To save money when carrying out repairs in an apartment, you need to perform many types of work yourself. To do this, you need to know, for example, how to make a floor screed with your own hands. Screed is a sexual layer, intended for laying the floor covering. It is on its quality indicators that the future performance of the floor will depend.

Floor screed can be of two types:

- Monolithic (cement-sand, gypsum, self-leveling);

- Dry screed.

Measures before pouring the screed

Using the damper tape

Using the damper tape

- Cement screed is made of cement and sand at a ratio of 3: 1 with the addition of water;

- The type of screed is determined based on the functional purpose of the room and its humidity;

- Next in the room is determined the zero level using water level. The zero point is determined simultaneously in all rooms at a distance of 150 cm from the floor surface. At this distance, a mark is made on the wall and projected onto all other walls using the water level. Then all the marks are connected by a single line, and the zero level of all rooms is obtained;

- Measure the distance from the line to the floor surface on all walls. The smallest figure suggests that at this point the floor is the highest;

- Having decided on the type of screed, proceed to the preparation of the base for its application. You will need to dismantle the flooring, remove the peeling base elements, and then remove dust from the surface with a vacuum cleaner. The final step in the preparation will be the primer base for better setting.

When using all types of screeds, except for self-leveling, the screed layer should exceed 3 cm.

Technological process of filling the floor with a coupler

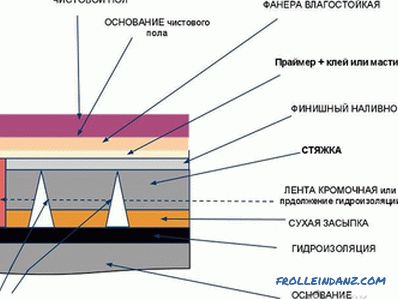

Construction of the screed

Construction of the screed

The bottom of the walls around the perimeter is glued with a ruberoid tape so that its width exceeds the future layer of the screed by 15 cm. If on the floor surface there are holes or slots, process them with a non-shrinking glue that will protect your neighbors from the bottom of the screed.

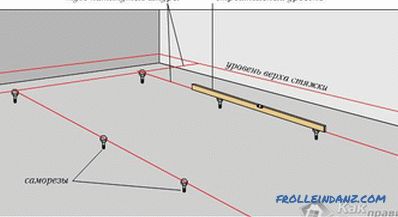

Beacons for pouring

Installing beacons

Installing beacons

A further step to self-fill the screed arrangement of beacons. The course of further work depends on the quality of their installation. The role of lighthouses will play T-shaped guides of metal. They are fixed with a screed solution. The first lighthouse is located at a distance of 20 cm from the surface of the wall. The rest of the lighthouses are attached parallel to each other in increments of 30-40 cm. Having laid the lighthouses on the solution, align them with a level. It is necessary to level in all directions from the lighthouses. If the level on the entire surface of the floor is zero, then you did everything correctly, then it remains to wait for the solution to solidify.

Pouring mortar for screed

Aligning the screed

Aligning the screed

Screed casting technology Once the beacons are installed and the solution is completely frozen, you can start the screed filling directly. This is done as follows: a mixed solution is poured between two beacons, starting from the far wall. Further, using the rule, the layer is leveled towards itself. Similarly, the entire surface of the floor is poured. It is advisable to carry out this process with a partner who will level the layer while you are kneading a new portion of the solution.

Screed casting technology Once the beacons are installed and the solution is completely frozen, you can start the screed filling directly. This is done as follows: a mixed solution is poured between two beacons, starting from the far wall. Further, using the rule, the layer is leveled towards itself. Similarly, the entire surface of the floor is poured. It is advisable to carry out this process with a partner who will level the layer while you are kneading a new portion of the solution.

Final procedures for self-fastening

Final procedures

Final procedures

After all the room is covered with a screed, the process is not over yet. You need to provide optimal conditions for its drying. For complete hardening of the layer will take from 24 to 28 days. To prevent the screed from drying out early, it must be sprayed with water several times a day for at least 14 days. Or you can lay a plastic wrap on the floor and moisten it as it dries.

You can walk on the floor a week later, but the screed will be ready for use only after a month. If you hurry, then all the work done may be spoiled, and you have to start all over again.

Checking the work done

Finishing work

Finishing work

After the required amount time, you need to make sure the quality of the screed.

- Perform a visual inspection of the color of the coating - it should be uniform.

- You need to check the flatness of the surface with the help of the two-meter rule. Norms allowable clearances of no more than 4mm.

- Next, check the surface hardness by hitting a tangential hammer. In case of improper exposure the floor may become cracked.

This process of self-priming the floor screed can be considered finished, and if you have done everything, following the technology, then your floor will serve you the maximum allowable period and will please you and the whole family.

Otherwise, you will have to redo all the work first or seek the help of professionals, and this in turn will require large financial costs.

We recommend reading:

laying laminate on a wooden floor with your own hands.

Video

Detailed instructions for performing floor screed in video format: