Installing the rafters is an important stage in the construction of the roof. To ensure good stability of the roof, its strength should be properly installed design. From the truss structure will depend on many parameters of the house, which include its protection from weather conditions.

The rafter system performs a carrier function and is an essential element of a stable and durable roof.

Determining the pitch between the elements

When creating the design of the truss system itself, determining the pitch, that is, the distance between the rafters , is very important. It is necessary to determine the optimal distance so that the load on the rafters is evenly distributed and not too large. It should be noted that in addition to its own weight and the weight of the roof, weather conditions (for example, wind or precipitation) will affect the roof. The whole burden of the work will be exactly on the rafters.

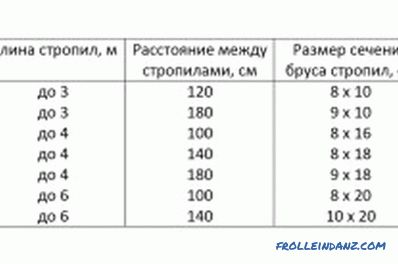

Table of rafters pitch

Based on the above, select the desired distance. But it should be remembered that the minimum distance between the rafters is 60 cm, and the maximum value can be greater than 1 m. In addition, there is a definition of a suitable step based on parameters such as the length of the rafters and the size of the bar section. Data is presented in tabular form.

To determine the required number of rafters for one side of the roof slope, the length of the ramp itself should be divided by the required rafters step presented in the table. The resulting value is added 1, then the figure is rounded to a whole number. The end result is the amount of rafters for one side of the roof. Next, you can determine the center distance between the elements of the truss system. To do this, the length of the slope should be divided by the result obtained during the first calculation.

Nevertheless, the calculations for this table were carried out without reliance on such moments as the type of insulation, the specificity of the roofing. If heat insulation is required, the distance between the truss system elements should be customized. In addition, the insulation width should be about 2 cm longer than the span between the rafters. A similar problem concerns the choice of material for the roof, therefore the necessary measurements for the distance between the rafters should be carried out taking into account this factor as well.

Preparation for work

All wooden elements of the roof system are made of coniferous trees, the humidity of which does not exceed 20%.

To properly install the rafters, certain knowledge is required. In addition, proper preparation of the material for installation will be required, and the material itself must be of good quality, without cracks or other damage. It is recommended to use conifers, which should be well dried. This eliminates the risk of material deformation. As rafters use a bar or edged boards, you should select the desired section even during the design of the truss system.

All elements made of wood must be treated with bio- and flame retardant agents. Before installing itself, you need to select the appropriate type of mounting. In accordance with the action plan, the necessary materials and equipment are selected:

- Ax.

- Hacksaw.

- Wooden or metal plates.

- Screws, nails, staples.

- Studs with washers and nuts, bolts.

- Boards and beams.

- Wire.

Terminology and some tips

Basic elements of the truss system.

The installation of rafters involves the installation of many elements that have their own name. These concepts are common, and inexperienced or poorly educated people fall into a stupor because of this. Therefore, it is necessary to understand what a word represents.

The main element is the mauerlat. This is a wooden beam, having a section of 15x15 cm. Its main task is to be the bottom support and distribute the load over the entire area of the wall from the joints of the rafters. This element should be mounted a little way away from the wall. To prevent corrosion, it is necessary to isolate the beam from the bottom using roofing felt. The installation of the system starts from the mauerlat.

Another device, necessary to reduce the load, is called lying. The lie is located inside the structures, which distinguishes it from the first element. At the same time, it is not mandatory, but only complements the system when it is required to distribute the load from the rafters.

A rack designed to reinforce the construction of the rafters from the inside is vertical. On it are installed the runs, which are propped up with the help of beams, which are in an inclined position. They are called struts and help to support the previously indicated elements, at the same time prevent the compression of the structure. The run is located horizontally along the entire length of the roof, crossing the rafters perpendicularly.In addition, a bolt is used to give strength. This element is a beam, which is set feet rafters.

Features of installation of different types of structures

For the purpose of building the roof, truss structures of 2 types are used - hung and hanging.

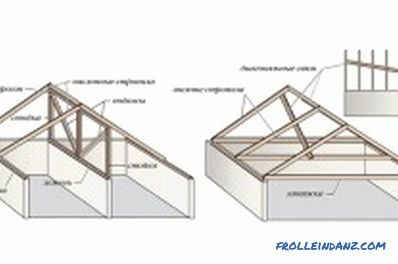

Schematic representation of two types of rafters.

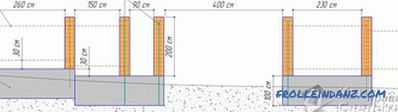

You can use both types at once, if the situation requires. They differ in the method of installation and location: the slats should be mounted using an additional support. This implies the use of this type in the presence of supporting elements (eg, pillars) inside the building or the middle load-bearing wall. The hanging rafters rest on the walls themselves. The diagram shows the types of structures.

In addition, this type can be installed either with or without a power plate, on thin walls. The support will be the ceiling beam, which protrudes from both sides of the building beyond the wall. Rafters are connected with a jumper - bolt or tightening. To block more runs, additional elements are applied. This is necessary for the desired rigidity of the structure itself. If the installation is carried out on a power plate, then the overlap beam may be a puff located low.

Suspended elements are mounted on the power plate. Actually, they rest on the lower ends of it. It is worth noting that the walls must be of sufficient width in order to carry out the installation in which the supporting structure in the form of a bar is used. The bar has a section of 150x150 mm. The top should rest on the ridge girder. It will be necessary to install the girder, for which it is necessary to install the stands on the pillars or the wall in the middle.

Installation design

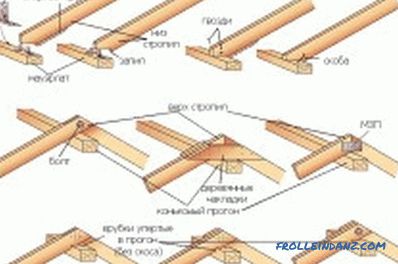

Schematic representation of the rafters mounting options.

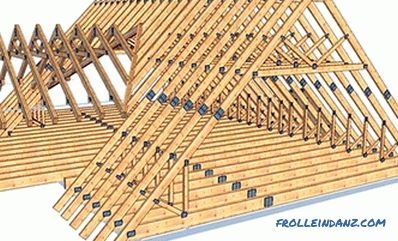

The first step is to make the construction of farms. It can be assembled both on the roof itself (if its weight is large) and on the ground (if the weight is small and there is an opportunity to lift the structure up).

The elements of the trusses are connected by metal plates that have teeth. The plates are pressed into the truss using a press. Next, the remaining elements are collected, resulting in a ready-made truss, necessary for further installation of rafters.

Bottom ends are mounted on rails or beams. After this, the installation of farms occurs, you must first install the extreme farms. To attach the rafters to the beams at the top of the structure, it is necessary to make 2-3 holes in the tie.

You can connect the upper ends of the elements using various methods. The first method of connection - butt rafter attachment. To do this, on the opposite legs you need to make notches, this work is carried out at the right angle. The rafters are joined by the made ends, after which the nails are fastened. The joint must be reinforced with a metal or wood lining.

In addition, foot rafter attachment is used. The structural elements are in contact with each other by planes, for fastening use bolts or studs that have nuts and wide washers.

If the truss system is installed on a wooden house that has gables of logs or lumber, then the structural elements are installed on the walls using a so-called sliding fastener. This will avoid damage to the roof, which can occur during shrinkage of the structure. As for the ridge part of the structure, the feet of the rafters should be positioned so that there is a gap. After this, the elements are fastened; in this case, a special-purpose connecting metal element will be required. Its main feature is mobility.

Thus, it would not be difficult to install rafters according to all construction rules. For construction it is necessary to take the necessary material and equipment, make a good plan for the future roof. Since the installation of rafters is associated with work at height, it is necessary to take the necessary safety measures.

Didn't find the answer in the article? More information on the topic:

-

Technology of laying lining inside the house

Laying lining: preparatory work, the manufacture of frame construction, fixing the insulator and vapor barrier. Installation of lining in different ways to the surface of the frame, painting the lining.