Bathroom floor plays one of the most important roles. This is due to the fact that this room is always high humidity. To prevent dampness and moisture from becoming your main enemy, it is important to make the bathroom floor according to all technological requirements. We will take a detailed look at how to make a bathroom floor with your own hands.

How should it be?

We list a number of requirements that apply to the quality of the floor in this room:

- Safety for movement.

- Ecological cleanliness.

- Insulation, which should provide protection from negative noise, heat loss, as well as moisture penetration.

- Beautiful appearance.

- Easy to maintain.

- Durability.

In fact, all these indicators can be really achieved. We can distinguish two components, the observance of which will allow this to be done: the right choice of floor covering and the observance of the technology of its installation. Before we begin the work itself, you should carefully familiarize yourself with the types of flooring that can be put in the bathroom.

Finishing materials

As for the flooring, it should mainly be practical, reliable and suitable for your chosen interior. Today there is a sufficient amount of building materials that can meet all these and the above requirements.

Ceramic floor. Due to its high moisture resistance, it is in high demand. Moreover, the floor, covered with ceramic tiles, will have an attractive appearance. Under the influence of external factors, it will not be deformed. To the surface was not slippery, it is recommended to purchase tiles with a rough surface.

Ceramic tile

Ceramic tile

Self-leveling floor. This floor is one of the most recent and modern developments. The polymer mass is evenly distributed over the floor surface. As for its service life, it can serve for several decades. Bulk floor resistant to moisture and, most importantly, does not slip. It can be perfectly combined with a water heated floor. Staying in the bathroom in this case will be much more comfortable. The main drawback of the self-leveling floor is the high price. But it's worth it!

Bulk

Bulk

Linoleum PVC. This is one of the inexpensive, but high-quality coatings. Linoleum PVC is very easy to lay. For a bathroom it is necessary to choose linoleum on a moisture resistant basis. Like tile, it is recommended to choose linoleum with a rough surface.

Linoleum

Linoleum

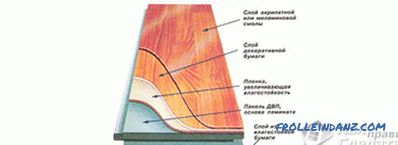

Moisture-resistant laminate. As you know, the laminate will not last for a long time if there will always be water on its surface, therefore, after each bath, all the accumulated moisture from the surface of the laminate must be removed. But it's not a problem. If you properly care for the laminate, it will last a long time. Today, a wide selection of laminates of various colors and shades is produced, so that you can create coziness and comfort in the bathroom.

Waterproof laminate

Waterproof laminate

Carpet. This material is not too waterproof. Despite the fact that there is moisture-resistant carpet, it will be difficult to find it, but for the price it is very expensive.

Natural stone. This finishing material is an excellent tool for finishing the bathroom floor. However, its significant minus is coldness, so walking barefoot on it will be dangerous to health. Moreover, its surface is very slippery.

Tiles made of natural stone

Tiles made of natural stone

Wooden flooring. If you want to make a wooden floor in the bathroom, it will take a long time to process the wood to achieve moisture resistance. As practice shows, this floor is not very practical to use, as well as very expensive.

When choosing a method for finishing the floor in a bathroom, strive to create as few joints and seams as possible. The maximum cast surface will create additional protection against moisture penetration, the appearance of dampness, fungus and mold.

Corking

Corking

Some people prefer cork flooring, although it is significantly inferior to the above coatings. In appearance, the cork floor resembles a “layer cake”. These layers are arranged as follows: the main extruded layer is a cork, the decorative layer is a cork layer, and also a protective layer made of PVC. There are two types of cork. They are completely different in the way they are mounted. The first - has the tongue / groove locking technology. Another type involves laying the cork to a perfectly flat surface.

If a warm floor technology is to be used, the adhesive must be resistant to the effects of heating equipment. Such glue should completely exclude the possibility of expansion due to temperature changes. This condition must be observed regardless of the type of flooring to be laid.

So, now consider the sequence of work performed, ranging from preparation and ending with finishing the floor in the bathroom.

Technological processes

The whole process of making the floor in the bathroom can be divided into several activities. Each stage is important in its own way:

- Preparatory work with a draft floor.

- Waterproofing the bathroom floor.

- Filling the screed.

- Laying finishing material.

Now, more about each stage.

Preparatory work with a draft floor.

Dismantling the old tile

Dismantling the old tile

In most cases in the bathroom The room has an old screed. Therefore, the first step is to clean the surface of the old flooring. It should eliminate all greasy stains, old paint and other possible contaminants that will prevent good performance. Places where the screed fits the wall must be carefully processed. Make sure that the floor is not breathing, so to speak.

If a hollow sound is heard when it is tapped, then you will have to completely remove the draft tie. This is important, because when applying new layers, it can sag. If the base of the floor is reliable, then inspect it for cracks, holes and crevices. If they are, they should be covered with tile adhesive. Do not ignore this process. After all, in such a simple way you can prevent the rapid deterioration of the waterproofing layer. If significant irregularities are found, they are recommended to be fixed with the help of ready leveling compounds. Before the next stage - waterproofing - it is worth treating the floor surface with a primer, which will increase adhesion.

Waterproofing.

Several types of building materials are used to create a waterproofing layer. Each of them differs according to the method of their application to the surface of the floor. Therefore, we now consider their main differences.

Waterproofing with bitumen emulsion

Waterproofing with bitumen emulsion

- pasting material. This type is relevant in those places where there is a need for waterproofing not only the floor, but also some vertical planes. As a result, the treated surface will resemble a bowl with a height of walls up to 150 mm. For its application there is no need to possess any professional skills.

- Bitumen emulsion. It is applied with a roller or brush. It is impossible to call it practical, since the average period of its operation is no more than five years.

- Lubricant. It creates an ideal waterproof surface.

Floor waterproofing

Floor waterproofing

Consider an example of applying a coating waterproofing layer that is more popular. First of all, in places where walls and floors are joined, waterproofing tape is laid. Next, prepare the coating material. By consistency, it will resemble sour cream. The waterproofing mixture should be applied to the surface with a spatula or roller. You can handle and walls to a height of 100 mm. Sometimes you want to apply a certain number of layers, it depends on the manufacturer. You can find out about this in the instructions on the label.

Before proceeding to the next stage of work, you need to wait until the waterproofing layer is completely dry.

How to prepare and apply oblazochnoy waterproofing shown in the video:

If you have a wooden house, floor decks are made of wood, it is recommended to use additional protection or safety layer. To do this, you can buy inexpensive linoleum. It can also be laid on the floor after waterproofing.

Filling the screed.

On the basis of how well this stage of work will be performed, the result of finishing with the finishing material depends.

Filling the screed

Filling the screed

- The first step is to determine the height of the planned screed. For this you need to use measuring devices, for example, a laser level. With it, beat off a flat line around the perimeter of the bath. This procedure can also be performed using the water level. The most important thing is the exact measurements that will allow you to create a flat and durable tie.

- When the level is indicated, you must install beacons or a rail. At the same time, a rope is stretched from wall to wall all over the plane (you can make a zigzag shape). The rope is fastened to the mark of the indicated floor level. As a result, you can set each lighthouse separately. The beacons themselves are recommended to be installed on cement mortar.Until the solution has dried completely, the position of the lighthouse can be slightly corrected.

- Now the prepared solution is poured between beacons. It is important to do it carefully, so as not to damage the previously installed beacon. The whole space is filled with a solution, which after is aligned with the rule strictly according to the beacons.

When all work on the fabrication of the screed is completed, it is necessary to give it enough time to dry completely. Temperature should be natural. If the floor is pre-laid water or electric floor heating, it should be turned off. If you leave it in working condition, the screed will dry out and crack. You will have to completely redo all the work.

When the screed is completely dry, it is time to finish. Consider three options for finishing materials that have differences in installation technology and price - it is linoleum, ceramic tile and self-leveling floor.

Economical option - linoleum!

Laying linoleum

Laying linoleum

For those there is no opportunity to get a tile or to make a bulk floor; there is an excellent option - linoleum. If you laid a warm water or electric floor, then laying insulation is not necessary. Based on the fact that you have already prepared the coupler, you should purchase multi-layer linoleum. Its basis consists of felt and fabric. Linoleum will serve as a heat insulator. The width of the linoleum should be chosen according to the width of the bathroom. This will completely avoid the need to dock the material. It is previously recommended to let linoleum lie on the floor in a rolled state. This will allow it to level. Some believe that it is not necessary to glue linoleum, you can press it with a plinth - it is economical and simple. However, in this case there is a risk of waves. For this reason, the most reliable method of laying linoleum is gluing to mastic or glue. On the concrete screed is best to use mastic. For laying linoleum you need:

- Notched trowel.

- Bitumen mastic.

- Powerful roller.

- Scissors.

Roll the linoleum face down inside. Then both linoleum and the floor should be applied evenly mastic. On average, the thickness can be up to 0.5 mm. When the linoleum is glued, you need to immediately smooth out its surface with a roller. If the bathroom is large, and you can’t get by with just one sheet, you can do a small overlap up to 10 centimeters at the joints. And after complete drying of the mastic, after three days, you can glue the joints. So it turns out to do the job neater and better.

Ceramic tile - a classic of old times!

Ceramic tile was, is and will be the most popular building material for processing bathroom floors. The duration of its service will directly depend on the correct installation. For this reason, now consider some aspects of this process.

Before you start working, unpack the tile and lay it on the floor without glue. So, you can decide in which direction and how best to place a possible pattern.

The tile laying process

The tile laying process

To lay the tile, you need the following set of tools:

- bubble level,

- trowel,

- spatula with teeth,

- mixer,

- capacity for mixing glue,

- plastic crosses,

- rubber trowel.

It is possible that in the process of work you will need another tool. Regarding the process of laying tile, regardless of its size, shape and cost, the laying technology has a common sequence. First of all, it is necessary to determine the direction of the rows, and also decide which side you will start to lay the tile, whether to cut the tile, laying out the first row in order to observe some pattern or symmetry.

As a rule, the tile is put from the far corner and to the exit. It is also extremely important to carry out the correct mixing of glue. After kneading, it is recommended to let it stand for ten minutes. After the solution is re-mixed with a mixer, and the glue is ready for use. As for the application of glue, there are no special rules. It can be applied directly to the tile, it can be applied directly to the floor. It all depends on how you prefer.

In the process of laying tiles, you must use special plastic crosses. With their help, you can achieve absolute equality of the seams between the tiles. As a rule, there are eight crosses on one tile, but they intersect with adjacent tiles. With a slight indentation of the tile, the glue mortar may come out. It should not be allowed to dry out; use a damp cloth to immediately clean the tile.

First, all the whole tiles are laid out. In the corners and along the edges of the "trimming" can be reported after the main array is laid out.Try to calculate so that the cutting elements of the tile are located in an inconspicuous place.

Diagonal tile layout

Diagonal tile layout

When the entire tile is laid, it remains to rub the seams. Pre-recommended to clean the seams by removing residual glue. This should be done carefully so as not to damage the edges of the tile. Grouting is best done with a rubber trowel. This will prevent scratching. When the grout is dry, it remains to just wash its surface well from possible stains.

If there is a floor heating system in the floor, then make sure that it is turned off. Otherwise the glue will dry very quickly and will not hold the tile.

Instructions for laying tiles, see below:

Self-leveling floor - a technological breakthrough!

How prepare the foundation for pouring the self-leveling floor

How prepare the foundation for pouring the self-leveling floor

in recent years, bulk floors have begun to crowd out conventional technologies that we have long loved. Moreover, it should be noted and the fact that they can be made by hand. If all the preliminary processes for leveling the floor were done perfectly well, then you should not experience problems in your work. The filling of self-leveling floors can be divided into several steps:

- First, the surface level of the future self-leveling floor is determined. This can be easily done using a laser level.

- After the mixture of a self-leveling floor is prepared in accordance with all the requirements specified by the manufacturer.

- Filling of the floor should be carried out in stages, and not immediately. Do it from the corner to the door.

- After the mixture should be leveled with a wide spatula. Ideally, it would be to use a squeegee, which is equipped with a special adjustable gap.

- The first layer should polymerize well. For this process, you must allocate two days. The first layer will serve as the base.

- The topcoat should be applied using the same technology as the first coat.

Filling the base layer

Filling the base layer

The leveling floor should dry well and harden. During this process, it releases harmful toxins.

It is in this sequence that the floor is processed according to the method of self-leveling floor.

It all depends on taste.

So, we looked at the main points of how to make the bathroom floor by yourself. To work from beginning to end successfully, you should follow all the recommendations and tips that you could read above. As for the choice of finishing materials, there is a huge selection of building materials. We reviewed with you only the three most common types of finishes. In many ways, everything will depend on you.

If during the work you have difficulties, you can write about it in your comments to this article. And at the same time, if you have enough experience, you can leave your own recommendations for making the floor in the bathroom on your own!

We recommend that you read:

- self-leveling 3d floor with your own hands;

- Do-it-yourself shower stall in the house.