Have you conceived to build a cottage, to build a country house or a bathhouse, to pave paths on a section of paving slabs, or to simply repair a large area? You can not do without large volumes of concrete, and hence without a concrete mixer.

Before you choose a concrete mixer for home and garden, try to figure out how some models are fundamentally different from others, what the possibilities and limitations of each type. Knowing what equipment characteristics you should pay attention to first and foremost, you can prevent mistakes and find exactly what is required to solve your problems.

The principle of operation and the design of the concrete mixer

The concrete mixer is intended for the preparation of cement mortar in a building site. It would seem at first glance, it is easier to buy ready-made concrete, but there are also their own "buts" here. First, considering the difference in the cost of the finished concrete solution and its components, you will understand that with a large amount of work, the new concrete mixer will pay for itself very soon. Secondly, the preparation of the solution on its own allows you to adjust its amount in accordance with changes in current plans.

It should be borne in mind that the concrete solution must be mixed all the time, otherwise it will quickly set. If you were unable to correctly estimate the amount of work that the team of your workers will be able to complete as soon as possible, or for some reason your plans were violated, it turns out that the money spent on the purchase of concrete will be thrown to the wind (moreover, you still have to pay for its disposal).

There are many types of concrete mixers, but all of them have three main structural elements:

Working capacity , called the "drum "or" pear. In it, during the rotation itself, the components of the concrete mortar are mixed. To improve the quality of mixing concrete, blades are located inside the tank, which, depending on the type of concrete mixer, can either be fixed rigidly on the walls of a rotating drum, or, having their own drive, rotate inside a fixed container. The volume of "pears" can vary from a few dozen to several hundred liters.

The power unit , consisting of the engine and transmission, converts the energy into rotational motion necessary for mixing the contents of the working tank.

The bed is a construction made from metal pipes and / or profiles, which holds the working capacity and the power block. If this frame is equipped with wheels, then the mixer becomes mobile.

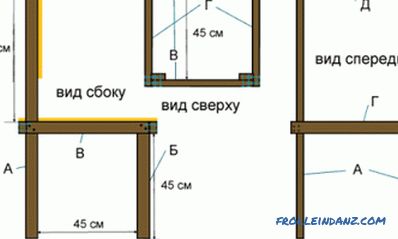

1 . Top of the pear.

2 . Blades.

3 . Bottom of the pear.

4 . Gear crown.

5 . Corkscrew ring.

6 . Corkscrew ring bearing.

7 . Bearing.

8 . Corkscrew ring bearing.

9 . Bearing.

10 . Cradle.

11 . Anther.

12 . Frame.

13 . Control disk.

14 . Spring.

15 . A circle.

16 . Running board

17 . Footboard for wheels.

18 . Wheels.

19 . Cork for the wheels.

20 . Engine.

21 . Corkscrew.

22 . Gear.

Difference between forced and gravity type concrete mixers, their advantages and disadvantages

According to the method of mixing, all concrete mixers can be divided into two groups - with gravity mixing and with forced mixing.

Gravitational type

Mixers of this type you, for sure, had to see - they are widespread much wider than forced ones. As it is easy to guess, the principle of their action is based on gravity. Mixing takes place in a drum rotating around its axis, and this axis is located not vertically, but at a certain angle (sometimes completely horizontal). The components of the future mixture, reaching a peak, under the action of gravity fall down, due to which they are mixed. Such concrete mixers are cheaper and easier to operate than forced ones, but their mixing quality is somewhat lower.

Forced type

In concrete mixers with forced agitation, the working capacity remains stationary during the operation of the apparatus - the blades located in it rotate. This method of mixing is much more efficient, with the result that the mixture quickly achieves a uniform consistency. However, they are not without flaws: firstly, the high price, secondly, more complex, and therefore more expensive repairs in the event of a breakdown, and it is easier to disable them than gravitational ones, because they are intended only to work with small fractional components.

What type of transmission is best crown or gear

The transfer of torque from the engine rotor to the working capacity, in gravity mixers, can also be implemented in different ways. Here emit gear and whip cement mixers.

Gear type

In such concrete mixers, the gearbox is located in a separate housing. It is quite reliable and, importantly, quiet aggregates. It is clear that they are expensive. In addition, in the event of a breakdown, it is necessary to change the entire gear unit, and often the engine, which is almost equivalent to buying a new concrete mixer. In general, they require more careful operation.

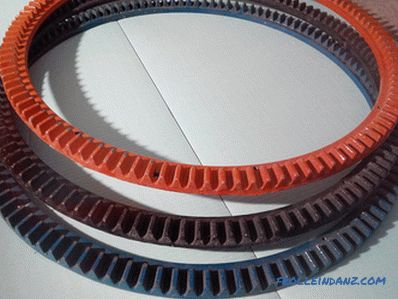

Crown type

More popular among concrete workers who have a cog wheel around the circumference of the working capacity. In the process, the teeth of the crown cling to the drive gear, so that the rotational movement is transmitted from the engine to the drum. Crown cement mixers are much cheaper than gearboxes. Of course, the crown is often out of position, but its replacement is only 1-2 hours of work and 1-2 thousand rubles for spare parts, which is incomparable with the replacement of the gear unit and / or the entire engine.

Negative factors such as friction, greatly increased by contact with cement, sand and other abrasive contaminants, prolonged exposure to precipitation, contribute to the crown wear. , random blows, etc. In order not to have to change the crown too often, you must not only be careful with the technique, but also be knowledgeable about the process of selecting the material of the part.

The crown can be made of the following materials:

- Cast iron.

- Steel.

- Plastic.

- Polyamide.

If the concrete mixer is purchased for private construction with a small amount of work during the day, models with a cast-iron or plastic crown will do. Pig-iron crowns are fragile and, moreover, during work they thunder. Plastic work silently, but quickly wear out. However, with a bunch of flaws, both those and others have one indisputable advantage - low cost. If we are talking about more extensive construction, then concrete mixers with cast-iron or plastic rims will not work - steel is required.

Steel crowns work relatively quietly, but their main advantage lies not in this, but in their durability, which is very important in the conditions of daily hours-long operation. Relatively recently, polyamide crowns appeared on the market, quickly gaining popularity among professionals. Having all the advantages of plastic (low weight, quiet operation, non-susceptibility to corrosion), they also have a very high wear resistance.

How to determine the power unit

According to the type of drive, concrete mixers are divided into mechanical (manual), electric and equipped with an internal combustion engine.

Electric Concrete Mixers

This type of concrete mixer is the most common.

Such mixers are convenient and unpretentious, all that is required for their work is access to the power grid with a voltage of 220 V (for small "household" units) or 380 V (for high-capacity concrete mixers of high productivity).

Concrete mixers with a motor-drive

Concrete mixers powered by an internal combustion engine are not popular for a number of reasons among builders and finishers. The main disadvantages of them include the noise of work and the presence of exhaust, i.e., such units are intended only for work in the open air. In addition, internal combustion engines, as a rule, require more attention than electric motors. However, motorized concrete mixers are indispensable in cases where the object under construction is located at a considerable distance from the power line, and the installation of its own electric generator is for some reason impossible or impractical.

With a manual drive

Like concrete mixers equipped with an internal combustion engine, manual ones are electron-dependent - you can use them tens and hundreds of kilometers from the nearest access point to the power grid. They are very light, and therefore more mobile than their "brothers" with internal combustion engines or electric motors. Their main advantage is low cost. Yes, and you do not have to spend money on energy sources (electricity or fuel for the internal combustion engine) and spare parts (there is simply nothing to break there!). However, it is advisable to use mechanical concrete mixers only in the case when the amount of work is small and, therefore, little concrete is needed - for example, we can talk about building a cellar, concreting tracks on a site or repair and finishing works. For more large-scale construction, their performance will not be enough.

Specifications to consider when choosing a concrete mixer

Suppose you have already determined which type of concrete mixer best suits your needs - forced or gravitational, gear or crown, manual, with motor or electric drive. What other parameters should you pay attention to when choosing a specific model?

Volume

The performance of the concrete mixer directly depends on the volume of the working capacity. At the same time, one cannot say that mixers with a big drum are good, and with a small one they are bad, or vice versa - it all depends on the intensity and amount of work you are planning to carry out. On a large-scale construction site, a small concrete mixer will slow down the process - it will not be able to "give out" the necessary amount of concrete, and therefore the workers will stand idle. If the planned scope of work is small, then the purchase of a large concrete mixer is unjustified - it is, firstly, unlikely to pay off, and secondly, on a small facility it will take up too much space, and thirdly, a small amount of cement mortar will simply be smeared. its walls.

To make it easier for you to find out which concrete mixer to choose, select several size groups:

25-50 liter concrete mixers

They will help in the decoration of rooms (laying of ceramic tiles, plaster, etc.).

50-100-liter concrete mixers

Those who are going to build a small outbuilding (garage, cellar, bath, etc.).

100-200 liters of concrete mixers

Indispensable for the construction of a private house.

200-300-liter concrete mixers

Demanded for building houses of several floors - they can produce more than two cubic meters of mortar per hour that will ensure the continuous work of a brigade of 8-10 masons.

Power

Concrete Mixer Power - a parameter directly related to its volume. The greater the amount of concrete solution that the unit must mix during one cycle of its operation, the more powerful an engine it needs. Concrete mixers with a working capacity of less than 100 liters is enough engine capacity of not more than 1000 watts. With the solution of the problems faced by professional builders, such concrete mixers can not help. It requires more powerful models - with a drum of 300 or more liters and an engine capacity of 2000 watts. Such equipment allows to produce large volumes of ready-mixed concrete per unit of time and, at the same time, is able to work non-stop during the entire work shift.

Voltage

As a rule, powerful professional concrete mixers with electric drive are designed to operate from a three-phase network with a voltage of 380 V, and small household models are “satisfied” with 220 V, although, rarely, there are exceptions . Be sure to pay attention to this parameter, especially if you plan to work at a considerable distance from the access point to the power line - in this case, you will need a generator, and the voltage generated by it must correspond to the voltage of the equipment used.

Design features

The structural elements and parameters listed in this section are insignificant at first glance. However, if you do not pay attention to them when you buy a concrete mixer, it is possible that later you will be very sorry about this.

A device for unloading concrete . For unloading ready-made mortar from a concrete mixer, a special lever is provided in models of small volume or (more often) a steering wheel, which allows overturning the working tank and thus emptying it. If we compare the lever and the steering wheel, the latter is the most convenient option.

In large concrete mixers capable of preparing 300 or more liters of concrete mix in one cycle of work, a system of automatic loading and unloading is provided - a skip hoist. However, we are trying to figure out which concrete mixer is better to buy for the house, which means that such "giants" are outside our area of interest.

Wheels . Most of the relatively small concrete mixers are equipped with wheels, which makes it easy to move equipment around the construction site.

When choosing a specific model, it is necessary to pay attention to whether it has a device for locking the wheels and an additional reliable support at the base of the frame to increase stability during operation of the unit.

Working capacity of . Since the drum of the concrete mixer is its main working element, special attention must be paid to its strength.There are two technologies for the manufacture of drums - deep drawing on a hydraulic press and bending of cut steel sheets on rollers with their subsequent welding. The smooth sides of the working tanks made by the first method literally attract the views of potential buyers. But the main thing in a concrete mixer drum is not beauty, but strength, but in this case one has to doubt it. Such products are made of steel with a thickness of not more than 1. 5-2. 0 mm, which means that very soon they can leak. The drums made by the second method, because of their welds, are not so attractive from an aesthetic point of view, but being made from a thick sheet of metal, they are incomparably more reliable.

Bearing . There are two ways to position a concrete mixer bearing. It can be mounted inside a pear or inside a frame. The variant with the location of the bearing inside the pear is not a very good solution from a practical point of view. It is more difficult to change and it is often exposed to water and failure.

Bearing position inside the pear.

Bearing position inside the frame.

Overload Sensor . If you, deliberately or through carelessness, exceed the manufacturer’s recommended mass of the loaded components of the future mix and / or the non-stop operation of the concrete mixer, the engine may not cope with the load, resulting in its failure. To avoid this, an overload sensor will help, which will turn off the engine when the temperature in its winding is higher than a predetermined value.

Color of the concrete mixer . At first glance, the color of the concrete mixer is absolutely irrelevant. If you purchase a small unit that only you will use, this is true. If the concrete mixer is supposed to be operated on a large construction site, where several workers will be working at the same time, then we recommend that you do not neglect the rules of SNIP. The latter prescribe the staining of potentially dangerous equipment in bright colors - yellow, orange or red. This will help to avoid the occurrence of abnormal situations when someone from those present at the facility simply did not notice the working device, as a result of which the equipment itself may suffer at best, and people at worst.

Which manufacturers should be trusted?

It is very difficult to answer the question unequivocally, the concrete mixers whose production are the best today. Croatian Limex, Czech Zitrek, German Denzel are popular among builders. Those for whom a foreign label is not an end in itself, with pleasure use Russian-made concrete mixers, which are not inferior in quality to their foreign counterparts. Among them are “Prorab”, “Belamos”, “Profmash” and, of course, the Lebedyansky plant, whose products are consistently kept on the first lines of various professional ratings. It should be noted that the domestic technology has at least two indisputable advantages: first, it is designed taking into account the climatic conditions of our country, and second, it is much easier to find the necessary spare parts and consumables for it than for foreign ones.

Regardless of whether you are aiming at acquiring exclusively European technology or trust Russian manufacturers, we advise you not to focus in this matter only on the information contained in the advertising leaflets. Much more important is the opinion of real users. Talk with participants of various construction forums, talk with a friend who recently poured the foundation for the house on your site, ask the builders working nearby - and you can make your independent rating of manufacturers and understand which concrete mixer is better for you to choose.

We offer you to get acquainted with our rating of the best concrete mixers, based on user feedback.

Rules for operating concrete mixers

Now you have a general idea of how to choose a concrete mixer. It would be possible to end this conversation today, but I would like to say a few more words ... No matter what kind of concrete mixer you get - domestic or professional, expensive or cheap - when using it, you need to follow a few simple rules. Only in this case, your purchase will not disappoint you, the new equipment will last for a long time, and you will not become a hero in the chronicle of accidents.

| Before starting work, check the reliability of all threaded connections and, if necessary, tighten the bolts and nuts loosened during operation. Make sure that the unit is stable, set the drum to the working position recommended by the manufacturer.The subsequent launch of the concrete mixer at idle speed will finally make sure that the equipment is working and ready to work. |

| The mixture components are only loaded into the rotating drum. It is recommended to observe the following sequence: crushed stone is loaded first, then cement and sand, and only in the final is water. |

| The standard mixing time for the mixture components is 2-3 minutes. It is not recommended to increase the kneading time - the quality of the finished concrete will only worsen. |

| At the end of the work cycle, the drum is tilted with the neck down to unload the finished solution. If the work of the concrete mixer is not completed on this, the “pear” is returned to the working position and the cycle is repeated. |

| At the end of the work, the capacity of the mixer must be thoroughly rinsed with water. Do not delay this procedure for a long time, because the concrete quickly seizes. It depends on how thoroughly you clean the drum and other structural elements of the unit whether your next conversation with the mixer will be just as comfortable and pleasant. |

| Remember that a concrete mixer belongs to potentially dangerous equipment, so any repair and maintenance must be carried out only with the engine off . |

Video. The choice of concrete mixers