Usually, the installation of smoke exhaust ducts is carried out during the construction of the building. But there may be situations when, after the completion of all work, there is a need to install furnace heating or a fireplace. In such situations, it is important to know how to get the chimney through the wall.

Two sides of the coin

The location of the chimney inside the wall is more familiar and allows you to hide unnecessary communications, but the outdoor installation carries many positive points:

- Increased fire safety. There are cases when accumulated soot ignites. It burns at a temperature of + 1200ºC. This heat does not withstand any material other than ceramics. If this happens to a pipe that is embedded in a wall, then a fire cannot be avoided. If a similar situation develops with the external structure, then the consequences will not be so disastrous.

- Lack of smoke. Over time, the exhaust system can become unusable and smoke begins to leak through the cracks and into the room. This will not happen if the channel is on the street.

- Saving of useful space. The internal location of the chimney implies that it will occupy a certain living space.

- Possibility of installation after completion of construction.

- No need to interfere with the integrity of the roofing.

- The advantage of elevating to high altitude for improved traction.

Chimney bracket

Chimney bracket

The disadvantages include:

- Significant windage at high altitude.

- Need for additional mounting material.

- The importance of proper pipe insulation.

- Significant heat loss.

- In some cases, the type of chimney style of the building.

General requirements

In order to ensure sufficient traction, it is necessary to meet a few simple requirements that apply to any chimneys:

- It is important to know how to correctly calculate the correspondence of the channel section and the power of the stove, fireplace or boiler. If the passage is narrowed, then the smoke will not have time to go out and will fall into the room, because there will not be enough traction.

- The optimal chimney height is considered to be 5 m. In some cases, due to the presence of buildings or other obstacles in the vicinity, it will be necessary to raise the canal even higher.

- It is important to carefully select the material to be made.

- The priority will always be round. It does not cause turbulence, which can cause bad or reverse thrust.

- If the channel is located next to the roof where there is a risk of fire, then a spark arrester will be installed. This is a metal grid, the dimensions of which are 0.5 * 0.5 cm.

- The length of the sun beds (the horizontal part) should not exceed 1 m in length. If you do not follow this rule, then the craving can be bad. Also, these areas will often be clogged due to accumulation of soot.

- The house should have good ventilation.

- It is important to provide a moisture condenser, as well as openings through which it will be possible to clean soot. Special openings are left in the brick construction, which are closed with a brick on the mortar and an additional door.

- It is better to avoid right angles and replace one with 90º by two for 45º each.

The choice of material

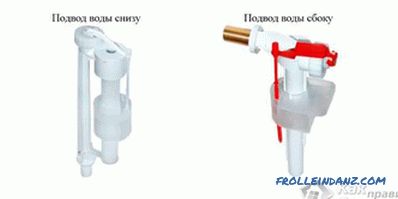

Additional elements of sandwich pipes

Additional elements of sandwich pipes

Today there are a large number of ready-made solutions for the arrangement of the chimney, but some prefer to go the proven way and do everything on their own.

- Brick. A good option if you make a chimney for a conventional stove or fireplace. The advantage of this material will be the possibility of combining it with the overall exterior of the building. Also, warming is not required with proper calculation and installation. If you need a high enough design, it will be very overall.

- Stainless pipe. It is especially relevant when acidic emissions are possible. In this case, it is better if it will have molybdenum in its composition. The disadvantage is the need for its good insulation. If this is not done, too much condensation will accumulate, which will worsen the draft.

- Double or sandwich pipes consist of two metal sleeves. One of them is located inside the other, and the space between them is filled with insulation. They can both be stainless steel, or only internal, and external - from galvanization. It is supplied in blocks, so the assembly does not cause much difficulty. There are adapters that allow you to connect them to the pipe coming out of the stove or fireplace.

- Ceramic tube. A great option that withstands high temperatures. Also needs warming. The downside is the relatively high price and structural fragility.

Brick or concrete wall

The removal of the chimney through a structure of this kind is much easier, because these materials themselves are not combustible. The sequence of work will be as follows:

- The location of the heater is determined.

- Markup is done.

- There should be no communications in the wall. They can be damaged during installation work.

- A hole is made with a hammer drill or a jackhammer. Better if it is round. This can be achieved using a special crown. If it is absent, you can draw a circle and use a smaller diameter drill to drill holes abreastly in a circle. After that the material located in the middle is taken out.

- A solid piece of pipe is laid through the wooden wall. Ensure that there are no joints inside the wall. Otherwise, if they diverge, smoke can go inside. To fix this is quite difficult.

- The cracks formed are eliminated with the help of a special heat-resistant insulation.

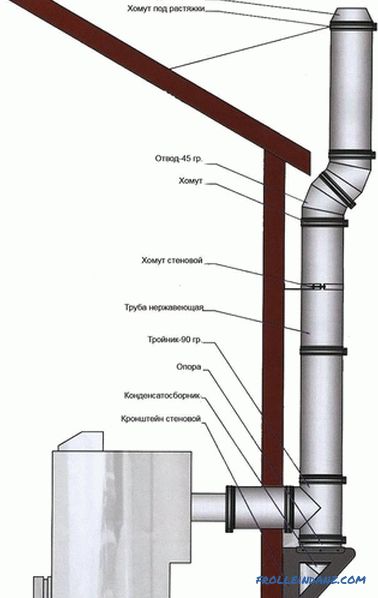

- Depending on the height of the hole, it is necessary to install a support stand. If there is a short distance to the earth, then it is possible to make a foundation for a support. To do this, dig a hole 50 cm deep, make sanding and ram. Further, with the help of fittings, the lathing is made and placed in the middle. Everything is poured concrete and stands. You can immediately concreted metal columns. Another option is to mount to the wall. For this, a metal frame is made of a corner. Suitable profile from 25 * 25 mm. In the lower part, several corners are mounted, which also abut the wall for greater rigidity. This is all fastened with anchor bolts or HEX self-tapping screws.

- A tee is mounted on a stand, at the bottom of which a condensate trap is located.

- Next, the entire chimney structure is assembled. If it is a sandwich panel, then they are simply interconnected and fixed with a special clamp. Stainless steel pipe must be jointed with welding seams.

- Installation to the wall is carried out using special fixings. The distance between them should be 60 cm, but not more than 1 m.

- Make sure that the pipe joints do not fall into the clamps that hold the structure to the wall.

- It is better to bypass the roof departure without using horizontal sunbeds, since this will worsen the thrust in the channel.

- If the upper part of the pipe is located near the ridge, then its departure should be at least 50 cm.

- In some cases, additional stretchings are installed if the pipe is at a great distance from the wall.

- In the case when the chimney is not from sandwich panels, it must be insulated. This is done with the help of basalt wool, which is then covered with a dense foil.

- A special peak is mounted on the top, which will prevent the penetration of precipitation into the middle.

A brick chimney is usually built close to the wall to ensure its stability. In this case, it is important to correctly calculate its internal and external size. If a mistake is made, then the walls can overheat, which will lead to sad consequences. In the lower part of the design also provides a compartment for collecting condensate. The connection of the heating device and the brick channel is carried out using a stainless steel pipe.

Wooden wall

The principle of mounting through a wooden wall is similar to that described above, but there are some precautions that are important to follow.

- A hole is made, the diameter of which must be calculated in such a way that a distance of at least 450 mm from the central tube, which will be heated as much as possible to the combustible material.

- In order for security to be at the maximum level, it is best to use a sandwich panel for output.

- The space around the pipe is filled with basalt insulation. It is very resistant to temperature. The highest value reaches 1000ºC.

- Provide for a gate (damper) that can be closed during the summer time or when the system is not in use.

- A sheet of galvanized sheet or stainless steel is packed on the outside and inside that will hold the cotton inside.

- When attaching the pipe to the wall, it is necessary to observe a gap of 10 cm to ensure fire safety.

- Installation of spark arresters will be a prerequisite.

Sandwich pipes

Sandwich pipes

If you want not to worry at all about for the fact that there will be bad traction, it is possible to provide for the presence of a deflector. This is a special umbrella that is installed at the top of the pipe and contributes to a greater pressure drop. There are options that turn themselves in the wind and the flow pulls smoke behind them.

Street wall chimney

Street wall chimney

In this way, the pipe can be removed in the bath as well in the garage. Before you do all this, it is very important to make scrupulous calculations, so as not to miscalculate with the size and height. Do not save on materials. In the end, the reliability of the whole structure can depend on your life as well as the life of your loved ones.

Video

How to make a chimney out of a sandwich pipe will be discussed in this video: