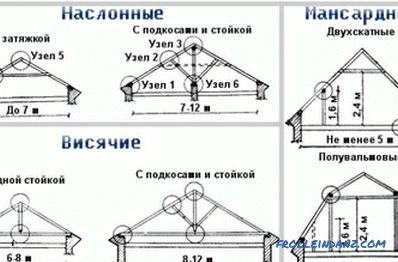

According to its design All practiced lightning protection systems are divided into rod, mesh and linear devices.

Mesh lightning receiver

Mesh lightning receiver

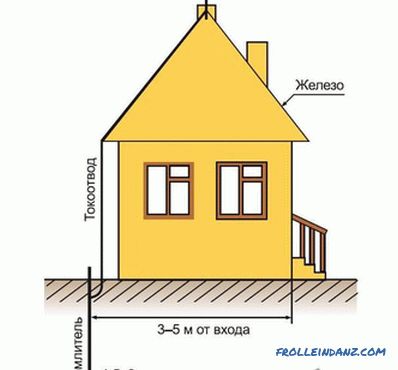

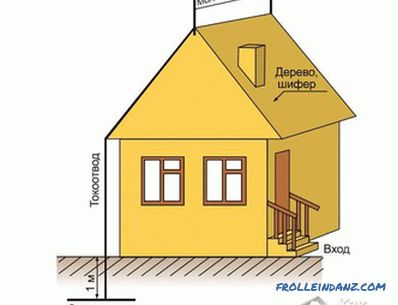

The core lightning receiver is usually made in the form of a metal bar having a length of 0.5 up to 2 meters. Linear receivers are a metal cable with a cross section of the core more than 5 mm. This cable is stretched along the ridge of the roof at a height of about half a meter from it and secured with special wooden clamps. In this case, both ends of the cable are connected to the grounding conductor by means of a current lead. Linear receivers are used to protect buildings, the roof of which is equipped with slate or wooden coating.

Linear interception receiver

Linear interception receiver

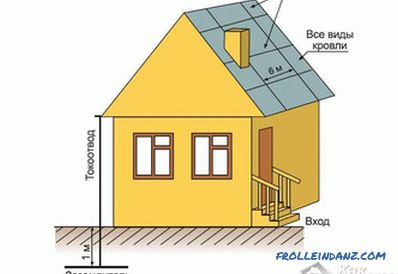

Mesh interception rods are made in the form of a grid, which is made of wire with a thickness of 6 mm with a size of cells from 3 to 10 meters. Such a grid is stretched over the roof at a height of half a meter and is connected to the down-conductor at several points at once.

Down conductor and grounding

Current lead

Current lead

A standard conductor is usually made of copper wire not less than 6 mm thick.

A set of earthing can be performed by a set of metal rods that are driven into the ground (to a depth of about 2 meters) in a place at a distance of at least 5 meters from the house. The rods driven into the ground are welded together and then connected to the down-conductor by any of the known methods (welding or bolting).

Selection of space for the grounding and its maintenance

Design of the lightning conductor

Design of the lightning conductor

Before you make a lightning conductor, you need to worry in advance about the choice of the place that is most suitable for arranging the earthing switch.

The fact is that it is possible to ensure reliable contact of metal rods with the ground only under the following conditions:

- soil moisture in the area of the grounding device should correspond to the value normalized for this device class;

- its chemical composition must comply with electrical safety requirements.

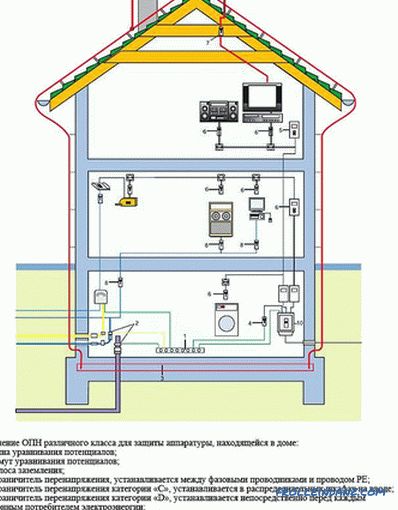

Application of surge arrester

Application of surge arrester

The drier the soil at the grounding site, the the worse his contact with the earth will be, and the more unreliable will the lightning removal system work.

In order to increase the contact with the soil (electrical conductivity), it is recommended to periodically moisten the soil using a special brine. In some cases, it is allowed to add ordinary table salt to the soil.

The maintenance of the lightning conductor is reduced to monitoring the reliability of its contacts and to visually inspecting the grounded part for the absence of the last rust and dirt on the surface.

Video

How to fix the lightning disposal system, see below: