One of the highest quality and reliable building materials is wood. The naturalness and the "softness" of the wood make it possible to build very good buildings. But if the construction team irresponsibly reacts to the quality of fastening, then such a house, not only will not stand for a long time, it can also pose a threat to its owners. Therefore, it is very important to know how to fasten the timber between them correctly.

The reliability of a wooden house depends on how the timber will be attached to the timber.

Some features of the timber

It is believed that the customer is always right, but many builders begin to impose their opinion. And then disputes can arise. One of these controversial points is the choice of timber or logs. In order to answer this question, you need to know some of the characteristics of these materials.

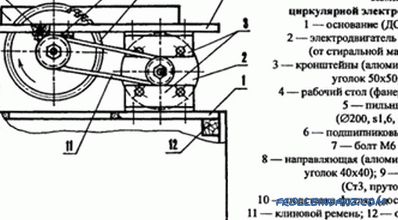

Schemes of rigid fastening of timber.

Logs have very high frost resistance and have good resistance to winds, preventing drafts from cracks. But the creation of log walls is a very difficult job, requiring knowledge and skills, and even better a highly skilled carpenter. Independent production of logs from logs threatens to lead to failure. Logging is a step-by-step process, because after cutting, they are given time to shrink and only after that they are installed.

Timber is the same wood, only already mechanically processed in production. Its thermal conductivity properties are similar to logs. The only, connecting seams of bars are more blown. But even with this problem we found how to fight: it is necessary to use alternation of bars with different heights. Thus, the seams are reduced, and as an addition, use special gasket materials and insulation.

When building walls out of a bar, the need for scrupulousness of work is much lower. So, besides a professional, both a beginner and an amateur can cope with this task. A very big convenience is that the bar has minimal shrinkage. Therefore, it is almost immediately spread on the foundation.

If you objectively evaluate logs and cant, in the second case you need 2-3 times less time for construction work than in the first. This saves time, financial and human resources.

Principles of the correct connection of the timber

The method of fastening the timber using the soft method with the help of brackets.

Since the corner joints of the timber construction are rather weak, then various insulators are used to eliminate this disadvantage. For this purpose there are several types of connections, not only for the angle, but also for internal walls, rafters and beams.

Each place has its own purpose, therefore, in order for the whole building to fulfill its functions, it is necessary to properly fix the timber in all places.

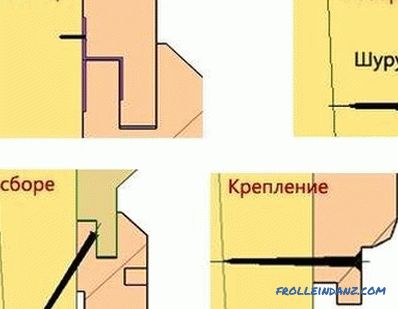

For corner bars, connections such as end-to-end, with or without residue, have been developed. From the inside use T-shaped connection.

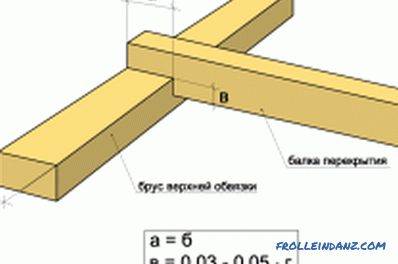

Longitudinal fastening of the beam is provided with the help of dowels, root cleat, oblique or direct lock.

For such a material, this compound provides maximum strength and reliability. To make it easier to work, you should act on a specially designed template. The main thing is to observe the evenness of the lines and control that the bars fit snugly together. As already mentioned, the corner joints are additionally insulated.

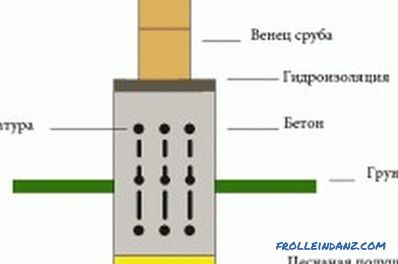

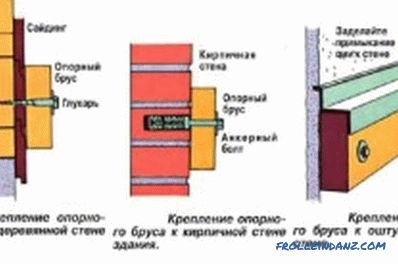

Schemes of fastening the beam to the wall.

The choice of the right tools also plays an important role. For example, without an ax it makes no sense to take a log house. A saw, handsaw, hammer and mallet act as an auxiliary force.

The most common joint for corners is the joint with the remainder and the locking groove. The size of the groove is oriented at half the thickness of the tree. This type is mainly intended for the first crown.

Further fastening is provided by means of root spikes or dowels. This avoids unwanted horizontal or vertical shifts.

"Lock" can also be used for compounds without residues. For these purposes, it is necessary to have pins with a cross section of 30 mm and a length of 25 mm. The beam is laid on the tow, and then the holes for the pins are made. At this stage it is important to compare the height of the beam and the depth of the aperture. The second should be at 1.5 levels above the length of the log.

Newbies are most often built with butt joints. Of course, this method is the easiest, but it has many nuances. First, with this option, the building is vulnerable to wind, respectively, in the house there will always be drafts. So, the heat will not stay there for long. Secondly, during frosts the building will be cooled very much.

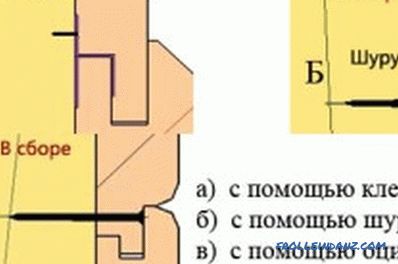

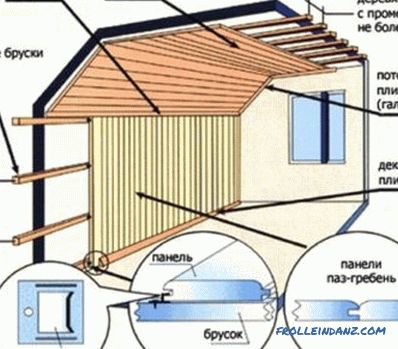

Options for attaching the vertical uprights of the frame to the bar of the bottom trim.

In this embodiment, the connection of two bars with metal plates, nails with spikes is provided.Two elements are laid on the supporting part, after which both ends are fastened with staples.

A T-junction requires nogs. Thus, the most reliable fastening from all available is reached. Additionally, joints with a lock and straight groove, as well as a symmetrical or rectangular trapezoidal spike can be used. The latter help to contain the connections so that they do not loosen and spread. Of course, in order to make such a spike, you must have patience and time. Therefore, he is not so popular among professional builders. But the nog is another thing. Joints in the corners strengthened with staples, bolts and nails.

The advantages of correctly fastened profiled or glued timber

Although wood has been used in construction for a long time, it also has a number of "uncomfortable" features. Firstly, the surface of the wood does not have perfect smoothness. Secondly, while working with it, a large number of burrs and knots are obtained. If the material does not work properly, it will be too vulnerable to cold winds, which will significantly affect the quality of living inside such a building.

A rope is passed through the holes and fixed at the ends with knots.

It was the correct technology for the production of lumber allowed to negate these shortcomings. A prominent representative of such a "struggle" is a profiled beam. The finished material has on its surface special grooves and ridges. They provide a denser joint, respectively, and higher quality joints. Given the profile, the methods of combining profiled materials are similar to ordinary timber.

For the sake of fairness, it is worthwhile to immediately indicate that the cost of such material is quite high, since the consumption of wood in the production process is very high.

Therefore, more preferences are given to the glued counterpart. Such a timber consists of lamels separately glued together, which lie in fibers that do not coincide with each other. Such material is initially sharpened to a smooth surface, impregnated with special solutions that will protect the house from rotting and fungi.

The profiled bar has good fire resistance, similar to metal structures. Glued analogue is lighter, which allows significant savings on the laying of a heavy foundation. But again, preferences depend on the individual wishes of the customer.

Wood has a very bright and unique structure, thanks to which the buildings made of it look really interesting and attractive, the main thing is original.

Didn't find the answer in the article? More information on the topic:

-

How to fix Euro-rail correctly?

Step-by-step instructions on how to fix the lining with your own hands. Materials and tools needed for work. Installation of this coating using klyaymerov.

-

Guide to trimming a balcony with a tree

The process of covering wood balcony. The necessary tools and material for plating. Warming and creating a frame for plating. Features trim the walls of the balcony or loggia.