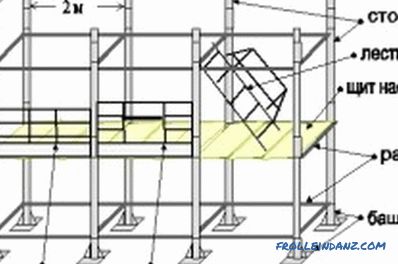

A variety of equipment is used during construction, but scaffolding is indispensable. They allow to carry out high-altitude work, workers are able to be in complete safety at the desired height. The scaffolding is convenient for finishing the facade, for filing the eaves, for installing windows.

Wood scaffolding.

The cost of this construction is high, and the forests themselves are usually required only during construction. Therefore, it is more profitable to make scaffolding with your own hands. To do this, you can use metal or wood, the work itself is not too complicated, but it requires compliance with all stages.

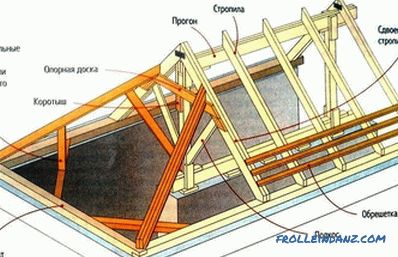

Constructive elements of scaffolding

When deciding how to make scaffolding with your own hands, you must first decide which schemes will be used. The design itself can be made of wood or metal.

The main structural elements:

Types of wood scaffolding.

- supporting struts of the frame;

- horizontal, diagonal struts, which ensure the strength of forests;

- special jumpers for flooring;

- a flooring that comes off the planks;

- a special fence that should not interfere with the work, but at the same time guarantee safety;

- a ladder (stepladder) that is necessary for ascent and descent.

Fasteners can be different, it all depends on what materials are used for manufacturing.

Wood scaffolding

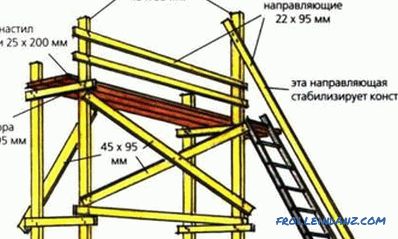

How to make wood scaffolding? The scheme is extremely simple, any master has materials and tools, special experience is not required. Boards after construction can be used for other purposes . The construction of the tree itself can have the following parameters:

- height is up to 6 m, it is no longer recommended to make it;

- between the support posts a distance of 2-2.5 m is observed;

- The width of the flooring of boards is usually 1 m.

Construction elements of scaffolding.

Galvanized nails and self-tapping screws are used as fasteners, metal corners can be used to strengthen the structure.

To perform the work it is required to prepare the following materials:

- Cutting boards, whose thickness is from 50 mm, width - from 100 mm. For racks, stops, round timber can be used or a usual wooden bar of 10 * 10 cm.

- For fencing, the spacers will suit a board with a thickness of 30 mm.

- For jumpers, flooring board is used with a thickness of 50 mm.

- Experts recommend that nails be used for fasteners, as self-tapping screws may not be as reliable.

As tools, you should prepare:

- saw;

- hammer;

- screwdriver;

- construction level .

From attaching racks to installing stairs

How do you make scaffolding yourself? It is enough to observe the following stages of work:

Installation of construction timber.

- First you need to fasten the racks. For this, diagonal braces are used, they are placed on 4 sides. This will be the framework of the first level, it must be made as reliable and stable as possible. If the nails are not enough, you can use metal corners. Before starting further work, sustainability is required to check.

- Many are concerned about how to make scaffolding safe. It is important to choose durable building material, to observe the recommended distances, to securely fasten all the elements. Cutting boards jumpers are mounted at the desired height, it is determined on the basis of the size of the forest. The height of the jumpers is also influenced by what level of work is supposed to be at.

- On the lintels there are boards for flooring. It is necessary to take only whole boards, cracks, defects are not allowed. The thickness of the board should not be small, since several people can work on the flooring at once, stand materials, tools. Too long boards are best not to take to increase the reliability of the flooring.

- A fence board must be nailed. The height is determined so that the person on the floor can work freely, while his safety is not threatened. As a rule, such barriers are placed at the belt level.

- Strong wooden bars are selected for the supports, although strong boards with the required thickness are also suitable.

- Next, the ladder is attached. In this case, you can use different design options. Most often these are boards that are nailed from the side of the scaffolding. The step should be sufficient to climb and descend the stairs so conveniently. You can apply the usual metal or wooden ladder, stepladder.

Advantages and disadvantages of improvised structures

Are there any advantages in making scaffolding with your own hands? It must be remembered that the scaffolding is a bulky construction that requires space to be placed. After using the forest it is necessary to disassemble and store somewhere, a lot of space is required for them. If there are farm buildings of the required area, then there is no such problem, but what if there is no such place? Then the scaffolding is better not to do it yourself and not to buy, and rent. The cost of rent is not too high, but the need to store the structure somewhere disappears.

If the structure is assembled from wood, then it is necessary to take into account the peculiarities of this material. Even if the board after disassembly is where to store, then we must remember that after removing the screws or nails, the integrity of the board is lost, the quality will no longer be the same as the whole board. It must be remembered that during construction the surface of the structure is stained with paint or mortar.

If building scaffolding is needed only for a short time period, then after dismantling the boards it is possible to find a use.

You can use them as a last resort to light a fire or a stove. It makes no sense to keep the boards for a long time, they need to find an application, since they can rot away even in a shed during prolonged storage.

Self-made metal structures have much more advantages. After use, they can be disassembled and rented, which will not only pay for the construction costs, but also bring profit. The strength of the metal structure is higher, it is more convenient to work, they are more stable. Among the minuses of the self-made construction it is necessary to note that it can only be used up to the level of the 2nd floor, maximum to the level of the attic above the second floor. Factory scaffolding can be much higher, but special technologies and fasteners are used for their manufacture, which is impossible at home.

Of the minuses of self-production, it should be noted that the construction is necessary only at the time of building the house. After that, it is no longer required, but the money and time for manufacturing has already been spent. The weight of the structure can be significant, which means that site preparation is required, and this is again material costs.

So are there any advantages of an independent structure? Scaffolding with their own hands can be made when work is being done with a small private house. In this case, the purchase of a ready-made design is just a waste of money. You can make your own forests when the structure is small.

Didn't find the answer in the article? More information on the topic: