For many of us, the word "chainsaw" is strongly associated with muscular lumberjacks, who take a powerful tool in their hands and playfully cut down thick trees. But a chainsaw can become an indispensable helper for ordinary people who are used to doing everything with their own hands, and not rely on public services or someone’s help.

Prepare firewood for your home or bath, cut lumber for building small outbuildings, cut off thick branches of apple trees, forming their crown, or cut down an old tree under the window ... but who knows what other needs may arise? and works outside the city. Almost every owner of a country farm sooner or later makes the decision to purchase a chainsaw.

Which chainsaw to choose for home or cottage? What kind of chainsaws are there and what is their difference? How to choose them consumables and fuel? For those who buy such equipment for the first time, there are many such questions, and without answering them, making the right choice is difficult.

The device of the chainsaw and its principle of operation

The chainsaw belongs to chain saws. This means that its working element is a metal chain closed in a ring with saw teeth attached to it. During operation, the chain moves along the perimeter of the guide rail - the tire.

Powered by a chainsaw powered by a two-stroke internal combustion engine powered by a gasoline-oil mixture. The mixture of liquid fuel with air occurs in the carburetor, with its help the amount of air-fuel mixture supplied to the engine cylinder is regulated.

The engine is started by a manual cord starter. When this crankshaft spins. At one of the revolutions, the spark produced by the spark plug ignites the air-fuel mixture. The gas produced during the combustion of the fuel pushes the piston. The latter is connected through a connecting rod to the crankshaft, which by inertia goes to the second turn. The engine spins the sprocket, which in turn moves the chain.

The chiansaw runs on liquid fuel, which means that the fuel tank is one of its mandatory structural elements. Manufacturers try not to install too large tanks on the saws, since this would lead to a significant increase in the dimensions of the tool (and in the tucked state and weight). Most lightweight household models are equipped with a tank with a volume of from 0. 2 to 0. 5 l. Powerful professional chainsaws require more fuel, so their tank capacity can reach 0. 8-1. 3 l. The volume of the tank determines the duration of the operation without stopping for refueling.

Two-stroke engines do not work on pure gasoline, but on a gasoline-oil mixture. The oil coming along with the fuel lubricates the piston group and other "insides" of the engine. However, chainsaws have a separate oil reservoir - it is filled with a sufficiently viscous mineral grease for chains and tires.

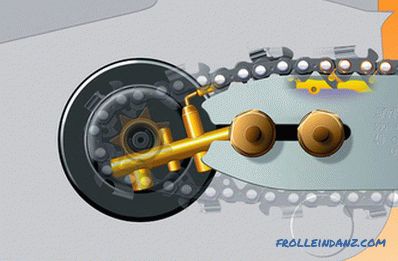

The chain needs constant lubrication, when working "dry", it wears itself and tires wear out. The faster the chain rotates, the more intensively it should be lubricated. On the other hand, when the engine is idling and the chain is stationary, it does not need lubrication. That is why chainsaw chain lubrication is carried out automatically.

1. Tire.

2. Chain.

3. Inertia brake of the chain.

4. Cylinder cover.

5. Starter handle.

6. Safety trigger.

7. Gas trigger.

8. Throttle lever.

9. Rear handle.

10. Oil tank cap.

11. Front handle.

12. Gas cap.

Types of saws: household, professional and semi-professional

According to their capabilities and their intended purpose, all chainsaws are divided into household, professional and semi-professional (often called farmers) - intermediate between the first two positions option. Between themselves, they differ primarily in power and built-in work resource.

Domestic chainsaws are designed for preparing firewood for the stove, cutting down trees on the plot, carrying out small-scale construction work, and other needs of the average resident of a country house. With the help of semi-professional saws, the same types of work are performed, but in a slightly increased volume of farming. Professional chainsaws are designed for logging work.

The power of household chainsaws is usually less than 2 kW. This is quite enough to solve simple everyday tasks. Felling of ancient pines in the taiga with their help you will not succeed, but to cut down the branches of fruit trees in the garden is quite under their power. Power "professionals" significantly higher - up to 6-9 kW.The power of the chainsaw depends on the cutting speed and the depth to which the tire will penetrate the wood.

Of course, there are no tasks for powerful units that they could not cope with. However, you should not mindlessly chase for great power. Among those who read this article in order to figure out which chainsaw to choose, there are hardly many professional lumberjacks. For operation in the household, a household or at least semi-professional model will be enough. After all, with low power, they have great dignity - low weight (up to 5 kg), which makes working with them easy and comfortable.

For comparison: the weight of powerful professional chainsaws can reach 10-15 kg (and for those who are cutting wood, this is not a disadvantage, since a large tool weight is significantly facilitates the process of sawing large tree trunks), it is not surprising that loggers are people of exceptional physical strength.

It should be taken into account that the actual weight of the chainsaw will be even greater, because the weight of the tool itself will add the weight of the completely filled tanks for fuel and oil and the weight of the saw headset. (To reduce weight, the crankcase and cylinder are made of aluminum or light magnesium alloys, and on some household chainsaws even plastic crankcases are sometimes put, which is less reliable, but easier and cheaper.)

Besides household power, semi-professional and professional chainsaws also differ in their resource, i.e., the operating time until the compression decreases by 40%, which means the engine will need major repairs. In this case, it is not only the total number of operating hours that matters, but also the time of continuous operation during the day.

The resource of household chainsaws is small (usually less than 1000 hours): they are designed to work no more than 20 hours per month (that is, less than an hour per day). Professional chainsaws can work without a break for 8-12 hours or more per day, and in this mode they can work for almost a year.

Chainsaw Engine

As mentioned above, the chainsaw is driven by a two-stroke engine. The main characteristic of any engine is its power. Engine power chainsaws, like any other engine, it is customary to calculate in "horsepower". However, for the convenience of comparing the characteristics of benzo and electric saws, this indicator is often indicated in kilowatts (1 hp = 0. 735 kW).

Of course, engine power primarily depends on its volume. So, for tools with an engine size of up to 50 cubic centimeters, the power does not exceed 2 kW, and for models with an engine size of 90 cubic centimeters, it can reach 6 kW.

The larger the engine, the better the performance of the saw. The cutting speed and the fitness of the saw for long work directly depend on the power. Suppose you need a chainsaw for harvesting wood for a bath; you are unlikely to spend more than an hour on this job. This means that a 1-1 saw will suit you. 5 kW. If we are talking about felling trees in the forest, then the chainsaw will be used every day for 8-12 hours. The best solution in this case will be a professional model with a capacity of 6 kW and more.

Air filter

The air entering the carburetor must be clean and free of dust. On chainsaws, the air filter is subjected to heavy loads because in the process of work a lot of dust and debris is created, which constantly rushes to the filter. As a result, the filter needs periodic cleaning. Well if the chainsaw has quick access to the air filter. Without the need to disassemble the case with a screwdriver or key.

To prevent frequent clogging of the filter, manufacturers use various devices to pre-clean the air. The simplest solution is the grid, which serves as an additional coarse filter. But the most effective solution is a centrifugal cleaning system. Its main node is the starter flywheel blades, which, rotating at high speed, discard debris from the air intake.

When the filter is clogged, air flow is impeded. This affects the quality of the working mixture of the engine and reduces its power. To solve this problem, some manufacturers complement saws with special carburetors with built-in compensators. Compensators regulate the flow of fuel depending on the incoming air. This provides a constant engine power despite the decrease in air flow.

Piston system of the engine

Number of piston rings. Pistons for engines that are mounted on chainsaws may have one or two compression rings. Engines with one ring on the piston, in most cases, are installed on household models. On the model of farmer and professional class install engines with two rings on the piston.

Engines with two compression rings have greater compression and power. There are some advantages for engines with one compression ring. Such engines have greater acceleration and easy start. Despite these advantages, it is better to give preference to engines with two compression rings on the piston.

Cylinder-piston group. Pistons and engine cylinders are made of aluminum. Since aluminum is a soft material, the walls of the cylinder are treated with wear-resistant coatings. Most often chromium or nicosil is used as such coatings.

Accordingly, the engine resource will depend on the thickness of these coatings. Chromium is a more durable material. However, Nikosil provides better oil retention and is able to reach full capacity faster. In addition, engines with such a coating are less afraid of overheating.

Crankshaft

There are two types of crankshafts mounted on chainsaw engines - stamped and forged. Stamping is used on some household chainsaw engines. Forged crankshaft more durable and all well-known manufacturers use it in their engines.

Engine crankcase

The engine crankcase can be made of aluminum or magnesium alloy, as well as plastic. Plastic cases put on the engines of household chainsaws and used to reduce the weight of chainsaws. Despite the fact that the metal crankcases are heavier, they are more durable and reliable.

Devices that facilitate engine start

It should be taken into account that when starting an engine with a large volume it is extremely difficult to overcome the resistance of compressed air. First, the fuel is sucked into the carburetor, then into the cylinder ... as a result, by the time when the air-fuel mixture could ignite and the engine, accordingly, start, there is usually no power left to pull sharply at the starter cord. Therefore, many chainsaws, and first of all powerful ones, are equipped with various mechanisms that facilitate engine starting:

1. Primer - a pump for pumping fuel to the carburetor (allows you to reduce efforts when starting the engine by 50-70%).

2. A decompression valve connecting the cylinder to the atmosphere to reduce pressure, which makes it easier to unwind the engine.

3. Spring starter , making it possible to pull out the starter rope slowly (only the spring is cocked, at some point it turns the crankshaft abruptly).

Selection of equipment for chainsaws

Tire of chainsaws

The tire of chainsaws is designed to guide the chain. In addition, it serves as a channel for lubrication. The length of the tire is one of the most important characteristics of the instrument, determining its capabilities. The longer the tire, the greater the depth of cut.

For example , a chainsaw with a 40 cm tire is capable of cutting a log 35 cm thick in one run.

However, when choosing the size of the working canvas, it is necessary to push off on the capabilities of the instrument, in particular on engine power. Long tires are put only on powerful professional tools. In domestic models, the length of the tire should not exceed 30-40 cm. If you plan to cut branches or thin trees, this is more than enough. Yes, and managed with a compact snap much easier. To roll thick trees you will need a chainsaw with a tire of 50-60 cm and more (up to 1 m): less time and effort will be spent on cutting each trunk.

In most cases, manufacturers initially complete their saws with tires and chains suitable for this model. Of course, if you wish, you can purchase the equipment separately. However, it should be remembered that the tire dimensions should correspond to the power of the tool.

The longer the tire, the more resistance the engine will experience. If you do not adhere to the recommendations in the instructions for the tool recommendations on the maximum allowable length of the tire, the engine load will greatly increase, and the life of the saw, respectively, will decrease. Not only productivity, but also service life of the tool, and safety of the worker depends on correctly picked up equipment.

What you need to know about the chainsaw chain

The saw chain consists of individual links fastened with rivets. Chains for chainsaws can vary in height profile, thickness and shape of the teeth, as well as the pitch of the chain. The last parameter is calculated by dividing in half the distance (expressed in inches) between three consecutive rivets.

The performance of the saw depends on the size of the chain step. It would seem, it is enough to put a chain with the maximum pitch on the chainsaw, and your tool will have no equal in the district. However, in practice, such a miracle to observe is, alas, extremely rare.Usually, when installing a chain with a too large step, the chainsaw refuses to work. This is explained very simply: a low-powered engine is not able to push the dimensional chain through the cut. The reverse situation also adversely affect the performance of the tool. A chain with a small pitch, mounted on a saw with a powerful engine, will slip through the wood, as if on ice.

Thus, if you want the saw to retain its functionality, you must remember the rule: you can replace the chain with another one, with a different step, but you can change this parameter in a small range. In general, the circuit must match the engine power. For light chainsaw models, a chain with a step of 0. 325 ″ is recommended, for more powerful ones - 0. 375 ″ or even 0. 404 ″. It should also be taken into account that the smaller the chain pitch, the less will be the vibration of the saw, which means that such a tool is better suited for use in everyday life.

There are chains designed specifically for sawing frozen wood. On their teeth are hard pokavitovye soldering. Such chains are too tough for ordinary chains, but the chain with taps is quickly dulled in soft wood.

Each link of a chain consists of two teeth - cutting and leading. Usually cutting tooth at 0. 5-0. 8 mm above the lead. This difference corresponds to the depth of the "penetration" of the tooth into the wood.

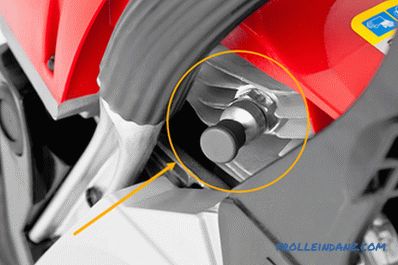

The length of the chain should correspond to the length of the tire. However, even a perfectly ideally fit chain gradually stretches during work and requires periodic testing and adjustment of the tension force. The chain is tensioned by tightening a special screw located on the tire.

Today, some manufacturers make the tensioner without tools, that is, not requiring a screwdriver or any other special tool.

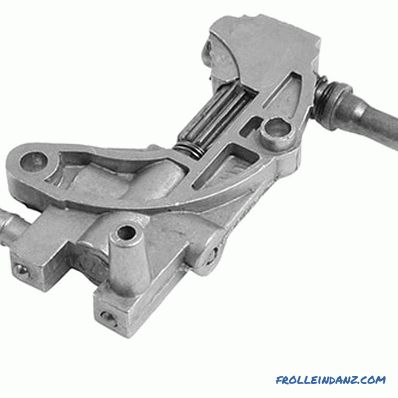

Oil pump

The chain moves along the tire during the sawing process and needs lubrication. When the chain stops lubrication is not needed. Therefore, chainsaws are equipped with an automatic lubrication system.

The main component of such a system is an oil pump. Pumps can be adjustable and unregulated. In adjustable pumps it is possible to change the oil feed rate to the tire, which is a convenient functionality. Adjustable pumps are equipped with professional and semi-professional chainsaws.

Oil pumps can be made of plastic or metal. Metal pumps are preferable because they are more durable, but they are more expensive.

Selection of a saw headset

By choosing a specific model of chainsaw, you are more likely to be in the future You will be forced to buy components from the same manufacturer. The fact is that the components of the saw headset - the chain, the tire and the drive sprocket - are not significant for different manufacturers, but they are different, and therefore, they are not interchangeable. The main differences between consumables from different manufacturers lie in the parameters of the leading sprocket and in the thickness of the chain link.

Note also that there must be a correspondence between the chain pitch and the parameters of the leading sprocket. Changing the chain to another, with a different step, will have to replace the asterisk.

Additional Functions

Anti-Vibration System

Professional loggers, who are forced to work with a chainsaw for 8 or more hours a day, very often suffer from joint diseases and blood circulation disorders in their hands, which is a consequence of the constant impact of strong enough vibrations. To save users from this problem, almost all professional chainsaw models produced today are equipped with an anti-vibration system.

It is a damper separating the motor and system of handles. The damper smoothes out vibrations from the engine running, as a result the vibration on the handles is felt to a lesser extent. The most darling variant of the implementation of the protected from vibration - rubber pads-shock absorbers between the body and handles. Reduce vibrations and manufacturers achieve by a precise adjustment of the mass ratio of the engine and the rest of the saw.

This function is useful not only for professional loggers, but also for those who use a chainsaw for domestic purposes - when harvesting firewood, in private construction or in the formation of the crown of trees. When working with a saw equipped with an anti-vibration system, you will be less tired, it will be easier for you to hold and guide the saw.

Protective functions

The chiansaw is a potentially very traumatic tool. Of course, the safety of your life and health depends primarily on yourself, but rather on the thoroughness of your compliance with the rules of operation of the tool. However, manufacturers are trying to do everything possible to reduce the risk of users of injuries when working with a chainsaw to a minimum.

Most often, troubles arise during the so-called reverse impact — when, as a result of the front part of the working canvas touching the surface with increased hardness, the saw is sharply thrown back. The surest way to prevent user injury at this point is to instantly stop the circuit.

Two systems are used to lock the chain in the opposite direction. The first is a button mounted on the handle of the chainsaw, which must be held simultaneously with the start trigger. When the saw sharply jumps as a result of the kickback, the filer reflexively releases this button, and as a result the chain is blocked.

The second system is to install a special lever in front of the operator’s left hand. At the time of the return strike, the sawman’s hand rests against this lever, which was placed before starting work on a platoon: the lever is activated - the chain stops.

What you need to know about gasoline and oils used in the operation of chainsaws

Before you finally choose a chainsaw, you should at least get a general idea of what This "beast" to feed. The two-stroke engine is installed on chainsaws, which means that the tool is not filled with pure gasoline, but with its oil and oil mixture, and the ratio of components is strictly regulated by the manufacturer.

Even 76th gasoline is suitable for domestic chainsaws (if you manage to find one today) and the cheapest oils for two-stroke motorcycle engines (the recommended ratio of oil to gasoline is 1:25). Imported models are more whimsical: for normal operation, they require gasoline with an octane rating not lower than 92 and a firm "two-stroke" oil (the recommended proportion, as a rule, is 1:40). In principle, ordinary motorcycle oils are also applicable to bourgeois saws, but only if the engine revolutions per minute do not exceed 8. 5 thousand, otherwise such a substitution will lead to a decrease in engine life.

It is possible to store the prepared gasoline-oil mixture for no more than two or three months, but it is advisable to use it for two weeks. The fact is that gasoline in such a mixture, even if it is stored in a tightly closed container, gradually oxidizes. When using an "aged" mixture, the engine, as a rule, wears out faster. At the same time professional chainsaws are more sensitive to the quality of the fuel mixture than household ones.

Chain oil is poured into a separate tank. Here you can easily do without expensive imported lubricants. But when choosing oil for the chain should take into account the ambient temperature. Mineral oils, which perform well in summer, begin to crystallize in the cold. When working in the winter, it is better to use synthetic oils - they are less viscous and retain their properties at air temperatures of up to -40 degrees.

Chainsaw manufacturers who have proven themselves in the market

How to choose a chainsaw in terms of price and quality? Most of the domestic market for chainsaws is divided between major European brands. Due to their quality, their products are highly valued not only in Russia, but throughout the world. The Asians, who are equally easy to produce any kind of equipment, are not far behind them.

Undoubtedly, you will not lose if you buy a chainsaw from Husqvarna, Stihl or Hyundai. But we should not neglect the products of companies offering low-end models. The chainsaws they produce are sometimes less reliable, but even they find their buyer because of more affordable prices, because the choice of a better and more expensive tool often turns out to be completely unjustified. How justified is the overpayment for reliability, efficiency, functionality and the well-known name on the nameplate - you decide. In the end, it largely depends on the tasks you are facing and the budget instrument you have to buy.

Let's compare the products of the most popular brands in the domestic market and analyze the customers' opinion about these chainsaws.

Stihl

The universally recognized market leader in chainsaws today is the German company Stihl. Despite the already won popularity, Stihl does not stop there and continues to improve its products. For example, on their chainsaws is installed the engine 2-MIX, characterized by a 20% reduction in fuel consumption and a reduced level of harmful emissions by 70%.

The company produces chainsaws of all classes — domestic, semi-professional and professional; it also has a special line of saws designed for rescuers. With such a wide assortment, a large price range is not surprising - from 17 thousand rubles for household chainsaws to 50 thousand or more for powerful professional models.Tools Stihl according to user reviews are of very high quality. Recently, however, a huge number of fakes have appeared on the market, so you should carefully consider the choice of a reliable seller.

Husqvarna

The Swedish concern Husqvarna is the world's largest manufacturer of chainsaws and other tools for farmers and gardeners. Their products are represented on the market by household, semi-professional and professional chainsaws. The price range is from 15 to 30 or more thousand rubles, depending on the class of the instrument.

In general, Russian users are delighted with the quality of Husqvarna chainsaws; even the cheapest models collect a lot of positive reviews. The only moment that causes dissatisfied users is the high cost of consumables and spare parts. However, today the owners of all chainsaws of European production face a similar problem.

Emak

The products of the Italian company Emak, the owner of the Efco and Oleo-Mac brands, are not yet well known to Russian buyers. Meanwhile, those who had a chance to work with Oleo-Mac saws were very pleased with this tool. In the assortment of Emak many budget chainsaws, the price of which varies from 14 to 20 thousand rubles, as well as saws of the middle class.

Partner

Partner, born in the 1950s, was originally engaged in the production of professional equipment for loggers. After 30 years, she expanded her product range, starting to produce tools for gardeners. Today, Partner is part of the Swedish concern Husqvarna, but its market segment is very narrow: Partner specializes exclusively in the production of low-end models of household chainsaws.

Production is located in the Middle Kingdom, but this does not affect the quality of the product: for its price category (6-15 thousand rubles) it is very good, as evidenced by the feedback from the owners of Partner chainsaws.

Hyundai

The South Korean company Hyundai, known primarily for its cars, also produces a whole range of agricultural tools, including chainsaws. Owners of Hyundai saws appreciate them for the high power and reliability of the engines, as well as for the very affordable price. However, let us be honest and note a number of shortcomings that Hyundai products are not without. The body of most models of chainsaws is made of plastic, which is not very practical, and even this did not help to reduce the weight of the tool. Potential buyers are not satisfied with the extremely poor assortment of saws from this manufacturer.

This is not all the leaders of the domestic market for chainsaws. The range of professional and amateur saws today is so great that everyone will be able to find a tool to their liking and afford it. Visiting the store, be sure to pay attention to the products of German companies Huter, Dolmar and Al-ko, Japanese Makita and Kioritz Corporation (the latter is the owner of such brands as Shindaiwa, Echo and KIORITZ,), American Patriot, Chinese Champion and Carver. These chainsaws, of course, will be able to cope with all, even the most difficult tasks set before them.