Currently, the assortment of each construction store is replete with a huge amount of materials intended for the arrangement and installation of the gate. However, most developers prefer to use profiled, because it has a number of useful properties: durability, durability, aesthetics and affordable price. Raw materials are manufactured at the factory by the method of cold-rolled steel sheets, both sides of which are treated with a protective layer of zinc, which protects the surface from the harmful effects of the environment and premature destruction. In order to get acquainted with the presented material in more detail, as well as to answer the question of how to make a gate of corrugated flooring on your own, you should understand the features of its use and study the assembly technology.

Advantages of designs

The use of this material is due to a number of defining advantages. Of these, the following are recognized as essential:

- a long period of operation;

- a small proportion of the structure;

- a huge selection of colors and textures;

- there is no need periodic repairs;

- affordability;

- ease of installation.

Types of structures

Types of structures

Types of structures

Of the many options available the manufacture of the gate is to highlight two bright representatives:

- Swing - two doors, which diverge in opposite sides.

- Retractable - one web moving along the fence.

From the list presented, you should stop your attention in the second view, since it saves the surrounding space and is not whimsical to the effects of bad weather.

In order to build a sliding construction with your own hands, you need to correctly calculate the proportions of the counterweight and prepare a solid foundation. Otherwise, the gate can be deformed and fail.

Required tools and devices

Absolutely in any building measure the previous stage of the whole course of work is the selection of the necessary tool. To make a sliding gate you need:

- construction level and tape measure;

- a welding machine;

- a Bulgarian or a special hacksaw;

- a drill with a perforator and a set of bits;

- angle grinder;

- rubber mallet;

- kleplenik;

- wrench set;

- bayonet spade;

- tank for the preparation of concrete or cement mix.

Structural elements of the structure

Preliminary design and selection of the optimal dimensions of future gates, on which the total weight of the structure will directly depend, is a guarantee of quality and lengthy service life. Component parts are selected taking into account the total weight, width of the opening and the height of the facing profiled.

In addition, important elements of the sliding construction are cantilever accessories, which include:

- upper safety roller;

- lower rollers;

- end roller and stopper of the beam;

- a pair of catchers;

- a guide rail.

At the same time, an integral part of the gate is a robust frame that performs an important support function. In its manufacture, as a rule, metal profile tubes are used, the dimensions of which depend on the dimensions of the opening.

If there is a desire to equip the gates with automatic equipment, then do not forget to purchase an electric drive, remote controls, a beacon, and rails in addition to consumables. Also for fixing corrugated board you will need to use metal screws or roof rivets at the rate of 15 pcs. on the sheet.

Assembly technology

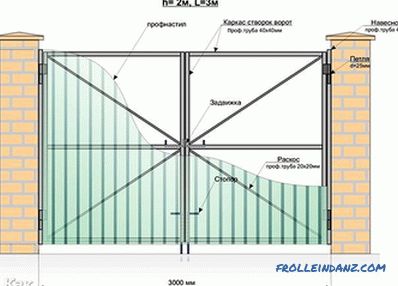

In order to properly construct the sliding gates, you should make an approximate design drawing in which to calculate the required materials and specify all components items.

Next, you should proceed to the preparation of sites for the base of the gate and support columns. In most cases, they are performed as a trench under the mortgage element and recesses.

To simplify this process, it is useful to select the existing retaining bases of the fence as reference pillars.

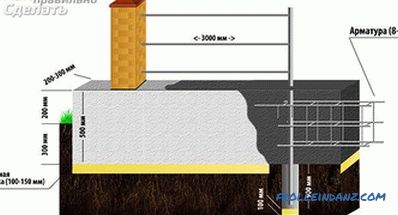

Construction of the foundation

The mentioned item includes the manufacture of the base for the supporting pillars and the gate itself. In the absence of the possibility of using supports from the fence, it is worth digging two holes with a depth not lower than 1.5 m. Then we install the pole into the recess and fix it with a concrete solution. The gate base provides for equipment of a trench with a width of 50 cm and a depth of at least 1.5 m.

An important feature is the location of the trench.It should be fitted close to the fence!

The construction of the foundation involves the use of a U-shaped metal product or channel, the length of which must coincide with the length of the prepared trench. At the same time, reinforcement elements are used to strengthen the base and give it the required strength. From the inside of the channel beam, segments of metal rods are welded to the depth of the trench, forming some backwater. The channel should be laid in such a way that its upper edge is flush with the road surface, and its ends fit snugly to the supporting posts.

Installation of support pillars

Installation of support pillars

Two roller carts are installed on the surface of the channel beam, which will carry out the sash movement . Do not forget about the placement of electrical supply cables. As a rule, all diagrams and drawings are enclosed with an electric drive.

Whenever laying a channel with welded reinforcement products, check their horizontal position with a building level. However, in order to avoid distortions and further deformation of the gate, control their position, which should clearly coincide with the sliding line of the future sash.

Making the frame

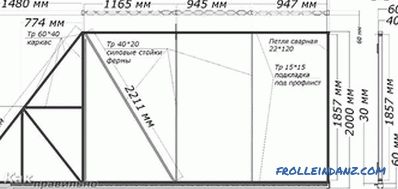

Before you start cutting and welding a metal profile, you must determine the dimensions of the inner frame and the frame. For the manufacture of the last component, it is necessary to use a profile with a cross section of 60 * 40 and a safety partition 40 * 20.

A guide rail is installed on the lower frame frame, and all elements are held together by means of a welding machine. Next, using rivets or metal screws, we fix profiled sheeting on the frame.

Do not forget about safety when dealing with metal products. To do this, you should purchase personal protective equipment glasses and gloves. A useful event will be pre-cleaning the surface of the pipe from rust and other dirt.

Final measures

At the extreme channel beam concreted in the foundation, you should fix the carriages and move them in opposite directions. Then they are put on a frame structure with a rolling roller and leveled at the construction level. After welding, it is necessary to grab a platform of carriages with a channel pointwise, once again check the verticality, horizontal position, the absence of distortions and finally boil all the way around the perimeter. Next, we fix the catchers, the upper safety and end roller mechanisms.

The fastening of the elements should be carried out so that the end roller of the leaf when closing the gate rolls over the catcher to remove the extra load from it.

Important features when installing

Neat gate from a profiled sheet

Neat gate from a profiled sheet

Some masters, ignoring the recommendations of professionals on the issue of how to correctly build a sliding gate, carry out the installation of carriages with welded adjusting pins. The use of these devices due to the ease of management and dismantling in case of failure.

A pair of unrecorded millimeters can later on lead to the need to re-drill the channel beam, adjust to new dimensions, etc. This will cost at least a couple of days and ultimately make you return to the proposed installation method.

In conclusion, I would like to note that when building a sliding gate, first of all, you should deal with all the subtleties of installation and study more than one arrangement scheme. At the same time, it is necessary to calculate the weight of the structure and correctly select all the constituent elements. For the implementation of the latter task, it would be useful to seek help from specialists who can not only point out mistakes in drawing up a drawing, but also advise the required equipment.

Video

The video tells in detail about the intricacies of assembling a door from a professional flooring:

Photos

On The photo shows various versions of the gates made of the profiled sheet:

Beautiful doors made of corrugated

Beautiful doors made of corrugated

Sliding gates

Sliding gates

Retractable from corrugated

Retractable from corrugated

Another recoiling option

Another recoiling option

Swing gates

Swing gates

Gates and wickets

Gates and wickets

Gates from a beautiful professional sheet

Gates from a beautiful professional sheet

Beautifully shaped

Beautifully shaped

At the cottage

At the cottage

Under the Tree

Under the Tree

With forging elements

With forging elements

View from the courtyard

View from the courtyard

Gate on hinges

Gate on hinges

Built-in wicket gate

Built-in wicket gate

Scheme

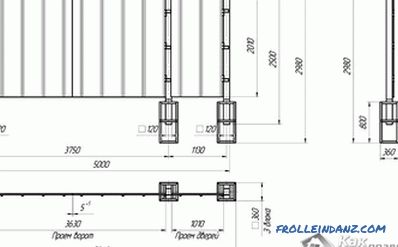

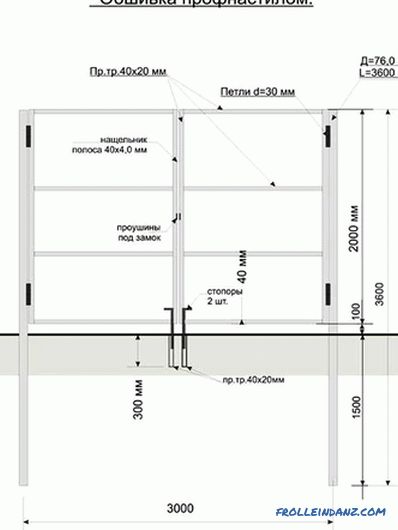

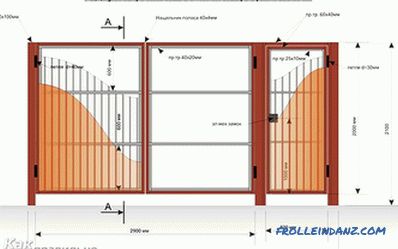

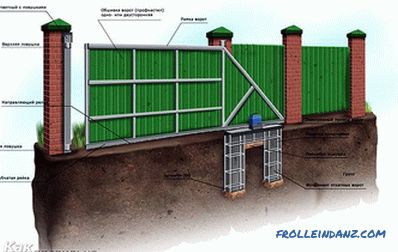

If you decide to make a gate from a professional flooring, then the provided schemes will help in this:

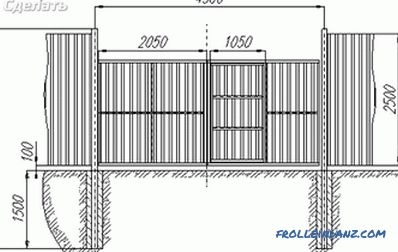

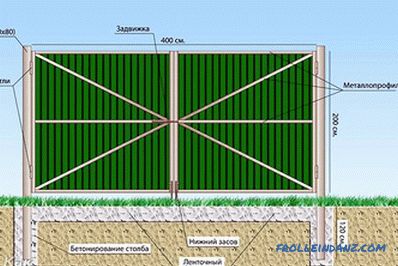

Design of the gate

Design of the gate

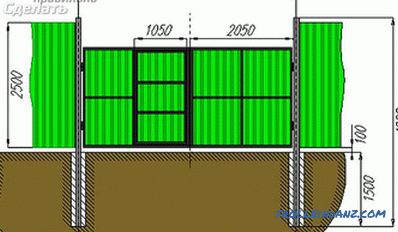

Drawing of sliding gates

Drawing of sliding gates

Gates from different angles

Gates from different angles

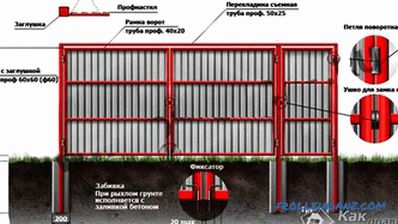

Gate frame

Gate frame

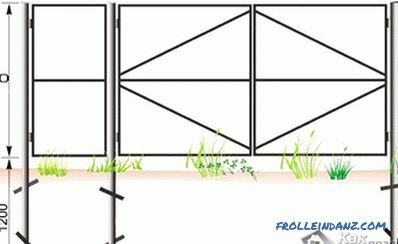

Gate construction

Gate construction

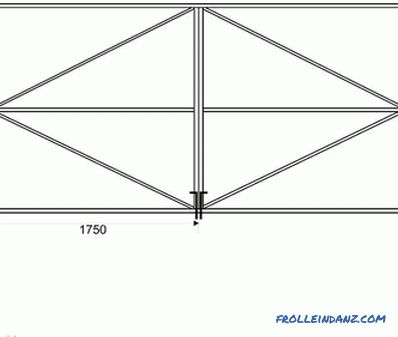

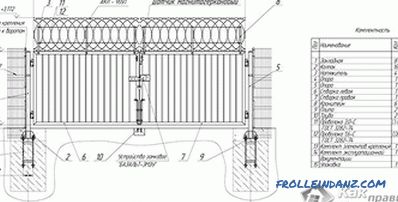

Sliding gate design

Sliding gate design

Kit tion swing gates

Kit tion swing gates