More and more people prefer to build their houses in antiquity. But the very first material used in construction has always been wood. But if before a wooden house was the norm for an ordinary person, and some grandee lived in a castle, now it is a privilege, on the contrary, only wealthy people.

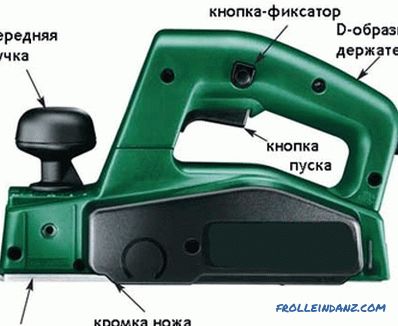

Layout of the device.

Although for the sake of justice it is still worth noting that now there is also enough wood, and if you try very hard, you can build a hut out of more affordable species. Enough to know how to chop a log cabin with your own hands. At the same time, the technology of construction has changed somewhat. At a minimum, wood is now being processed before starting to design a house.

Of course, it is quite expensive to cut a log house, but the most common tools are used. The process itself also requires sufficient time, and in order to somehow save it, it is better to purchase an already dried blockhouse.

What do you get with such a device?

Of course, any wooden building has its positive and negative sides.

Pros:

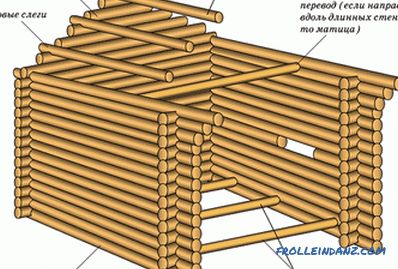

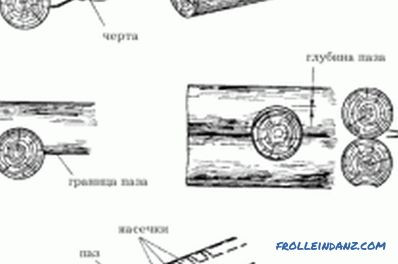

Schema for preparing logs for building a log house.

- The building has a non-standard image.

- The tree does not emit harmful substances, which means it does not harm the health of people inside and the environment.

- The frame has a high thermal insulation property.

- Modern wood is treated with special solutions that do not allow it to damp, which means it can absorb moisture. This treatment helps to prevent the appearance of dampness in the premises.

- Wood is so soft and malleable that it is not difficult to carry out internal work.

- A wooden bar has a light weight, which allows not to waste finances and efforts to build serious foundations. Their load-bearing load is so small that it is possible to use a columnar foundation made of pipes or even do without it.

- To work with a log house, there is enough elementary building tools - a saw, an ax and a chisel.

Cons:

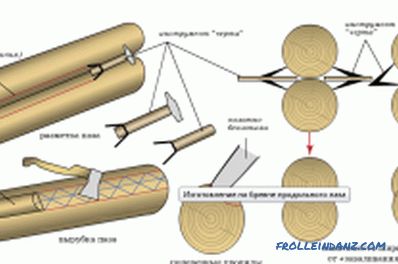

Tools for making a log house.

- First of all, wood is a fire hazardous material. Therefore, in this regard, it is required to handle it very carefully.

- Now wood as a natural material is far from cheap. Therefore, the construction of the house of the log house requires significant financial investments.

- If we compare the "natural" houses and brick, the first lose in terms of operation. Depending on the type and method of processing a log house, it can vary from 50 to 90 years.

- Working with wood still requires knowledge from the basics of carpentry.

- Due to some technological features there is no possibility to implement additional extensions.

- If the tree is not treated in advance with special mixtures and solutions, then insects will be very indifferent to this material.

- The average time for a log house to dry out is 1 year, due to which a building may be deformed. In order to avoid this process to the maximum, the tree needs to be trimmed properly, as well as timely repair.

- If you are engaged in building a dwelling from a log house, you cannot do without helpers.

There are several methods for cutting log houses, and each of them has its own characteristics, positive and negative sides.

How to cut a blockhouse into a paw: features

The scheme of cutting a blockhouse into a paw.

With this technology, the material is very economical, since the entire length of the log is used during the cutting. It is easy enough to make "grooves" in the uneven bars. But you should know that, choosing such a method, it will be necessary to additionally insulate the corners. Some experts believe that such a building will be less stable and not look so impressive.

A frame in the paw has a clean angle, without any projections. A very important point is that the entire timber to be used for construction, had the same thickness. And I would like to note that the thicker the timber, the warmer the house, as in this case there will be less connections.

Construction tools:

- plane or grinder;

- level;

- ax.

So, what are the processing steps in this version:

Preparation. Any timber will have an inner side that is designed for the wrong side of the building, and it should be smooth. This can be achieved with a planer and / or a grinding machine. The edges are also processed in the same way (the distance is equal to half the diameter of the log).

Construction. On the working area two logs are laid parallel to each other, after which the next pair is laid on top of them perpendicularly. It should turn out to be a flat square, the evenness of the corners is controlled with the help of a level, and then it is necessary to mark the timber at both ends.It should be remembered that you need to comply with the nest of planting a log - it should not be more than half the thickness of it. The resulting recess is intended for subsequent logs, which should "paw" lie flat, which just contributes to a good fit.

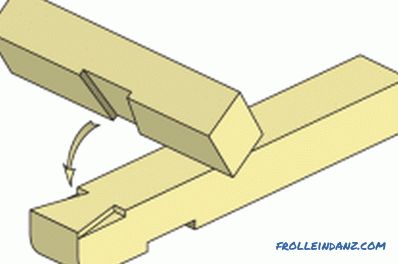

Dovetail Connection Diagram.

For beginners, it often happens that the "paws" have gaps that the ax will not fix. This trouble can be fixed with wooden wedges, but such corrections should not be abused.

There are several ways to fasten the bars between them:

With a stake. To do this, a through hole with a diameter of 3-4 cm is drilled in the "paw" of the upper log, and a stake with a slightly larger diameter is driven in. Such fastening is done in staggered order so that the pegs do not tamper with each other.

A more complex method, but it is considered more reliable.

For this purpose, during the marking and preparation, a thorn sized one quarter of the working surface of the "paw" remains. They need to be stacked on top of each other, like "Lego", and in each log there should be a hole for a spike, which should be located from the inside corner. To avoid any gaps or crevices, use tow or other insulation.

The final moment is the processing of the log, after it is expelled. The tree is covered with solutions that help it not to rot and protect against harmful insects, as well as increase fire resistance.

Corner insulation is also required, and if it is external, then a thorough covering is applied, and if internal insulation is applied.

How to chop up with a “dovetail”?

Cutting scheme “into the bowl”.

This method is similar to the previous one. Dovetail can eliminate all the shortcomings of the paw. This method has a more reliable reinforcement, which eliminates the thorns and stakes. Since the paws are built at a certain angle, this way provides additional protection from the winds.

But it should be noted that it will be extremely difficult for a newcomer to cope with this method, since it is difficult to manufacture the slope of the beam. This design protects the log from moisture during rainy weather.

The method of chopping a log in a “dovetail” is not much different from a “paw”.

You should know that at the very beginning and at the end, the corners should be upholstered with additional waterproofing materials. Moisture on the wood leads to the fact that after drying it loses its original shape.

How to chop a blockhouse "in a bowl": recommendations

This is the very first technique that people have long used. There are fixtures of log cabins, which ensure the stability of the building and good natural insulation. This type of logging helps to save on finishing work.

Of course, such a blockhouse "requires a lot of effort and more resources, which entails more financial costs.

In this version of the work, when building the edges of the logs, they will protrude significantly (by about 20-30 cm), and they are connected by creating special recesses - "cups". It should be immediately noted that due to the fact that there is such a large overhang, the effective area ratio is significantly reduced. But the strength allows you to build not a single-story building.

Tool:

- construction tool "dash";

- saw;

- ax;

- chisel.

So, the stages of work:

Preparation. "Traits" carry out the markup, which is done on the principle of compasses. According to the rules of construction, the “bowl” is always placed at the bottom of the log, thus avoiding unnecessary accumulation of moisture. In depth it is cut so that it is not more than half the diameter of the bar.

After that, the logs are stacked on top of each other, with each bowl exactly matching the bottom log. In order to avoid gaps, you can use a special paste, which quickly freezes, and then creates a good insulating barrier.

As a result, there should be a hut, somewhat similar to the hut of Baba Yaga, and the design will be so strong that it is not required to be strengthened with spikes or stakes.

Finishing work. And again, an autopsy is performed with solutions designed to protect against fires, insects and moisture absorption.

What material is suitable for felling logs?

Once you have decided how to cut a log house, you must decide on the type of wood itself. Basically preference is given to coniferous trees. In order to make the task easier for you, you can work with rounded logs.

They have a fairly symmetrical appearance and the same radius, which greatly simplifies the task of cutting “paws” or “cups”. The notches will be easily the same size. But such material is quite expensive.

A profiled bar can also be used.With this material, the seams and joints will be very tight to each other, as a special conveyor processing creates an accurate thorn-groove system. But despite the good speed of work with such a tree, it is not possible to experiment with it, you will have to act on a template.

Finally, I would like to say that if you take on such work for the first time, it would be nice to do everything under the clear guidance of a professional.