Every person dreams of his own dwelling in which his family will live. Over time, construction technologies have made great strides forward, therefore it is not necessary to be limited to materials such as brick and wood. Today there are new materials for construction, one of which is aerated concrete. A house of such material will serve you for many years without losing its original characteristics during operation. After reading this article, you will learn how to build a house from a gas block with your own hands.

Advantage of a gas-block

Advantages of a gas-block

Advantages of a gas-block

Aerated concrete is a great alternative to brick, so as it is distinguished by its good thermal insulation properties, reliability, durability and durability. This material has already won respect from most builders and developers, as it has many advantages. What are they?

It is for these characteristics that gas-blocks are gaining more and more popularity:

- Aerated concrete has a low thermal conductivity, so buildings from it have much better thermal properties than brick houses, concrete or wood.

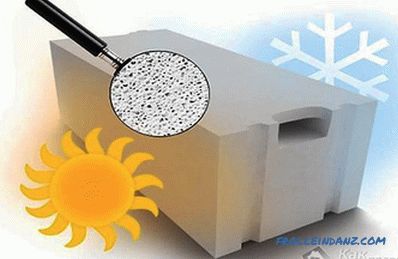

- The porous structure of aerated concrete gives the walls high air and vapor permeability. Houses built of gas blocks have a constant adjustment of air humidity and circulation of air, which creates a good microclimate, the same as in natural wooden houses.

- Gas blocks are made to exact dimensions with minimum tolerances and a smooth surface, so you can use special glue when laying the walls, which will speed up the construction process and prevent the formation of cold bridges during operation. Also, the process is accelerated due to the large size of the blocks.

- Aerated concrete fire-resistant and environmental material.

- The material has a porous structure, due to which the weight of the blocks and, accordingly, the load on the foundation is not the same as that of other building materials. This allows you to reduce the cost of building the foundation.

- Due to its high strength, aerated concrete does not break, does not crumble, and retains its original appearance.

- According to many experts, the building of aerated concrete can last more than 30 years.

- Aerated concrete has a high absorbent surface that allows you to set well with plaster and other materials.

Such advantages make it possible to use the material for building your own house.

Because of its porous structure, aerated concrete easily accumulates moisture and is able to store it for a long time, and this will lead to freezing of walls and the formation of mold on them. Therefore, during work and during further use, the material should be protected from external factors.

What you need to know before building

What you need to do before building a house

What you need to do before building a house

If you build your home for the first time, you need to know that the first thing you need to do is paperwork. After all, just to build a house on the site no one will give you. First you need to get a building permit to be approved by the authorities in your area. Therefore, it is necessary to prepare the necessary documents, among which is the plan for future construction.

Not everyone can make drawings at home, for this requires special education. Therefore, you can contact the specialists who, for a certain amount, will be able to transfer your dream home to paper. Another option is to surf the Internet in search of a project at home. In this case, be careful, because you do not know who made them and whether it is right.

Such a plan must have:

- a foundation;

- floors with cuts;

- a truss roof structure and calculation of the roof surface;

- door and window openings.

It is necessary to determine the design of the building in advance. Aerated concrete can be cut, so you can make a variety of arches, columns and beautiful openings. There are many options, the design may be different, depending on your desire.

Another important point before the start of construction is to purchase material. To avoid additional financial costs, you need to buy as many blocks as you need. But how to calculate the aerocrete on the house so as to avoid the shortage and excess material? Here you need to take into account the size of the house and aerated concrete blocks. The first thing you need to know the area of the walls.

All dimensions must be in the house plan. For example, one wall has a length of 12 m, and the other - 10 m. There will be two such walls. All they need to add:

12 + 12 + 10 + 10 = 44 m

It turns out that along the perimeter we have a length of 44 m. But, the house also has height, so it must be multiplied by the perimeter. Suppose the height of the house is 4 m.Then it turns out:

44 * 4 = 176 m 2

Total, the area of the walls of your house is 176 m 2 . Based on this data, you need to calculate the number of blocks that are sold in cubic meters. For this, the block thickness (0.3) must be multiplied by the area:

176 * 0.3 = 52.8 m 3

So To lay out the outer box at home, you will need 53 m 3 gas blocks. For interior walls, the calculation is the same. Consider that it is undesirable to take a material back to back; it is better to drop 10% above so that you have enough blocks during construction.

When transporting, the blocks should be covered with a hermetic film so that moisture does not destroy the material even during transportation. Moreover, aerocrete need to be strengthened, so that after delivery they are not damaged, taking into account what kind of roads there are.

It is necessary to store aerated concrete in a dry place where it will not get wet. Cover it under a canopy to avoid precipitation. It is important to provide a flat surface to lay the blocks. Then the material will be stored correctly, without losing their qualities.

How to fasten gas-concrete blocks with mortar or glue?

Cement and glue

Cement and glue

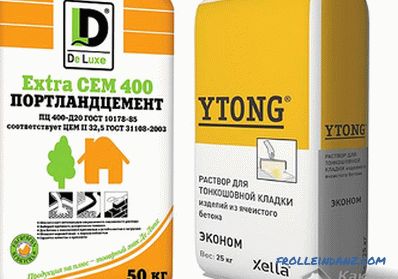

As mentioned earlier, one of the advantages of a gas block is that it can be fixed either with a conventional solution or with a special glue. What material to choose for work? It should be borne in mind that each of them has both certain advantages and disadvantages.

There are the following advantages in using glue:

- perfect joints;

- very smooth laying of walls;

- there are no cold bridges;

- it is easier and easier to work with him.

But it is important to consider that:

- during operation, the adhesive will release various toxins;

- its price is much higher than that of a solution.

The usual solution consists of water, cement, and sand. Of the minuses, it should be noted that it is somewhat more difficult to lay the brickwork than with the use of glue, since it is constantly necessary to monitor the masonry evenness. But to correct these irregularities using the solution is much easier.

There are no certain rules or laws when choosing. Based on the foregoing, you can determine which material to use.

Preparatory work

How to start building a private house

How to start building a private house

To build a house of aerated concrete, first of all you need to do some preparatory work, without which construction will not start:

- first thing you need to provide electricity on a building site so that the light is and the tool can be connected;

- organize a place for the storage of aerated concrete;

- prepare a place that will serve as a warehouse for consumable building materials;

- deliver the necessary inventory to the object, inst instruments and equipment;

- bring the material necessary for work (aerated concrete, cement, sand, crushed stone) for at least a week of work;

- make geodetic training;

- study the floor plan, techniques and ways of doing work and organize workplace safety.

It is necessary to perform laying at a temperature of 5 to 25ºC. If the temperature of the medium is above 25ºC, then during the performance of work, the gas concrete must be constantly wetted with water.

Construction technology

Construction of aerated concrete blocks

Construction of aerated concrete blocks

Construction technology houses of aerated concrete blocks began to be used in Europe, from where she came to us. For many years, aerated concrete is a popular material that has proven itself due to its properties. For many decades, such houses have been located in most countries of Canada, Asia and Europe.

Many people without construction experience know the technological order of the work in general terms. Let's take a detailed look at what needs to be done to build a building:

- Construction of the foundation. Due to the fact that aerated concrete is relatively lightweight, it is not necessary to make a reinforced foundation, it all depends on the number of floors, the location of groundwater and the type of soil at the construction site. Basically for the house from the gas block choose a tape or monolithic foundation. Work on his device can last 3 weeks or more. Please note that the porosity of the material contributes to increased water absorption, so be sure to carry out waterproofing work, paying special attention to them.

- Masonry walls. It is much easier to erect walls from a gas block than from a brick. Since the blocks are large and smooth, it can be done very quickly. The main thing is to choose a clutch and strictly adhere to the scheme. If the house will be with two floors and more, it is important to strengthen the walls, making the construction reliable and durable.Reinforced belts are used for this, then the perimeter of the house will be further strengthened.

- To lay the walls, use a mortar or special glue, which is applied with a special tool or comb blade. Thanks to it, you can achieve a smooth millimeter layer of technology. To align the blocks by level, a rubber mallet is used, which is tapped on top of the block. This will not damage the unit and will ensure uniform laying. It should be noted that the walls of the gas block after construction practically do not shrink. It turns out that it is possible to carry out finishing work immediately, due to which the construction juice will decrease significantly.

- House overlapping is an important part of construction. For a gas concrete house they can be monolithic, made of wood, concrete slabs or combined.

- Another important stage is the construction of the roof. You immediately need to calculate the roofing surface, purchase the material and make the roof truss system, and also sheathe it with roofing material.

- Glazing of windows of the finished box. Double-glazed windows should be selected to provide sound and heat insulation.

- After that, you need to carry out interior decoration: lay engineering communications, such as sewage, water supply, heating, electricity, equip the foundation of the floor, build internal partitions, prepare the surface of the walls for finishing and complete it.

- Final finishing of the facade. At this stage, the eaves of the eaves are hemmed to the roof, and a water drainage system is installed. Well, there is a wall finish. Thanks to it, it is possible to achieve the following goals: to level the surface, hiding unevenness, protect the material from mechanical damage and moisture ingress, give the house a beautiful aesthetic look.

- The last stage is landscape design. You can decorate the plot, plant it, build a fence and make a decor.

If you stick to these technologies, your house will stand for a long time without losing its qualities, it will be cozy and warm, and fungus and mold will not disturb you.

So, theoretically, you are already prepared, you can proceed to practice to learn how to build a house with your own hands.

Start of work - preparation of the foundation for the foundation

Tape foundation

Tape foundation

The first thing you need to do, mark the site on which the house will be built. This is done for orientation, to dig a trench under the foundation. For this you need a rope, a hammer and stakes. Further according to the scheme:

- clear a place for building: remove debris and disturbing objects, if the place is overgrown with large weeds, they also need to be removed;

- now make the markup. To do this, starting from the drawings, drive the stakes in the corners of the building. It should be noted that the strip foundation is built under each wall, repeating the contour of the building. That is what you need to do on earth. By this marking, you will dig a trench, so everything needs to be done exactly, keeping the dimensions and width of the foundation;

- after the stakes are packed exactly, you need to measure the diagonals. When they coincide with the drawings, feel free to stretch the rope between them.

Tighten the rope tightly so that there is no sagging.

Now you can proceed to the next step - digging a trench. Digging the trench begins with finding the lowest point of the plot. It is necessary to calculate the depth of the foundation from it. Note that the size of the finished pit should be identical to the size of the house based on the project.

For work, you will need shovels and labor, since it will not only be hard, but long, to do all the work yourself. In extreme cases, if circumstances permit, you can hire a special technique. The walls of the trench must be made vertical and the bottom flat. To check this, in the process of digging, use a plumb, as to fix something after completion will be more difficult. The depth of the foundation depends on the soil and the height of the building. It can be shallow - from 50 to 70 cm for small houses, and recessed - from 1 to 2 m.

Be sure to make a pillow for the foundation at the bottom of the trench. Put sand or crushed stone there in a layer from 10 to 20 cm. Tamp everything down well and place a layer of roofing material on top. This will provide good waterproofing, not allowing the foundation to absorb moisture.

Formwork and reinforcement installation

Formwork device

Formwork device

From boards, plywood or other wooden materials need to assemble shields. It is possible to connect elements among themselves with self-tapping screws or nails. If you live in areas with a harsh climate, raise the formwork 40-50 cm above the ground level so that the walls under the layer of snow do not freeze. And when the climate is not so severe, the base can be made 30 cm. Then stretch the line along the perimeter so that it corresponds to the level of concrete pouring into the foundation.

This stage includes not only the formwork device, but also carrying out the necessary communications. After all, if you do not do it in advance, holes for sewer or water supply will need to be done in the finished foundation.

To strengthen the foundation, you need to place the reinforcing mesh in it. She will be placed in the formwork. To make such a frame, you will need rebars of Ø14 mm and steel flexible wire. Bars need to be tied up with a wire. When making cells, sticking to certain sizes is optional. On average, these cells are 20 * 20 cm in size equal to the size of the trench.

In order for the concrete to completely cover the reinforcement mesh, it must not be installed flush with the top of the trench, but lower by 5-10 cm.

Now everything is ready for pouring concrete.

Filling the foundation

This stage of the work can be divided into several steps:

- Determining the desired volume of concrete. To calculate how much the mixture will fill, there is a formula: V = S * L, where:

V is the desired volume of concrete,

L is the length of the foundation,

S - cross-sectional area.

And to know the value of the area, it is enough to multiply the height of the tape by its width. For example, the length of the base strip is 44 m, height is 1.3 m, and width is 0.5 m. To determine the section, we will multiply the height by the width: S = 1.3 * 0.5 = 0.65 m 2 . After which: V = 44 * 0.65 = 28.6 m 3 . It turns out that 28.6 m 3 of the concrete solution will be needed to fill your foundation. - Now you need to decide whether to order concrete from a construction company or make it yourself. The easiest way is to order a solution - it will be quickly, without any extra effort, only now the service costs more. If you want to save money, you can make concrete yourself, this process is more labor intensive. It is better to have a concrete mixer, because manually mixing such a large volume is unrealistic. To make concrete quality, strictly follow the proportions: 1: 1: 3 - cement, crushed stone, sand. Water must be added until the mixture becomes the necessary consistency.

- If you have never cast concrete, you should know that it is wrong to dump all concrete into a trench. It is important to pour concrete in an even layer of 20-30 cm so that the concrete comes out monolithic. Haste in this matter is not needed, since the foundation is the foundation and support of the house, which allows it to stand for a long time.

- It is important to expel the air from the concrete, ramming each layer. To do this, use the vibrator. If this is not available, simply compact the concrete with a stick or reinforcement. Fill hold until you reach the line level. To better tamp concrete, tap a mallet on the formwork from the outside.

- After the completion of pouring, the surface of the foundation must be leveled using a trowel.

Concrete needs to be covered

Concrete needs to be covered

The foundation is poured. Cement will dry in 3-5 days, but it will be able to reach the necessary "condition" and gain strength only in a month. To prevent precipitation from reaching the surface and not washing out the concrete, the entire surface should be covered with something, you can use plastic wrap. If you build in the summer and it is hot outside, the composition needs to be moistened from time to time so that the concrete does not crack. After 10 days you can remove the formwork.

Waterproofing the foundation

Waterproofing the foundation

Before you start building walls, you need to do waterproofing work. The base can be coated with bitumen and lay several layers of roofing material.

Masonry walls of aerated concrete blocks

After the concrete has dried, you can start building the walls of the building. In this article we will look at the process of laying walls, using the thorn-groove method. So, on the prepared surface you need to lay out the first row of blocks. Any builder knows that the first row is the most important, since others will be happy to be guided by him. When the first row is exposed unevenly, the whole building will be crooked.

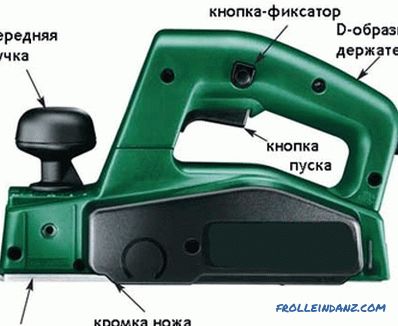

For work you will need:

- building level;

- rope or cord;

- electric or manual wall chaser;

- rubber mallet;

- brush to remove dust from the grooves;

- handsaw with large teeth;

- trowel;

- fittings Ø8 or 10 mm;

- trowel or notched trowel;

- plane for aerated concrete.

To lay the first row, experts recommend using cement mortar. Let it be longer to dry, but you can pave the first row strictly on the level. The thickness of the mortar should be at least 1 cm. To level the differences this is sufficient.

The first step is to prepare a solution. There is a simple recipe for cooking. You will need:

- shovel;

- buckets;

- trough;

- bor sand;

- cement;

- soap solution;

- water.

So, prepare a trough and put 1 cement spade, 3 sand shovels in it and mix them thoroughly.Pour water into the bucket and add 1 drop of dish detergent to it. Such soapy water will help not to settle to the bottom of the cement mixture and it will be easier to knead the solution.

Solution

Solution

Now add water to the mixture of sand and cement. There is no certain measure, you need to look at the consistency, so that the solution is not too liquid and not too thick. Stir the solution with a spade. It is important to ensure good quality and viscosity so that it fits well. Since this amount is not enough, you can do more servings. The main thing is to stick to the 1: 3 ratio.

After preparation, you can start laying. The technology is simple - you need to start building a wall from the corners. On the mortar layer, install the corner blocks on both sides of the wall. Use the mallet and level to expose them perfectly evenly. Then pull the line or cord from one corner to another. The following blocks will be laid out on it. When the wall is more than 10 m in length, a block is also placed in the middle of the row so that the cord does not sag, since it must be well stretched. After that, the first row of blocks is laid along the entire perimeter and partitions. To fit them, use a rubber mallet that needs to be tapped on the blocks. It is clear that not always the length of the wall will be a multiple of the blocks, so some of them will need to be customized in size. This is where you need a hacksaw.

Cutting aerated concrete

Cutting aerated concrete

Do not get carried away during masonry, so as not to lay the doorways.

As soon as the first row is ready, wait 2-3 hours for the solution to set. After it dries, the surface of the blocks should be treated with a plane to give it roughness, then the next row will lie much smoother. Now, instead of a solution, you can use a special glue. Apply it with a notched trowel. The second and third rows are made in the same way as the first. Only now happy to need to dress with the previous one, moving the blocks in half. You can move the block by at least 8 cm. After that, the laying process is repeated.

To dry the glue will be much faster than the mortar, so there is no need to wait long, the work should be done at a fast pace.

If you are building a big house, the walls need to be strengthened. To do this, in each 3 or 4 row you need to do the reinforcement masonry. Take a wall chaser and make 2 parallel channels in blocks. Their width should be 4 cm, and the distance from the edge of the block should be 5-6 cm. With a brush, remove dust from them and install 1-2 reinforcing bars there. Then fill all the cement mortar or glue. There is no need to wait for drying.

Sills and windows

Reinforcement

Reinforcement

Where there will be a window opening, You need to build two parallel lines. Their size should be 30 cm larger than the window frame, 15 each side. Clean the bursts of dust with a brush and insert the Ø8 or 10 mm reinforcement into them and coat the whole with a solution. When laying not worth laying openings. They are best done immediately. There is an option to cut them later, but this is a waste of material and strength.

Setting the jumpers

Installing formwork for jumpers

Installing formwork for jumpers

When things move, you you will need to install a jumper above the door and window opening. To do it right, you need:

- Lay a board above the window.

- Outside, make blocks 15 cm thick.

- Inside blocks, 10 cm thick.

- In the center, a block 15 cm thick, sawn in half.

- Make a skeleton of Ø12 mm reinforcement.

- Install the finished structure between the blocks.

- It remains to pour all the concrete.

Doorways can be made in the same way, although there are other options for constructing lintels. It can be made of reinforced concrete, metal corners and poured concrete, making formwork.

You can buy ready-made jumpers that are easy to install.

Arm-belt

Arm-belt for aerated concrete

Arm-belt for aerated concrete

When masonry fits by the end, the last row needs to be strengthened by organizing armopoyas. Thanks to him, you can ensure the integrity of the structure. In order to fill in the armored belt, a formwork should be formed from blocks with a thickness of 10 cm along the perimeter of all walls, laying them parallel to each other. In the resulting groove you need to lay reinforcement. After that, prepare the concrete and pour all around the perimeter.

To simplify the task of installing a roof rack, you can insert threaded metal studs into the armored belt. They can be welded to the fixture. It is important to adhere to exact dimensions so that they rise to the same level. By doing this, installing a power plate will be much easier.

Installation of floor slabs

When building a high-rise building, you need to make a floor that separates the floors. It can be made of wood, metal, concrete and reinforced concrete slabs. The overlap must necessarily rely on armopoyas.If the walls of the house are separated from each other by less than 6 meters, you can use aerated concrete slabs, which have the same properties as the walls of the gas block. Plates are installed on the reinforced belt, the joints between the plates are filled with mortar. The ends of the plates outside you need to close the clumsy blocks.

It is clear that you yourself will not be able to raise concrete slabs, so for work you will need heavy equipment - namely, a crane that will lift the plates to the desired height. You need to guide the slab to properly install it.

Overlapping the house with wooden beams

Overlapping the house with wooden beams

Another type of flooring is to use wooden beams. Their height can be 150-300 mm, and width - 100-250. Their ends should be cut at an angle of 60-80˚, treated with antiseptic and resin. After that, these ends turn into ruberoid and fit into niches to a depth of 150 mm. In this case, the gap between the beam and the wall remains 30-50 mm. They need to be installed in increments of 600-1500 mm. Then the crate is made and the floor is laid.

Such overlappings are of different types:

- basement - the overlap between the basement and the first floor;

- the intermediate floors - the separating floors;

- the attic floors - between the floor and the attic;

- attic - separates the floor of the house from the attic.

Before you make a roof, you need to make an attic or attic floor, depending on the type of roof.

Roof installation

The roof of the house of aerated concrete

The roof of the house of aerated concrete

The last stage of the construction of the box house - the construction of the roof. First of all, you need to decide what kind of roof to do, as they are made into the following types:

- single-shed roof;

- gable roof;

- mansard roof .

What roof do you choose yourself? The main thing that needs to be done in any type of roof is to perform waterproofing, thermal insulation and vapor barrier works.

If you cost a mansard roof, then you need to take care of noise insulation too.

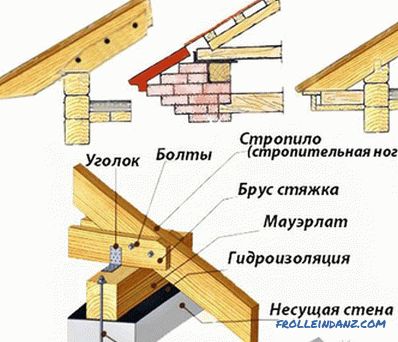

Consider a common gable roof device. So, on the prepared studs from metal along the perimeter, you need to install a mauerlat - timber, which will serve as a support for the rafters. At this stage, you need to lay under the beam 1 or 2 layers of roofing material for waterproofing. Now you need to attach the rafters to the mauerlat, with a section of 7 * 15 cm. You can attach rafters to the beam in different ways, which are shown below.

Connection of a power plate with a rafter foot

Connection of a power plate with a rafter foot

The upper part of the rafters overlaps each other so that the edge one rafter overlapped the edge of another. Then they need to be fastened with nails or bolts. To reinforce the design, parallel rafters are interconnected by means of a board.

To distribute the load and strengthen the rafters, you need to fasten them together with a crossbar. These are beams with a section of 5 * 15 cm, which must be nailed to the rafters. They need to fix a little above the middle of the roof. And in order to give additional strength to the roof and avoid sagging of the truss system, you must also install vertical racks.

After that, you need to fix the waterproofing layer on top of the rafters. Under a waterproofing the heater, mineral wool or polyfoam is fixed. And in the end you need to lay a vapor barrier, attaching it with slats to the rafters. It remains to make the crate, gable and lay the roofing material.

Today, roofing materials are very diverse, slate is already the last century. Now your roof can be not only reliable, but also beautiful. As the material you can choose:

- metal tile;

- ceramic tile;

- bituminous tile;

- decking;

- composite tile;

- cement-sand tile.

Finished house from a gas block

Finished house from a gas block

After the roof has been completely sheathed with roofing material, Your home construction work has been completed. But this is far from the end, because you still have a lot to do: making the floor, partitions, interior work, covering the walls outside, making communications, installing doors and windows, and much more. But you have already done the main work - the finished box of the house from the gas block has already been erected.And most importantly, you built this house yourself!

Video

Watch an animated video that shows how to build a house of aerated concrete:

The author of this video tells about how he built a house of aerated concrete:

Photos

House of gas blocks before finishing

House of gas blocks before finishing

House before finishing

House before finishing

Decorating the house with decorative brick

Decorating the house with decorative brick

House of gas-block

House of gas-block

Two-storey house

Two-storey house

House with an attic

House with an attic

House of gas blocks with attic

House of gas blocks with attic

Garage with a room on the second floor same

Garage with a room on the second floor same