The frame house was designed more than 100 years ago in America and was first used as a quick and mass housing for workers. It is noteworthy that these villages are preserved today. This is a convenient and simple solution. It takes much less time and physical expenses to build a frame house than to build a similar chopped house. Thanks to this, many are interested in how to build a frame house with their own hands and whether it is possible to do it.

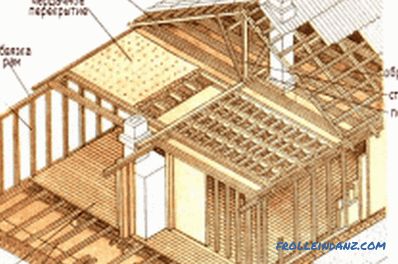

The main feature of the frame buildings is that their walls consist of racks, straps, are insulated and covered with finishing materials.

The main feature of such a house is that its walls are made of pillars, claddings, insulated and covered with finishing material. This allows you to quickly carry out the construction of a frame house, and its service life is at least 30 years. If it is correct to operate such a structure and carry out its processing, then the service life of a frame house is increased by 3 times or more.

Panel-frame houses are popular in the Scandinavian countries.

Despite the fact that the construction of a frame-panel house is 2 times less wood than the construction of the same log house, in its characteristics it is not inferior to him, often the thermal characteristics of a frame house are better than a log house .

The frame-shield house is very popular in the Scandinavian countries, such structures have been installed there for a long time, and they are developing the technology for their construction. Modern frame house has a strong insulation, for this purpose mineral wool is most often used. In order to give such a structure an attractive look, outside it is trimmed with tongue-and-groove plates, it looks almost indistinguishable from a chopped house, and it is quite possible to make a frame house with your own hands.

The design of the frame house

The frame of the specified building is made of supporting struts, which are reinforced with braces and trim. For braces, wooden bars with a section of 50x100 or 100x100 mm are used, they are installed in increments of 0.5-1.5 m and are tied to window and door openings.

The design of the frame house.

The racks of the frame house are installed on the lower straps. For the manufacture of straps use bars or boards, they are based on the base itself or on the beams of the basement floor. Attaching straps is performed with nails, staples or spikes. Depending on the material that will be used to house the house, the racks are mounted at different distances.

In order for the load to be evenly transferred to the walls and the floor, between the beams used for the attic and basement floor, the distance must be the same as between the racks. To make the construction more rigid, it is imperative that plank struts be placed between the uprights on both their sides, the method of their fastening is piercing flush with the trim. After the fastener is made on the top trim, it should be done better on the spikes, the ceiling beams are inserted, the rafters are fastened to them.

In the places where windows and doors will be installed, additional bars are installed between racks, they are used for fastening window and door frames to them.

In order to make the internal partitions of the frame house, install the racks, the fastening of the partition will be carried out using the bottom trim of the house.

Roof construction of a frame house.

For exterior cladding, it is necessary to use materials resistant to atmospheric precipitation, well protecting the room from moisture and cold. Very often, the outer casing of such a house is carried out in two stages: first, fixing the roughing boards, and then installing the facing material. For the decoration of the house can be used finishing materials such as wall paneling, shingles, bricks or other materials that are widely represented in the construction market.

Most often pine or spruce boards are used as a rough finishing material, since it is a fairly durable and reliable material, but at the same time inexpensive. To give the house structure maximum rigidity, they are mounted horizontally.

A variety of ways of joining boards can be used, such as butt, overlap, and tongue, but in order to protect the house as much as possible from the wind, it is recommended to mount the boards with an overlap and tongue. Between the facing material and the boards, special waterproof paper is attached, it serves as an additional protection of the wooden structure against the negative effect of moisture. So that there is ventilation between the rough finish and the outer trim, after installing the rough cladding, the slats are attached to it, and the outer trim is fixed to them. Although this is a more expensive way, you will more reliably protect the wood from destruction, and the house will turn out to be warmer and stronger.

Construction of the foundation and frame

You can use a strip foundation for the construction of a frame house.

A frame house is usually not made above 2 floors, especially if the construction is carried out independently. For such structures to do a deep and very strong foundation is not necessary.

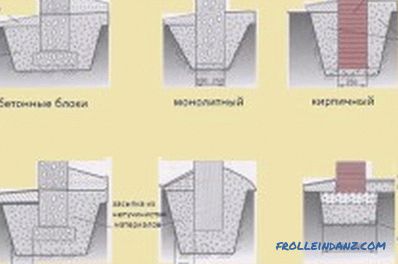

For a frame house, it is best to choose a tape, columnar construction or from ready-made concrete blocks. The main thing is that the foundation is reliable and provide a rigid installation of the frame. To do this, when creating a band construction, it is necessary to use reinforcement; in the columnar foundation, this provides a monolithic grillage. If you make a foundation of blocks, then you need to securely fasten the lower trim.

To make a frame, you can use wood or metal. If you build with your own hands, then the metal frame is almost never used, since its creation is more complex and it is 30-40% more expensive than wooden.

Types of column foundations for a frame house.

To create the framework, it is best to use oak or other hard rocks with a cross section of 150x150 mm. At the corners of the joint, spike into the groove. For joining, it is better to use wooden pins, because when the metal and wood interact, it will rot over time and the mount will weaken.

Many people make a mistake without paying attention to the installation of braces, since without them it is easier to install insulation. But without them, the house will have a weak rigidity, it can twist or fall apart. For braces usually use the same material as for the racks, according to the technology, it is necessary to install 3 braces. Since, at first, wood from the action of external factors will intensively shrink and swell, it is impossible to fix the outer boards rigidly.

Materials and tools for work

The work will require the following tools and materials:

- hammer;

- chisel;

- planer;

- wood saw;

- drill;

- measuring tools;

- ladder.

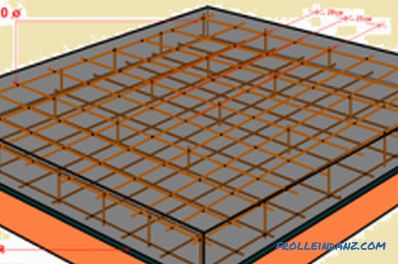

A slab foundation can also be made under a frame house, but it will be much more expensive than other types of foundations.

Materials:

- concrete and reinforcement for the foundation;

- material for waterproofing;

- boards for the frame, internal and load-bearing walls;

- sheets OSB or chipboard;

- insulation;

- facing materials;

- roof material;

- materials for laying the power grid , plumbing, sewage and other communications.

Arrangement of the floor and walls, insulation of the house

In order to lay the floor, first a timber with a section of 150x50 mm is laid along the perimeter of the walls of the house. Before this, it is necessary to put roofing material or other waterproofing material and cover the wood with an antiseptic solution. Anchor bolts are used to fix the timber, they can be installed after 2 m.

Since different types of wood have different coefficients of expansion, it is necessary to use the same wood to create a frame for the walls and the floor. For a subfloor, to save money, you can use an unedged board. After the logs are installed, the insulation is laid and boards are laid.

"Pie" of the warming of a frame house.

Before you install the walls of a frame house, they need to be assembled, this requires that there is a flat and dry platform. The height of the walls of the house must be at least 2.4 m, otherwise you will feel uncomfortable in such a room, the situation will be oppressive.

If the house is two-storeyed, then on the second floor you can make slanting ceilings, so you can save construction material. The width of the wallboards should correspond to the size of the material that will be used for their decoration.

If the walls are to be sheathed with siding, then the distance between the beams should be no more than 30 cm, since it cannot bear heavy loads. If a block house or a chipboard is used, the distance can be up to 60 cm, since this is a more durable material. It is often used exactly siding, because it does not require additional processing, has a low cost, but its disadvantage is that it is not natural wood.

If such a house is made in an industrial environment, then sandwich panels are used for the manufacture of walls, they have a low weight, so the load on the foundation is minimal, moreover, the building’s insulation is not required, since such panels have a low thermal conductivity.

When deciding on the insulation of a house, it is necessary to proceed from its purpose - it will be used as temporary or permanent housing.

If you live in the house permanently, then you should take care of its good thermal insulation, for this there are a lot of thermal insulation materials. For example, 4 cm of foam replaces a board 140 mm wide, 380 mm of reinforced concrete or 860 mm of brick.

Installation of windows and a roof

Windows occupy a fairly large area of the house, on average, about 18% of the load-bearing walls, so great attention should be paid to their installation.

If the house will live only during the warm season, then it is enough to install single-glazed windows, if all year-round, then double or triple glazing should be installed.

In order to install windows, you first need to insert a window block. Then, using wooden wedges, expose the window and fasten it; this can be done using self-tapping screws. The space between the window and the wall is filled with foam. At this time, the window should be closed. If there is no protective film on the window, then it should be covered with masking tape, this is required in order not to damage during installation and not to smear it with mounting foam.

Installation of exterior doors and windows is carried out before the communications are installed in the house and its interior is made, the interior doors are installed after the walls are finished and the flooring has been laid.

There are also many materials for roof covering: metal tile, soft roofing, profiled sheets.

The main enemy of such a house is humidity, therefore it is necessary to correctly determine the place for the construction of a frame house so that there is no need to make a drainage system for removing surface and groundwater. You can not build a house near large trees, since the moisture from them will constantly fall on the house, and the roots will begin to destroy the foundation.

If you follow these recommendations, have the necessary set of tools, materials and basic construction skills, you can build such a house with your own hands. Everything can be done quickly, but despite this, the design is strong, reliable, warm and durable.