It is no exaggeration to say that the internal flooring is the most used surface in the house. Most of their time on it is spent by children and animals. To prevent diseases, in particular the cold, you need to think about how to warm the old floor in a private house. In addition, it will also help reduce heating costs.

What to consider before

Determine the initial conditions

Determine the initial conditions

Cold air always accumulates from below , and warm rises, therefore, how many do not top the house, if the floor remains cold, then it is almost impossible to achieve full comfort. Before doing installation work, it is necessary to analyze a few points:

- What the flooring is made of. This may be a concrete screed on which the tile is laid, perhaps this is a trim board.

- If the floor is wooden, is there any pests in it?

- Whether there is mold in the corners that spreads from the bottom up.

- Does moisture accumulate under the coating?

- Is there any space under the floor?

- Will it be critical if you even have to raise the level a little?

- Is there a basement downstairs? If not, which floor is located under the floor.

- Does he bend while walking?

There may be a concrete screed under the floor

There may be a concrete screed under the floor

From what will be the answers to these questions , it will depend on whether the old coating can be used or whether it must be dismantled with the need for additional measures for decontamination and insulation.

Choice of a way of warming

Until now, a large number of varieties of material have been developed for warming. To apply them best in specific conditions, it is important to get to know their weak and strong points.

You can use expanded clay

You can use expanded clay

as a heater. One of the methods of insulation that has been used for a long time and does not lose its popularity, is the use of expanded clay. It is made from natural components, and the manufacturing process consists in burning the basis of clay. This material wins by the following parameters:

- low weight;

- choice of granule size;

- relatively low price;

- moisture resistance ( does not collapse under its influence);

- long service life;

- resistance to temperature drops;

- resistance to fire.

Among the shortcomings we can highlight:

- in some cases it is necessary to make an indentation to provide a sufficient layer;

- fragility;

- to draw in moisture, which leads to its accumulation in the granules.

Polyfoam

Polyfoam

The next item in the list of materials that can be used for insulation purposes is Styrofoam. Its strengths include:

- a high level of thermal insulation (with the same thickness compared to other materials, except for foam plastic, it will always exceed in performance);

- low weight;

- ease of fitting and styling;

- inedible for parasites (although mice and rats do an excellent job with it);

- do not absorb moisture;

- resistant to high temperatures ( without direct exposure);

- no thermal expansion.

If you choose foam, you need to consider:

- unwanted use with a wooden coating due to fire hazard;

- chemical instability and physical impact;

- toxic when burning;

- when insulating with foam plastic it is important to correctly calculate everything so that the dew point does not remain under the floor.

Mineral wool

Mineral wool

Many people often have a choice between this material and mineral wool. For its manufacture can use the battle of glass, quartz, rock or slag. If we talk about the positive qualities, it is:

- excellent sound and heat insulation;

- resistance to fire (especially in stone wool);

- resistance to chemical attack ;

- good vapor permeability;

- high tensile strength (for some brands);

Of the sad moments, the following can be noted:

- inconvenience of mounting glass wool (it is necessary to use clothes that will prevent it from getting on the body, as well as glasses, gloves and a respirator);

- possibility of compaction over time, which leads to the appearance of mos ticks of cold;

- unpleasant dust;

- some types of this material absorb moisture well.

Polyfoam

Polyfoam

Polyfoam is very similar in its characteristics to the foam. It has even greater thermal insulation. It can be applied in any weather conditions. We also like rodents and are afraid of high temperature (with direct exposure). In some cases, the insulation can be made using gypsum fiber.It is used in conjunction with a dry screed. As a method, you can consider filling the cavities with foamed polyurethane. Under certain conditions, this can be done without removing the old floor.

Vermiculite

Vermiculite

Vermiculite is a fine, durable material, resistant to moisture, but its cost is quite high therefore, not everyone will afford to purchase it for floor insulation.

The ideal solution would be to combine passive insulation with an active warm floor. For the latter, a large number of species are available today, which include water and electric versions.

Planning

Tree preservative

Tree preservative

In addition to calculating the amount of the main material and necessary work, the questions at the beginning helped to determine whether additional components would be needed:

- If mold or fungus grows, it will be necessary to additionally purchase an antiseptic composition.

- When detecting a dingy, the best option would be to replace the boards, since there is no one hundred percent guarantee that you will remove it, and it will be very unpleasant to disassemble the entire floor after all the work is completed.

- If there is creaking and sagging, you will need to assess well the state of the lag. May require replacement. For this you have to purchase additional lumber. Final determination of their actual condition is possible only after dismantling the top layer of the facing material.

-

Waterproofing In case of proximity of groundwater or another reason for a large accumulation of moisture, it is important to purchase waterproofing, in some cases it is better to have several layers.

Waterproofing In case of proximity of groundwater or another reason for a large accumulation of moisture, it is important to purchase waterproofing, in some cases it is better to have several layers. - For quality insulation, excavation at a certain depth is required. Either it will be necessary to simply replace sand or expanded clay, which has already exhausted its service life (it usually ranges from 10 to 15 years). To accomplish this, garbage bags are required.

- If you are planning to install a heated floor, then it will be necessary to purchase components depending on which option you have chosen. For water, you will need a metal-plastic or cross-linked polyethylene pipe, manifolds, stop valves, and fixing materials. For electric you can buy ready-made mats.

- For the tie, reinforcement and knitting wire are required.

To purchase the right amount of material, you first need to calculate the area of the room. For this, the length is multiplied by the width. The resulting number will be our foundation. For insulation thickness of the beams can be neglected, because all the same, it must be taken with a small margin. The area of hydro- and vapor barrier will also be equal to the area, an overlap will need to be added to the final value, which should be 10–15 cm.

Work performance

Warming by polyurethane foam

Warming by polyurethane foam

In that case you are sure that the state of the underground space is close to good. For example, under a wooden base there is a concrete screed, which can serve for many years, and the logs themselves lie on a cement base, then the work can be carried out without large-scale dismantling.

- All furniture is taken out of the room and thorough cleaning is done.

- Places that need to be protected are covered with construction tape.

- One board is removed between each of the lags.

- The space is filled with foamed polyurethane. It is necessary to move the hose so that all voids are filled.

- Additional hydro- or vapor barrier is not required, since after solidification the base will perform all these functions.

- When the foam has taken its shape and is completely dry, the boards are mounted back.

Filling the underfloor with ecowool

Filling the underfloor with ecowool

Another option with a good base under by flooring - disrupt all boards, cover the entire area with a vapor barrier and lay insulation in the niches above. If the wooden flooring is in perfect condition and it is possible to raise the floor by 10 cm, then you can use the dry screed method. To implement it, the entire area is covered with a vapor barrier. The crate is made of wooden beams, expanded clay or other filler is poured into the space. The foundation for the finishing floor is laid on top and the final finish is performed.

In all other cases, which will be described below, the first two steps are repeated, after which you will need to remove the entire flooring. If you have a dry floor under your floor, then the following scenarios can be developed:

- Sand that could have turned to stone in time must be removed. This will require construction bags. They are filled and taken out of the house.

- When you know for sure that the groundwater does not come close, and you do not plan to fill the screed, the foundation, which was under the sand, is well tamped.

- The surface is covered with a membrane or thick polyethylene film. Separate parts are laid with an overlap of 50 cm. The seams are glued with scotch tape. It is necessary to provide turns on the walls that will reach the level of the future floor.

- The formed space is filled with expanded clay up to the lag, it is well leveled and compacted into all cavities.

- A vapor barrier is attached to the logs so that there are recesses between the boards.

- In between the lags fit insulation. In this case, basalt wool is perfect.

- From above, the whole space is again tightened with a vapor barrier. It is necessary to do this so that the particles of the insulation fiber do not scatter with time.

- The basis from plywood or OSB of a plate keeps within.

- The finishing floor is covered.

Insulation

Insulation

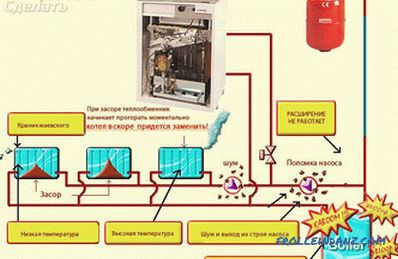

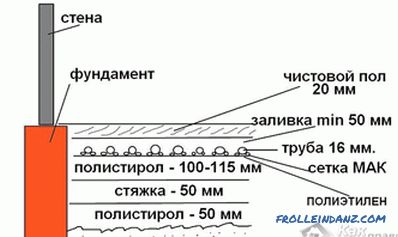

is placed between the lags. If you plan to make a warm floor, then (this option from step 8 is also suitable when there is a concrete base under the floor):

- A recess is made for the size of the future screed plus insulation.

- The base is well rammed and leveled.

- The territory is covered with a hydrobarrier, as in the previous case (in this case, bikrost or roofing felt can be used).

- A crate is made of reinforcement with a diameter of 8 mm. It is laid on the prepared surface.

- Next is pouring concrete. At this stage, it is advisable to try to bring everything under the level so that this will work out, you must first mount the beacons.

- It is compacted with a vibrator so that the concrete fills all the gaps.

- After 3-4 weeks, when the plate becomes a monolith, you can proceed.

- A hydro-barrier is covered, a heater is laid on it. You can use foam or foam plastics. It is fastened through to the concrete.

- Grille or pipe guides are mounted, pipes are laid. If this is an electrical option, then mats are placed on the insulation.

- A finishing screed is poured in and after 3 weeks it can be tiled.

Floor heating scheme in a private house

Floor heating scheme in a private house

When you take out the primer , and, perhaps, you will see the need to strengthen the foundation. In this case, formwork is mounted around the perimeter. The width between the shields should be 30‒40 cm. A metal crate is placed inside and filled with mortar. Further work can be continued after the full setting and dismantling of the support system.

If you happen to be the owner of the basement under the house, then the task is much simpler.

- The first thing to do is to go down to the basement. First, the condition of the ceiling is evaluated.

- All slots are covered with plaster.

- Next, the slab is sheathed with foam or foam plaster. Fastening is carried out by special umbrellas. The sheet is applied through it, a hole is made in the punch, and the mounting material is inserted.

- An adhesive is applied on top. Reinforcing mesh can not be used, because no one will beat elbows or knees here.

- From the side of the room the floor is insulated in one of the ways listed above.

In some old houses a concrete screed is poured and linoleum is laid on it. If in this case there is an opportunity to raise the floor, then the cover is simply removed, lags are installed, a hydraulic barrier is laid, then insulation, everything is sewn on top with sheet material, and finishing is a matter of taste of the owner.

As you can see, floor warming can be done by hand. This requires careful consideration of the case. It is impossible to consider all the options within one article, so you are free to combine methods or, based on principles, to do something different.

Video

Thus, as in this clip, you can insulate the floor below:

You can see how to warm the floor in the attic with sawdust, below: